High-corrosion-resistance composite coating and preparation method and application thereof

A composite coating and high corrosion resistance technology, applied in the field of electroplating, can solve the problems of unsatisfactory anode electrolytic corrosion resistance, affect the anode electrolytic corrosion resistance, and fail to meet the requirement of no pores, etc., to improve the salt water anode electrolytic corrosion resistance , Improve the anti-fretting friction and corrosion performance, and maintain the effect of electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In a typical implementation of the present invention, the preparation method of the above-mentioned high corrosion resistance composite coating comprises the following steps:

[0029] (6) Carry out pre-plating treatment for the parts to be plated;

[0030] (7) Place the piece to be plated after the treatment in step (1) in a sulfur-free and non-porous nickel ion plating solution at 50-65° C., the piece to be plated is the cathode, and the sulfur-free and non-porous Porous nickel layer, washed with water for many times;

[0031](8) Place the piece to be plated after the treatment of step (2) in the palladium ion-nickel ion plating solution of 45-55° C., obtain a high corrosion-resistant palladium-nickel alloy layer through electrodeposition, and carry out repeated steps with deionized water cleaning;

[0032] (9) placing the treated piece to be plated in a platinum plating solution at 45-55°C through step (3), obtaining a platinum layer through electrodeposition, and c...

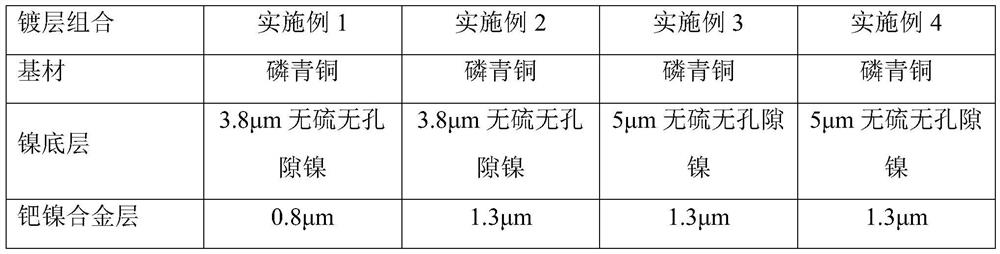

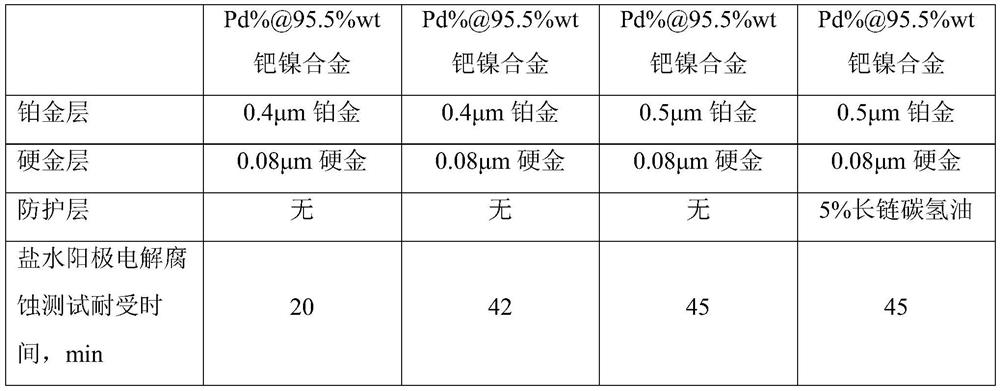

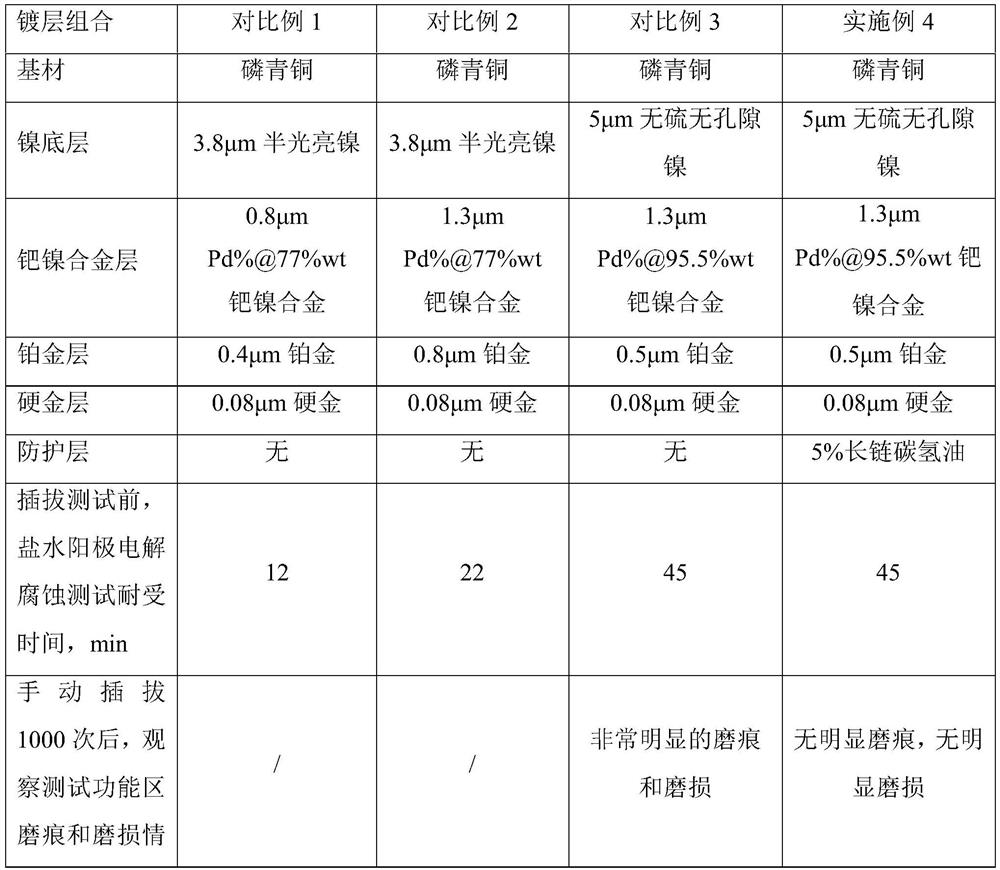

Embodiment 1

[0040] A composite coating with high corrosion resistance, the coating includes a nickel layer, a palladium-nickel alloy layer, a platinum layer and a hard gold layer which are sequentially electroplated on the surface of a piece to be plated. Wherein, the thickness of the nickel layer is 3.8 μm, the thickness of the palladium-nickel alloy layer is 0.8 μm, the thickness of the platinum layer is 0.4 μm, and the thickness of the hard gold layer is 0.08 μm.

[0041] The preparation method of the above-mentioned high corrosion resistance composite coating comprises the following steps:

[0042] (1) Carry out pre-plating treatment for the parts to be plated;

[0043] (2) Place the piece to be plated after the treatment in step (1) in a sulfur-free and non-porous nickel ion plating solution at 50° C., the piece to be plated is a cathode, and is deposited on the surface of the piece to be plated to obtain sulfur-free and non-porous nickel layer, washed several times with deionized w...

Embodiment 2

[0052] A high-corrosion-resistant composite coating includes a nickel layer, a palladium-nickel alloy layer, a platinum layer and a hard gold layer electroplated on the surface of a piece to be plated. The thickness of the nickel layer is 3.8 μm, the thickness of the palladium-nickel alloy layer is 1.3 μm, the thickness of the platinum layer is 0.4 μm, and the thickness of the hard gold layer is 0.08 μm.

[0053] The preparation method of the above-mentioned high corrosion resistance composite coating comprises the following steps:

[0054] (1) Carry out pre-plating treatment for the parts to be plated;

[0055] (2) Place the piece to be plated after the treatment in step (1) in a sulfur-free and non-porous nickel ion plating solution at 55° C., the piece to be plated is a cathode, and is deposited on the surface of the piece to be plated to obtain sulfur-free and non-porous nickel layers, washed several times;

[0056] (3) the piece to be plated after being processed in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com