Combined friction clutch brake with low driven system inertia of mechanical press

A technology of friction clutches and mechanical presses, which is applied in the direction of mechanically driven clutches, mutually meshing clutches, clutches, etc., which can solve the problems of physical and mental health injuries of workers, low energy utilization, and poor sensitivity of clutch actions, so as to avoid stuffy cars or Brake failure, improve action sensitivity, brake action sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

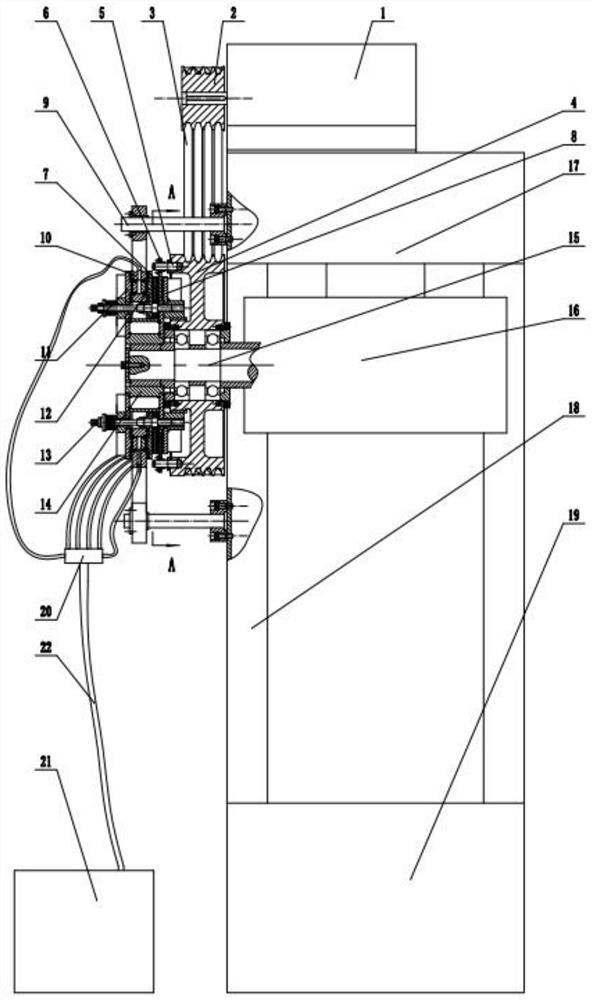

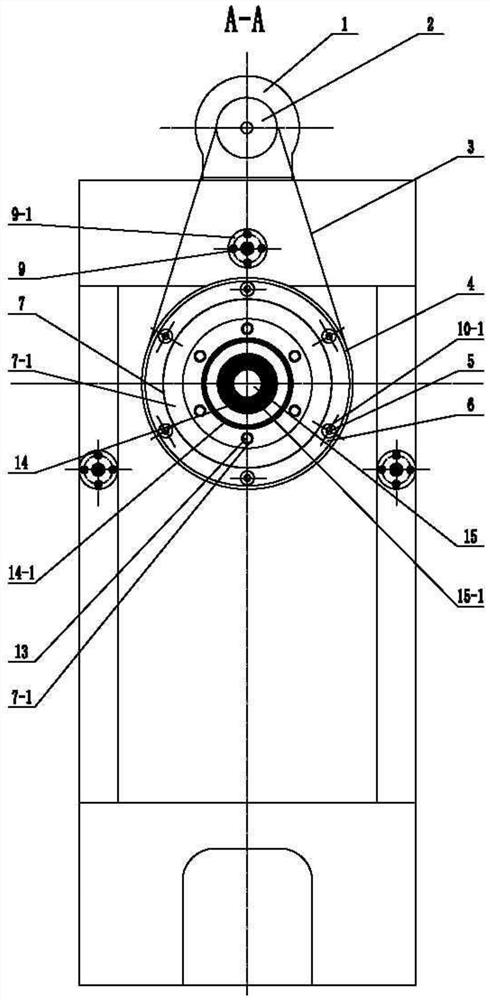

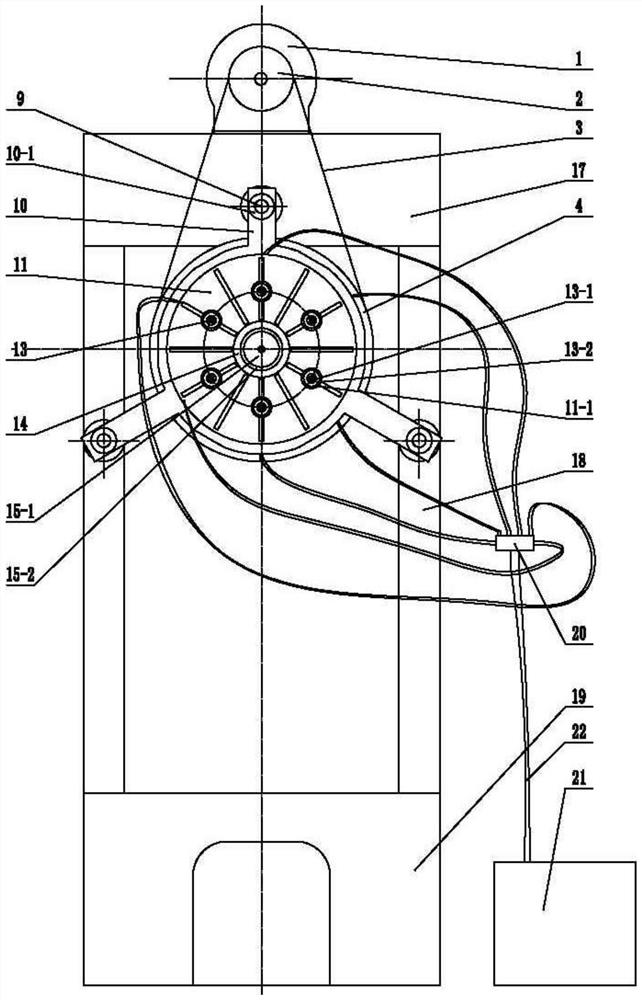

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] refer to figure 1 , figure 2 , image 3 , a combined friction clutch brake with low inertia of the driven system of a mechanical press, including a press fuselage connected by an upper beam 17, a column 18, and a base 19. The press fuselage is connected with a crankshaft 15 and its accessories. The transmission system 16, and the hydraulic pipeline system composed of hydraulic valve switch 20, oil pump 21, oil pipe 22, etc.; the friction clutch, friction brake and flywheel 4 form a whole in structure, and are located on the outer side of the press body. The brake is located on the outermost side, the friction clutch is located in the middle, the friction clutch and the friction brake are provided with an interlocking structure, the flywheel 4 is close to the press body; the drive motor 1 is installed on the upper beam 17, and the drive motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com