Special-shaped contact with self-repairing function

A special-shaped, contact technology, applied in the field of electricity, can solve the problems of reducing flux density, reducing safety factor, reducing service life, etc., to achieve the effect of reducing the voltage drop between contacts, improving connection efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

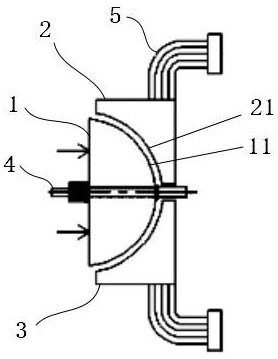

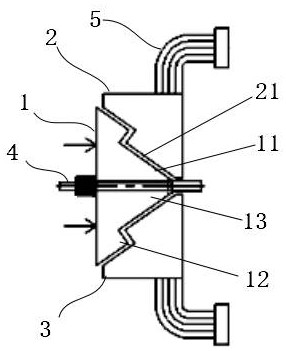

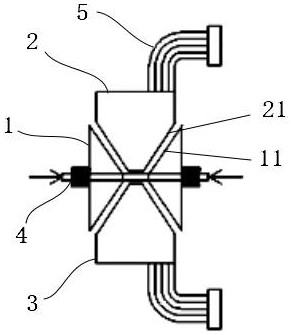

[0027] Such as Figure 1 to Figure 5 As shown, this specific embodiment provides a special-shaped contact with self-repairing function, including an upper connection terminal 2, a lower connection terminal 3 and a contact 1, the contact 1 is provided with a support core rod 4, and the support core rod 4 Pass through the contact 1 and extend into the gap between the upper terminal 2 and the lower terminal 3, the supporting core rod 4 is located between the upper terminal 2 and the lower terminal 3; the contact 1 has a contact contact surface 11. The contact contact surface 11 is a curved surface or a special-shaped slope structure composed of at least two inclined surfaces arranged at an angle. The upper terminal 2 and the lower terminal 3 have a terminal contact surface that is compatible with the contact contact surface 11 21 , the contact contact surface 11 and the terminal contact surface 21 form an engaging structure, and the upper terminal 2 and the lower terminal 3 are c...

specific Embodiment approach 2

[0029] Such as figure 1 As shown, this specific embodiment is a further improvement on the basis of specific embodiment 1, and the improvement points are: contacts 1 are provided on one side of the upper terminal 2 and the lower terminal 3, and the contact surface 11 of the contact is convex. arc-shaped surface, and the protruding direction is the same as the advancing direction of the contact 1 during crimping, and the terminal contact surface 21 is a concave arc-shaped surface. A self-occlusal structure is realized, and the contact 1 has tangential friction during crimping movement. Wherein, the contact 1 is hemispherical, and the contact surface 11 of the contact is hemispherical. In addition, the structure is an internal pressure type, that is, the contact head 1 is touched to complete the crimping action.

specific Embodiment approach 3

[0030] Such as figure 2 As shown, this specific embodiment is a further improvement on the basis of specific embodiment 1, and the improvement points are: a contact 1 is provided on one side of the upper connection terminal 2 and the lower connection terminal 3, and the contact 1 is provided with an inner engagement part 12 and the outer occlusal portion 13, the outer occlusal portion 13 is an angle structure formed by two inclined surfaces arranged at an angle, the inner occlusal portion 12 is a vertebral structure, the inner occlusal portion 12 extends inwardly and protrudes from the outer occlusal portion 13, and the inner occlusal portion 12 and the protruding direction of the outer bite portion 13 are the same as the propelling direction of the contact 1 during crimping. A self-occlusal structure is realized, and the contact 1 has tangential friction during crimping movement. The conical structure mentioned here can be a flat top (cross-section is conical or other), tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com