Aminohexenoic acid intermediate and preparation method thereof

A technology of vigabatrin and ethylene, applied in the field of medicine, can solve the problems of large discharge of post-treatment wastewater and solvent residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

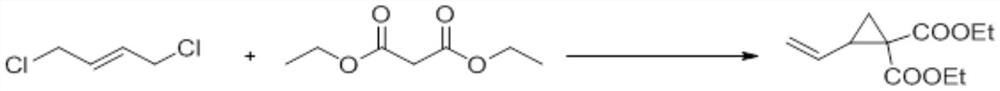

Method used

Image

Examples

Embodiment 1

[0054] 1) Reaction steps: Add 81.6Kg of 20% sodium ethoxide ethanol solution into the enamel reaction kettle, start stirring, and heat up to 55°C; weigh 40.3Kg of diethyl malonate, and add it dropwise to the above-mentioned enamel reaction kettle; Take 30Kg of trans-1,4-dichloro-2-butene and add it dropwise to the above-mentioned enamel reaction kettle, and the dropwise addition is completed in 1.5 to 2 hours; weigh 81.6Kg of 20% sodium ethylate ethanol solution, add it to the above-mentioned enamel In the reaction kettle, the dropwise addition is completed in 1 to 1.5 hours; the temperature is raised to 60°C, and the reaction is performed for 4.5 hours;

[0055] 2) Post-treatment: After the reaction is over, stop heating and cool down to 20°C; filter, transfer the mother liquor into an enamel reaction kettle, add 70g of hydroquinone, and reduce Concentrate under reduced pressure to obtain an oily substance, namely 2-vinylcyclopropane-1,1-diethyldicarboxylate. The yield was 9...

Embodiment 2

[0057] 1) Reaction steps: Add 72.6Kg of 20% sodium ethoxide ethanol solution into the enamel reaction kettle, start stirring, and heat up to 55°C; weigh 42.3Kg of diethyl malonate, and add it dropwise to the above-mentioned enamel reaction kettle; Take 30Kg of trans-1,4-dichloro-2-butene and add it dropwise to the above-mentioned enamel reaction kettle, and the dropwise addition is completed in 1.5 to 2 hours; weigh 90.6Kg of 20% sodium ethoxide ethanol solution, add it to the above-mentioned enamel In the reaction kettle, the dropwise addition is completed in 1 to 1.5 hours; the temperature is controlled at 55°C, and the reaction is 6 hours;

[0058] 2) Post-treatment: After the reaction is over, stop heating and cool down to 20°C; filter, transfer the mother liquor into an enamel reactor, add 70g of hydroquinone, and reduce the temperature at 55°C with a vacuum of not less than 0.07Mpa Concentrate under reduced pressure to obtain an oily substance, namely 2-vinylcyclopropane...

Embodiment 3

[0060] 1) Reaction steps: Add 97.9Kg of 20% sodium ethoxide ethanol solution into the enamel reaction kettle, start stirring, and heat up to 55°C; weigh 42.3Kg of diethyl malonate, and add it dropwise to the above-mentioned enamel reaction kettle; Take 30Kg of trans-1,4-dichloro-2-butene and add it dropwise to the above-mentioned enamel reaction kettle, and the dropwise addition is completed in 1.5 to 2 hours; weigh 65.3Kg of 20% sodium ethoxide ethanol solution, and add it to the above-mentioned enamel reaction kettle In the reaction kettle, the dropwise addition is completed in 1 to 1.5 hours; the temperature is raised to 65°C, and the reaction is carried out for 3 hours;

[0061] 2) Post-processing: After the reaction is over, stop heating and cool down to 20°C; filter, transfer the mother liquor into an enamel reaction kettle, add 70g of hydroquinone, and depressurize at 65°C with a vacuum degree of not less than 0.07Mpa Concentration gave an oily substance, namely 2-vinyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com