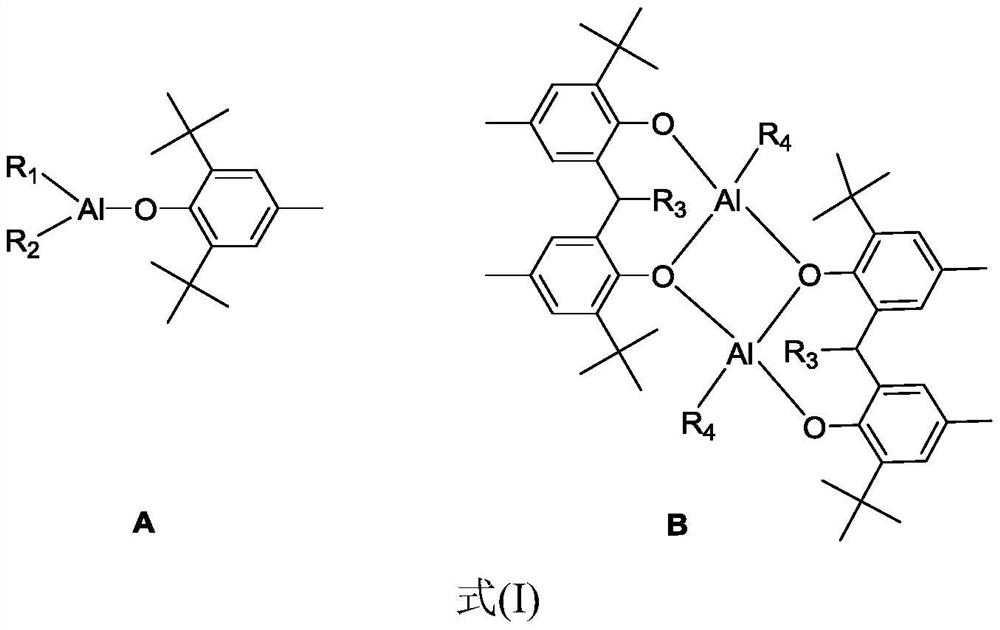

Rare earth catalyst and preparation and application thereof

A rare earth catalyst and catalyst technology are applied to polyisoprene, rare earth catalyst and its preparation, application in butadiene-isoprene copolymer, and the field of preparing polybutadiene, achieving low cost and good prevention. Aging performance, effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

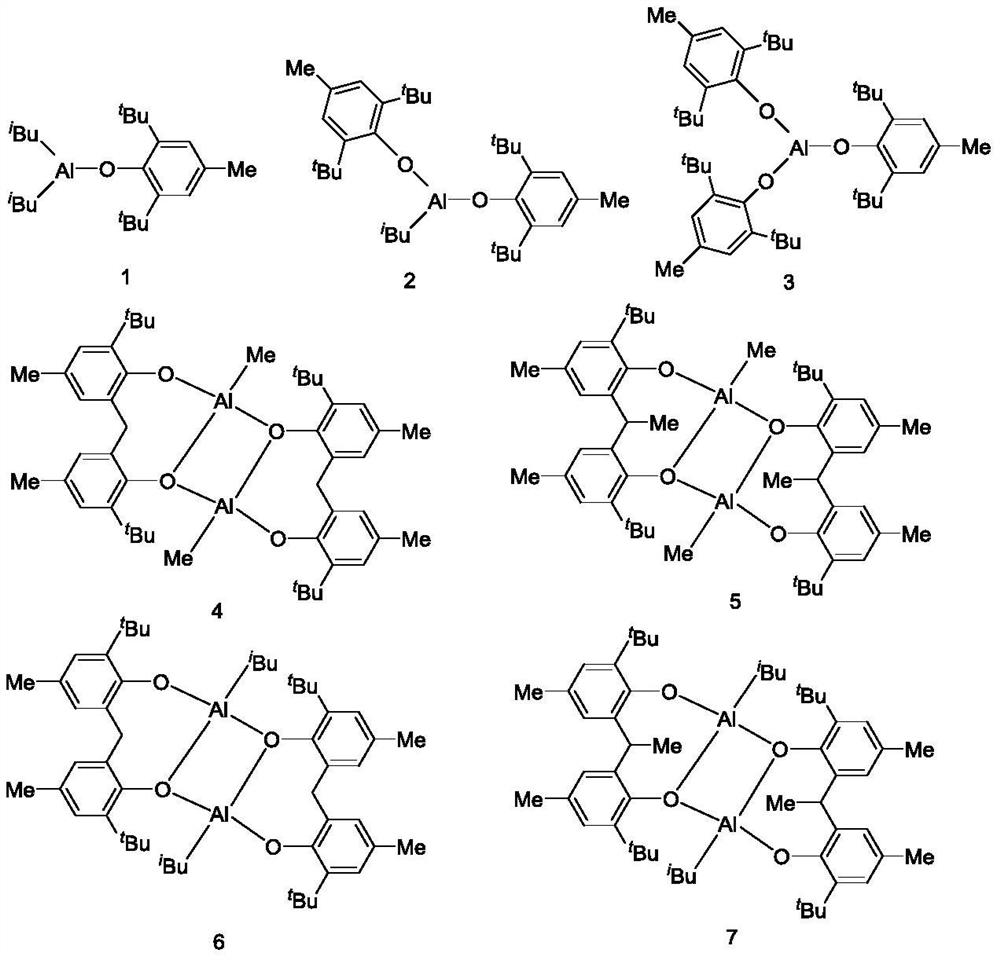

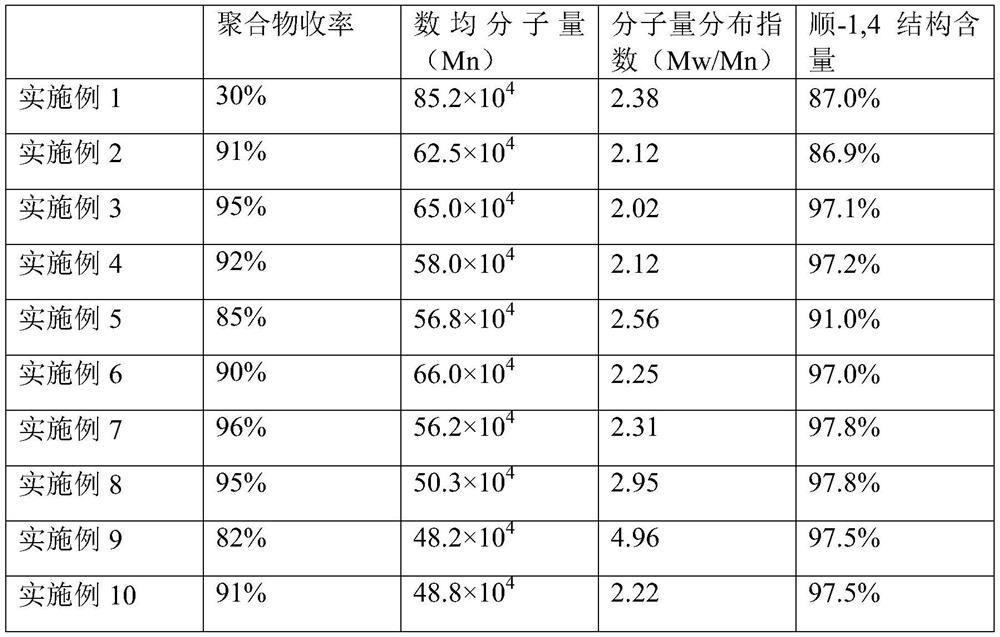

Embodiment 1

[0035] Under the protection of nitrogen, add 10 mL of isopropoxy neodymium toluene solution with a concentration of 0.10 mol / L and 15 mmol of aluminum compound 1 into the catalyst preparation device, and then react at 30° C. for 120 min to obtain a rare earth catalyst.

[0036] Under nitrogen protection, in dry polymerization reactor, add 2L monomer concentration and be the butadiene hexane solution of 100g / L, then add above-mentioned rare earth catalyst, the mol ratio of Nd element and butadiene monomer in this catalyst is 1.0×10 -4 , reacted at 60° C. for 4 h, and then added 100 mL of ethanol to terminate the reaction to obtain polybutadiene.

Embodiment 2

[0038] Under the protection of nitrogen, add 10 mL of isopropoxy neodymium toluene solution with a concentration of 0.10 mol / L and 30 mmol of aluminum compound 1 into the catalyst preparation device, and react at 30° C. for 120 min to obtain a rare earth catalyst.

[0039] Under nitrogen protection, in dry polymerization reactor, add 2L monomer concentration and be the butadiene hexane solution of 100g / L, then add above-mentioned rare earth catalyst, the mol ratio of Nd element and butadiene monomer in this catalyst is 1.0×10 -4 , reacted at 60° C. for 4 h, and then added 100 mL of ethanol to terminate the reaction to obtain polybutadiene.

Embodiment 3

[0041] Under the protection of nitrogen, add 10 mL of isopropoxy neodymium toluene solution with a concentration of 0.10 mol / L and 30 mmol of aluminum compound 1 to the catalyst preparation device, react at 30°C for 120 min, and then add 1.0 mL of a solution with a concentration of 1.0 mol / L Chlorodiethylaluminum was reacted at 50°C for 1h to obtain a rare earth catalyst.

[0042] Under nitrogen protection, in dry polymerization reactor, add 2L monomer concentration and be the butadiene hexane solution of 100g / L, then add above-mentioned rare earth catalyst, the mol ratio of Nd element and butadiene monomer in this catalyst is 1.0×10 -4 , reacted at 60° C. for 4 h, and then added 100 mL of ethanol to terminate the reaction to obtain polybutadiene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com