Lead telluride quantum dots and preparation method and application thereof

A technology of lead telluride and quantum dots, which is applied in chemical instruments and methods, electrical components, nanotechnology, etc., can solve the problems of simple preparation methods of lead telluride quantum dots that have not been reported by anyone, and the influence of material intrinsic characteristics. Wide range of applications, convenient use, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

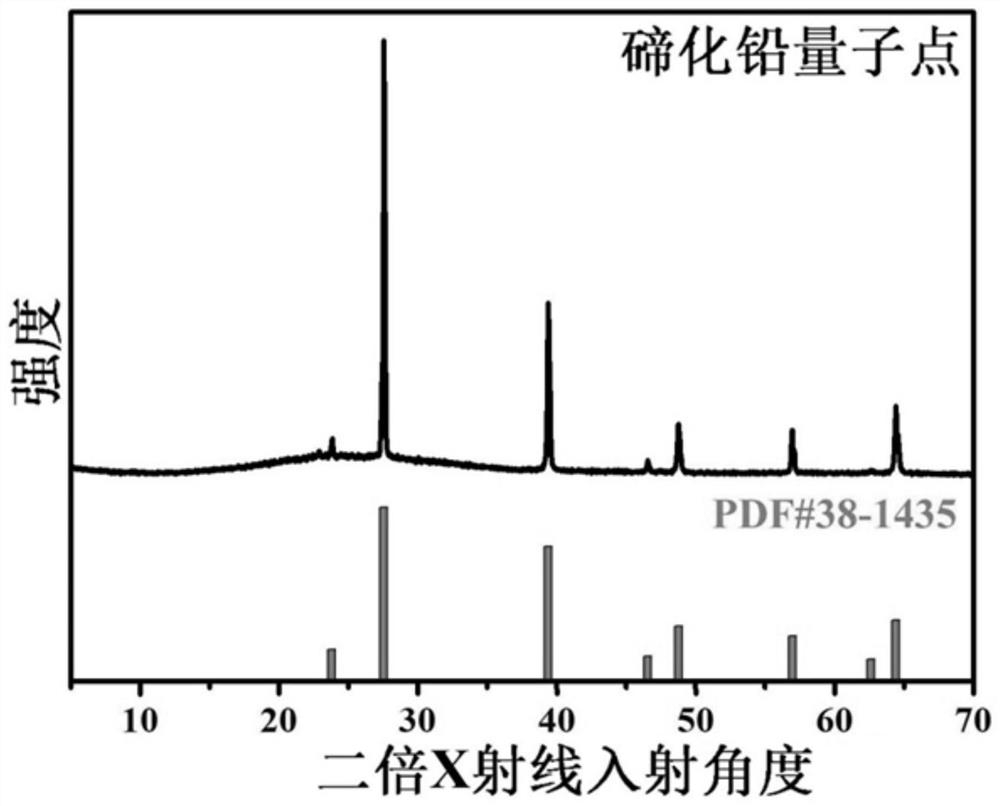

[0043] In this embodiment, the lead telluride quantum dots prepared in nitrogen methyl pyrrolidone solvent, the specific steps are as follows:

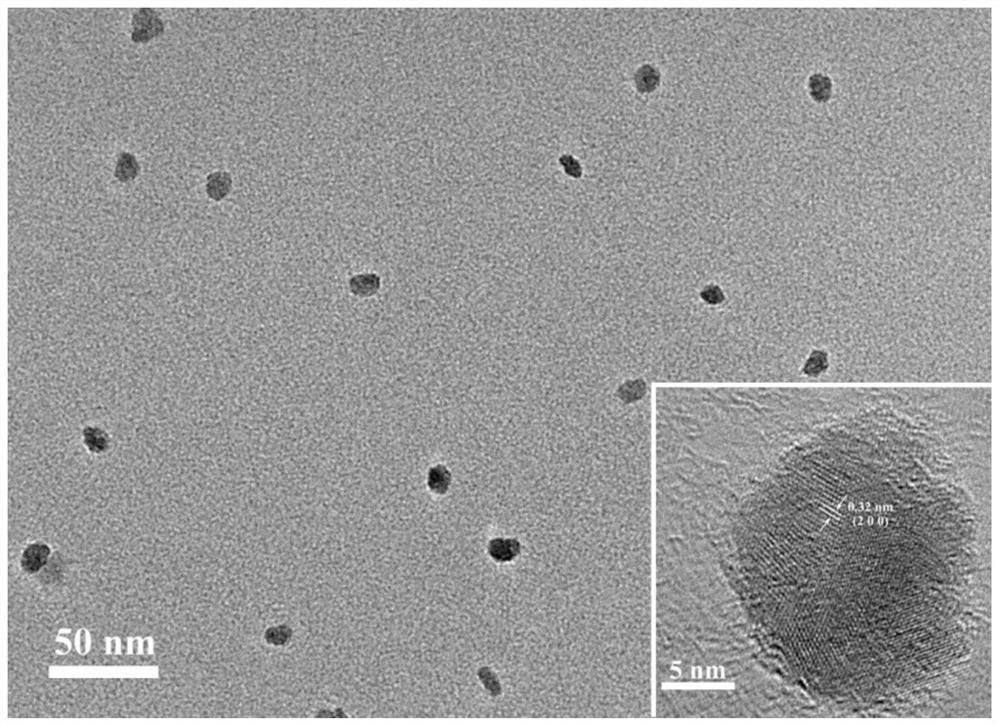

[0044] 1) Under nitrogen protection, add 500 mg of lead telluride powder to 500 ml of nitrogen methyl pyrrolidone solvent, use probe ultrasonic (600 watts) for about 8 hours in an ice-water bath environment, and then use water bath ultrasonic (350 watts) ) for about 48 hours, and the temperature of the water bath was kept constant at 10°C.

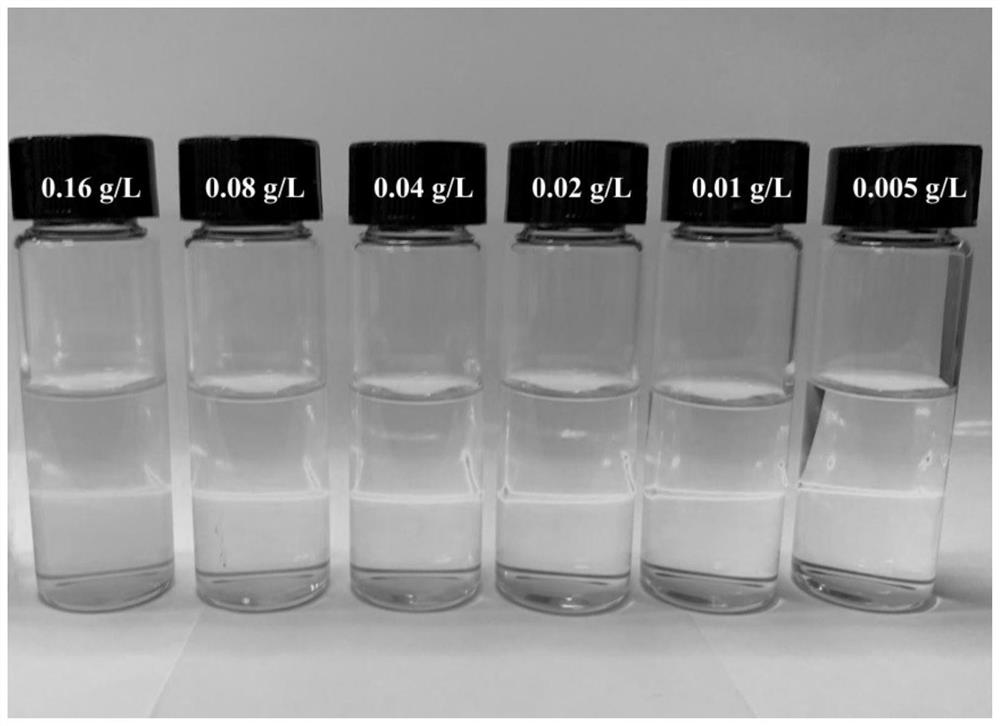

[0045] 2) After the ultrasound is completed, the lead telluride quantum dots are collected by the method of fractional centrifugation, which mainly includes: first adopting a centrifugation rate of 8000 rpm, centrifuging for 30 minutes, and taking the upper layer solution; Centrifuge for 30 minutes, and take the bottom pellet.

[0046] 3) For the precipitated lead telluride quantum dots obtained after fractional centrifugation, the solvent was removed by means of vacuum drying. The temperature of...

Embodiment 2

[0051] The lead telluride quantum dots prepared in this embodiment in dimethylformamide solvent, the specific steps are as follows:

[0052] 1) Under nitrogen protection, 400 mg of lead telluride powder was added to 200 milliliters of dimethylformamide solvent, and probe ultrasound (800 watts) was used for about 6 hours in an ice-water bath environment, followed by water bath ultrasound (250 watts) Watts) for about 72 hours, the temperature of the water bath was kept constant at 10°C.

[0053] 2) After the ultrasound is completed, the lead telluride quantum dots are collected by the method of fractional centrifugation, which mainly includes: first adopting a centrifugal rate of 9000 rpm, centrifuging for 25 minutes, and taking the upper layer solution; The centrifugation rate is centrifuged for 25 minutes, and the bottom pellet is taken.

[0054] 3) For the lead telluride quantum dot precipitation obtained after fractional centrifugation, the solvent was removed by means of v...

Embodiment 3

[0058] The lead telluride quantum dots prepared in this embodiment in dimethylformamide solvent, the specific steps are as follows:

[0059] 1) Under nitrogen protection, 5000 milligrams of lead telluride powder was added to 2000 milliliters of dimethylformamide solvent, and probe ultrasound (800 watts) was used for about 8 hours in an ice-water bath environment, followed by water bath ultrasound (350 watts) Watts) for about 72 hours, the temperature of the water bath was kept constant at 10°C.

[0060] 2) After the ultrasound is completed, the lead telluride quantum dots are collected by the method of fractional centrifugation, which mainly includes: first adopting a centrifugation rate of 9000 rpm, centrifuging for 30 minutes, and taking the upper layer solution; Centrifuge for 30 minutes, and take the bottom pellet.

[0061] 3) For the lead telluride quantum dot precipitation obtained after fractional centrifugation, the solvent was removed by means of vacuum drying. The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com