Leisure type low-fat high-protein crisp chips with taste of potato chips and preparation method of leisure type low-fat high-protein crisp chips with taste of potato chips

A technology with high protein and taste, applied in food forming, food ultrasonic treatment, food science, etc., can solve the problems of body fat accumulation, body obesity, blood sugar, high blood pressure, etc., achieve crisp taste, improve taste, and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Raw material processing: put 600g of chicken breast meat into 4wt% brine, soak for 5min under the condition of ultrasonic frequency of 20Hz, and wash with clear water. Then put the chicken breast into the mixed deodorization liquid of 120g shredded ginger and 1500mL cooking wine, then soak it for 5 minutes under the condition of ultrasonic frequency of 20Hz, then rinse it, drain the water, and twist it into a meat paste.

[0038] (2) Mixing and blending: Add 250g cornstarch, 2g TG enzyme, 0.1g ovomucin, 10g monosodium glutamate, 6g salt, 1g cinnamon powder, 15g swelling agent, 6g black pepper to the meat puree prepared in step (1) powder, and mix evenly to obtain a mixed material.

[0039] (3) beating and rubbing: the mixed material obtained in step (2) was crushed for 10 minutes, rubbed, and rubbed into a cylindrical strip with a diameter of 6 cm.

[0040] (4) Cooking: Arrange the cylindrical strips obtained in step (3) on a steamer rack, and cook for 15 minutes. ...

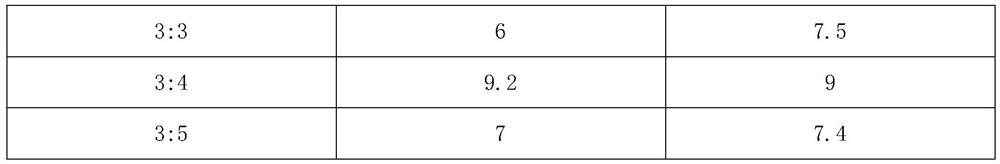

Embodiment 2

[0045] (1) Raw material processing: put 300g of chicken breast meat and 400g of pork tenderloin into brine with a concentration of 5wt%, soak for 7min at an ultrasonic frequency of 23 Hz, and wash them with clean water. Then put the chicken breast into the mixed deodorization liquid of 140g shredded ginger and 1700mL cooking wine, soak it for 5min under the condition of ultrasonic frequency of 20Hz, then rinse it, drain the water, and twist it into a meat puree.

[0046] (2) Mixing and blending: add 300g potato starch, 3g TG enzyme, 0.2g ovomucin, 15g monosodium glutamate, 8g salt, 2g cinnamon powder, 20g swelling agent, 6g cumin to the meat puree prepared in step (1) Powder, 2g chili powder, mix evenly, obtain mixed material.

[0047] (3) beating and rubbing: the mixed material obtained in step (2) was crushed for 15 minutes, rubbed, and rubbed into a cylindrical strip with a diameter of 7 cm.

[0048] (4) Cooking: Arrange the cylindrical strips obtained in step (3) on a ste...

Embodiment 3

[0053] (1) Raw material processing: put 240g of pangasius, 240g of chicken breast and 320g of pork tenderloin into brine with a concentration of 6wt%, soak for 5min under the condition of ultrasonic frequency of 25Hz, and wash with clear water. Then put the chicken breast into the mixed deodorization solution of 180g shredded ginger and 2000mL cooking wine, soak it for 10min at an ultrasonic frequency of 20Hz, then rinse it, drain the water, and twist it into a meat paste.

[0054] (2) Mixing and blending: Add 350g potato starch, 4g TG enzyme, 0.5g ovomucin, 20g monosodium glutamate, 10g salt, 3g cinnamon powder, 25g swelling agent, 6g cumin to the meat puree prepared in step (1) Powder, 4g black pepper powder, mix evenly, obtain mixed material.

[0055] (3) beating and rubbing: the mixture obtained in step (2) was crushed for 20 minutes, rubbed, and rubbed into cylindrical strips with a diameter of 8 cm.

[0056] (4) Cooking: Arrange the cylindrical strips obtained in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com