Preparation method of personalized biphase condylar scaffold

A technology of condyle and condyle head, which is applied in the field of preparation of personalized biphasic condylar stents, can solve the problems of inability to restore the shape of the condyle and other complications in the bone donor area, shorten the operation time, reduce the occurrence of complications, Solve the effect of mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

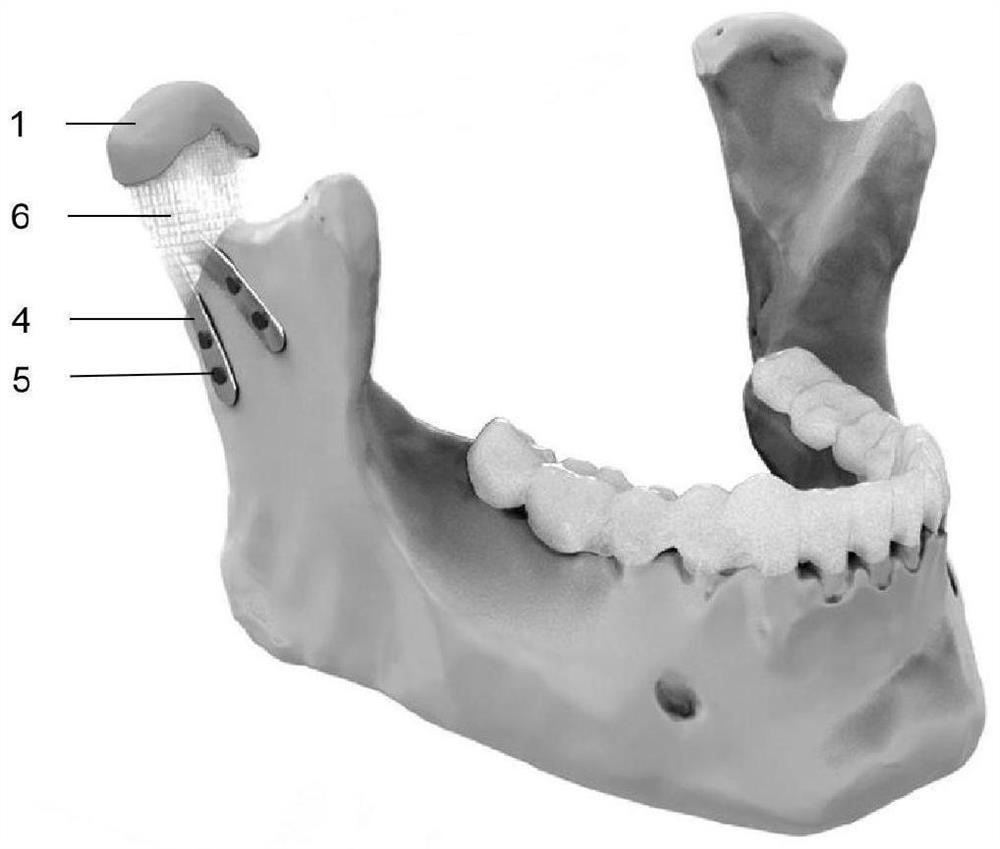

[0024] The structure of a kind of personalized biphasic bionic condyle support of the present invention, as figure 1 with figure 2 As shown, it includes a bone phase bracket 3 and a cartilage phase bracket 1 , the bottom of the bone phase bracket 3 is connected to a retention handle 4 , and a titanium nail hole 5 is provided on the retention handle 4 .

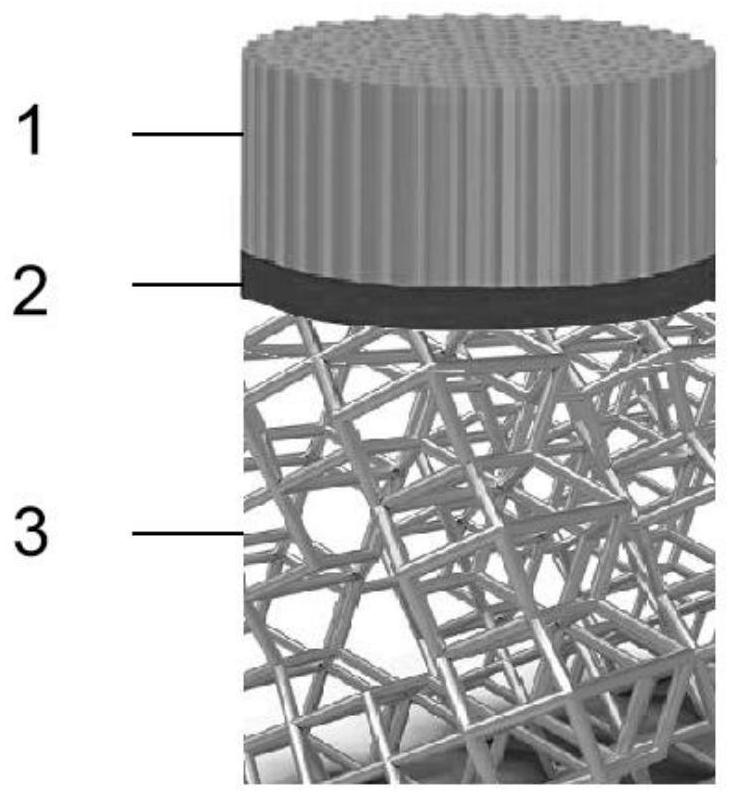

[0025] The bone phase support 3 includes a condylar head and a condylar main body 6. A dense layer 2 is arranged on the surface of the condylar head. The thickness of the dense layer 2 is 380-420 μm. Mesh holes are arranged on the dense layer 2, and the diameter of the mesh is not greater than 100 μm.

[0026] The outer surface of the main part of the condyle 6 is provided with diamond-shaped holes, the diameter of which is 400-600 μm, and the porosity of the diamond-shaped holes is 65-75%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com