Fusion cage

A fusion device and extension technology, which is applied in the field of medical supplies, can solve problems such as mismatching mechanical properties, high elastic modulus, and vertebral body subsidence, and achieve the effects of improving recovery, reducing elastic modulus, and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

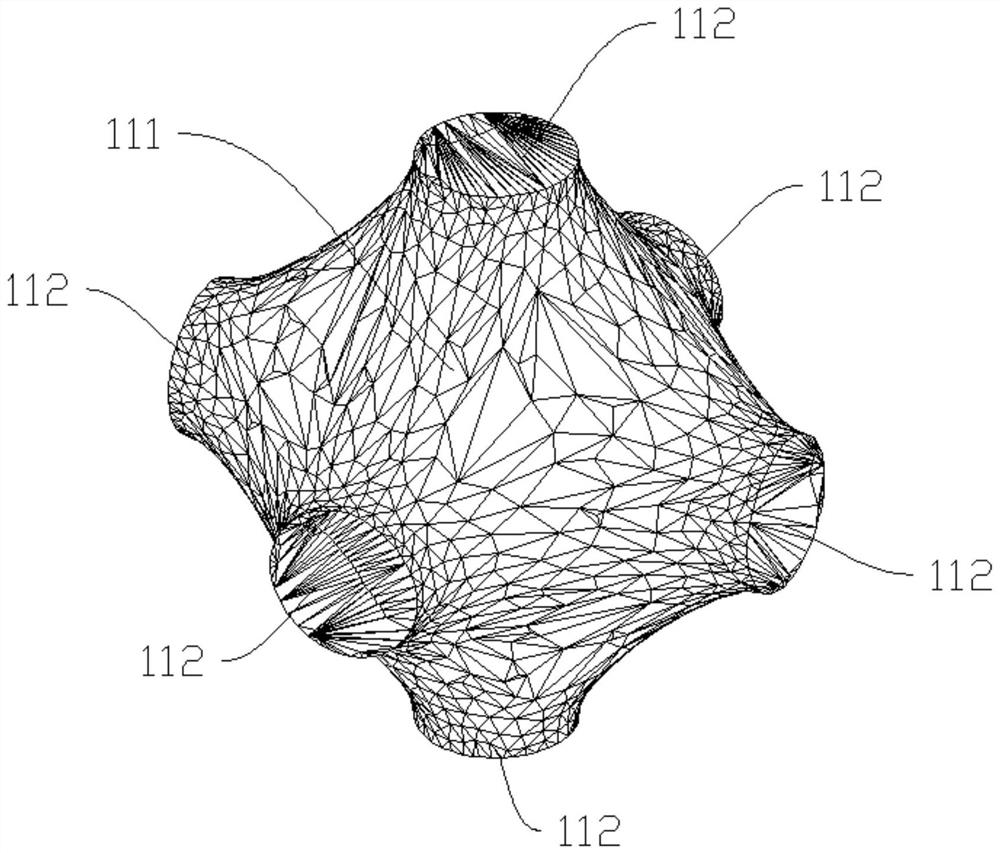

[0032] refer to figure 1 and Figure 7 As shown, the overall structural optimization of the structural unit can be obtained by parametric design, that is, the structure and relative positional relationship between the lower substrate 111 and the extension part 112 in this embodiment can be obtained by parametric design, and the parametric formula is: Among them, L is the size parameter of the pore unit, and C is the porosity parameter. The structural unit formed by modeling using this parametric formula has a spherical base 111, and several extensions 112 are evenly distributed along the outer circumference of the spherical base 111. Two adjacent The structural units are connected by extensions 112, and several structural units are connected to form a flat porous structure. It should be noted that the connection between the two extensions 112 of two different structural units is also smooth. Connection, that is, the porous structure inside the porous structure is smooth and ...

Embodiment 2

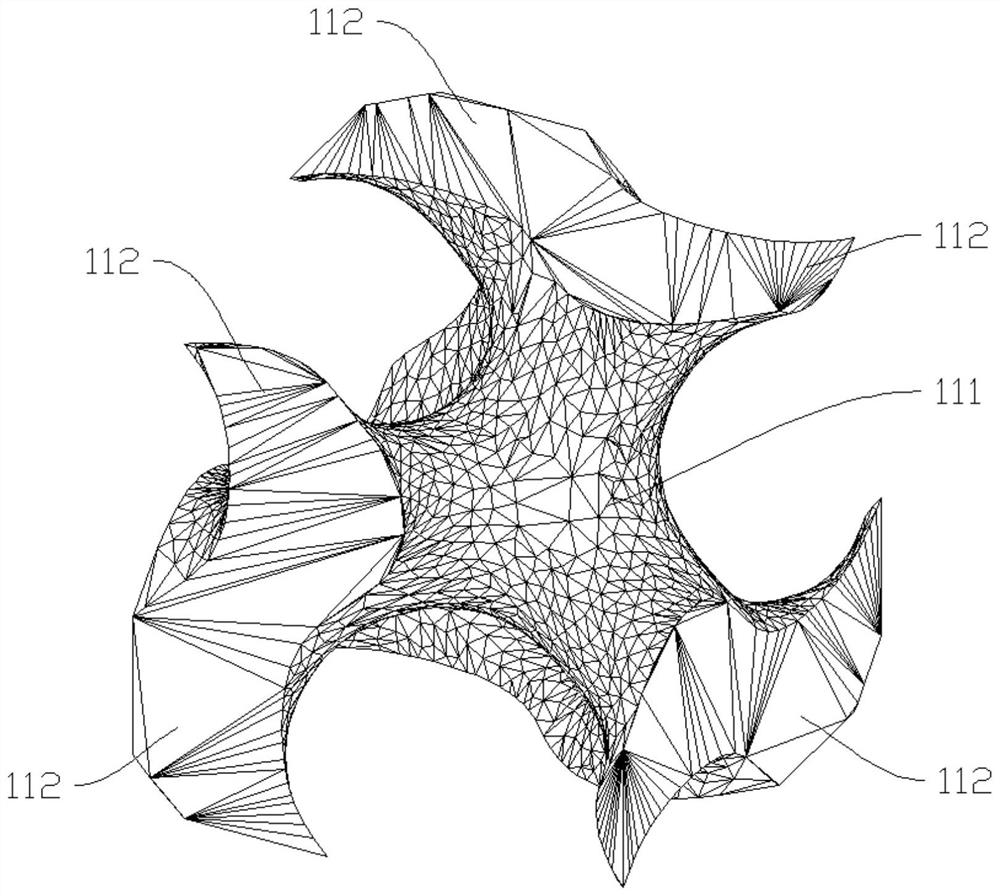

[0034] refer to figure 2 and Figure 7 As shown, the overall structural optimization of the structural unit can be obtained by parametric design, that is, the structure and relative positional relationship between the lower substrate 111 and the extension part 112 in this embodiment can be obtained by parametric design, and the parametric formula is: Wherein, L is the size parameter of the pore unit, and C is the porosity parameter. For the structural unit formed by modeling with this parameterized formula, at least two adjacent extensions 112 on the same substrate 111 intersect and surround the surface of the substrate 111. A pore structure is formed, that is, a single structural unit has at least one pore structure. When several structural units are combined to form the main body 10 of the porous structure, a pore structure may be formed between two adjacent structural units, or no pores may be formed. structure, in this embodiment, the side of the extension part 112 that...

Embodiment 3

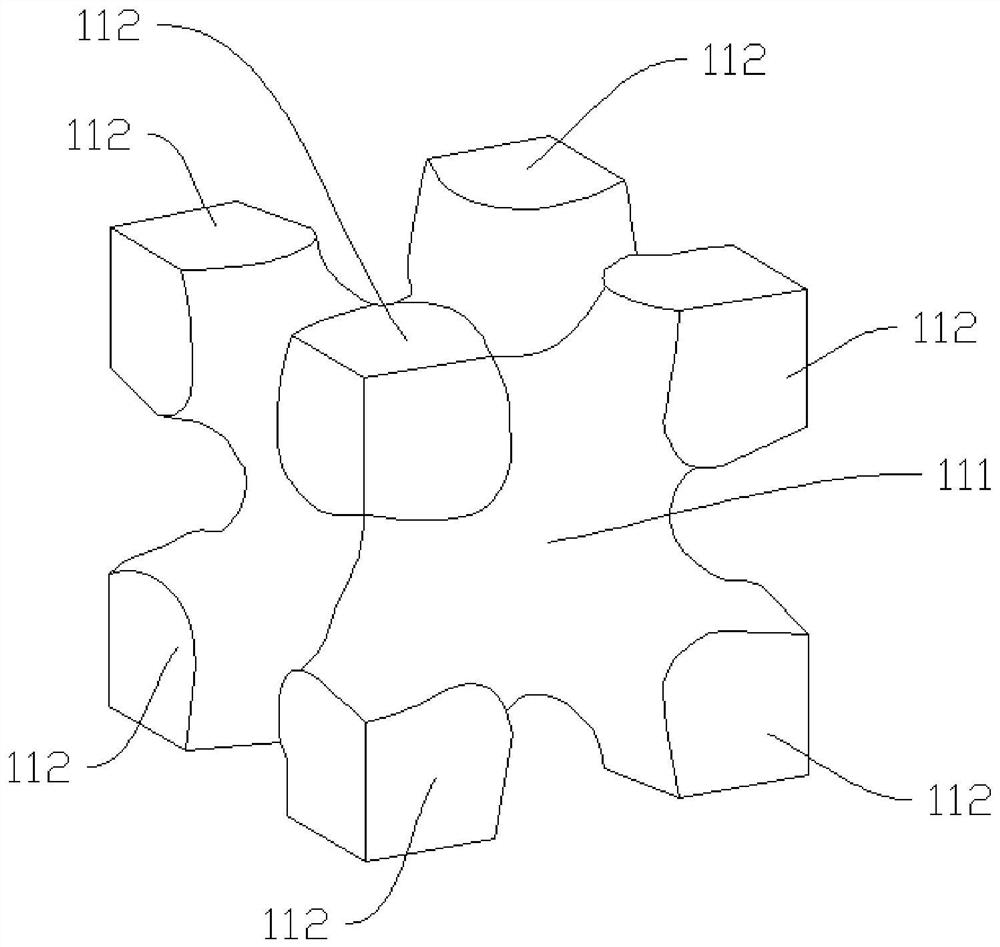

[0036] refer to image 3 and Figure 7 As shown, the overall structural optimization of the structural unit can be obtained by parametric design, that is, the structure and relative positional relationship between the lower substrate 111 and the extension part 112 in this embodiment can be obtained by parametric design, and the parametric formula is: Wherein, L is the size parameter of the pore unit, and C is the porosity parameter; in the structural unit formed by modeling with this parameterized formula, eight extensions 112 extend outward from the outer surface of the matrix 111 respectively, and the eight extensions 112 Uniformly distributed along the circumference of the sphere, specifically, the extension portion 112 includes a cylindrical portion and a vertebral portion, one end of the cylindrical portion is smoothly connected to the base 111, and the other end is smoothly connected to the vertebral portion, and the vertebral portion has a first end surface, a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com