Antimony-containing soldering-flux-free solder wire and preparation method thereof

A solder wire and flux technology, used in welding equipment, manufacturing tools, welding media, etc., can solve the problems of not being completely decomposed, affecting product life, solder joint corrosion, etc., to improve life and reliability, and improve thermal and electrical conductivity. rate, the effect of reducing the soldering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

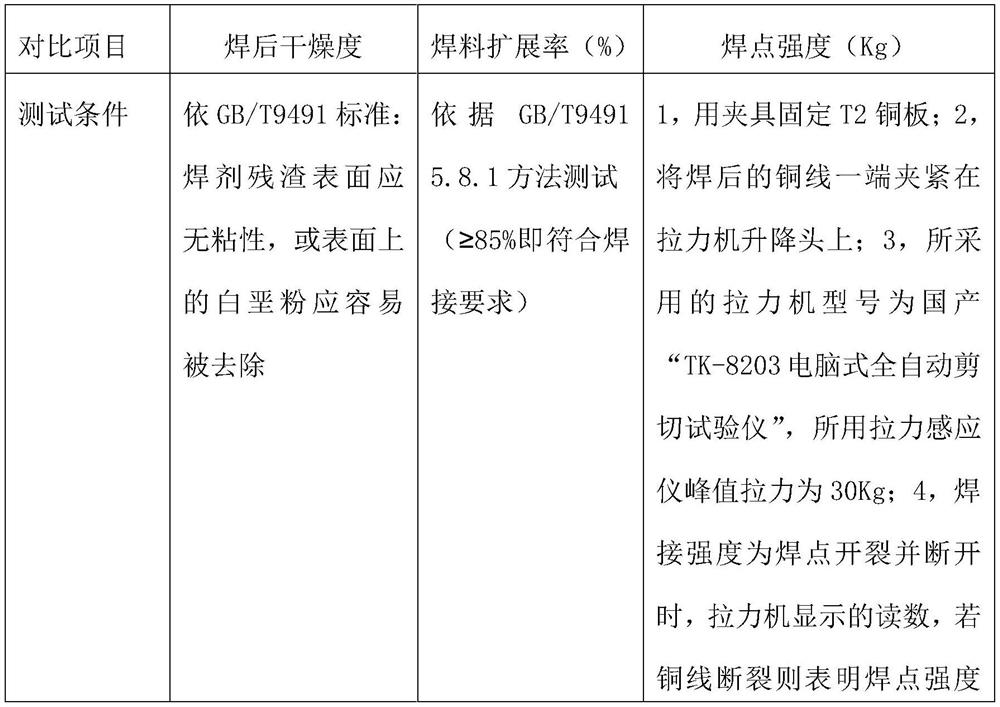

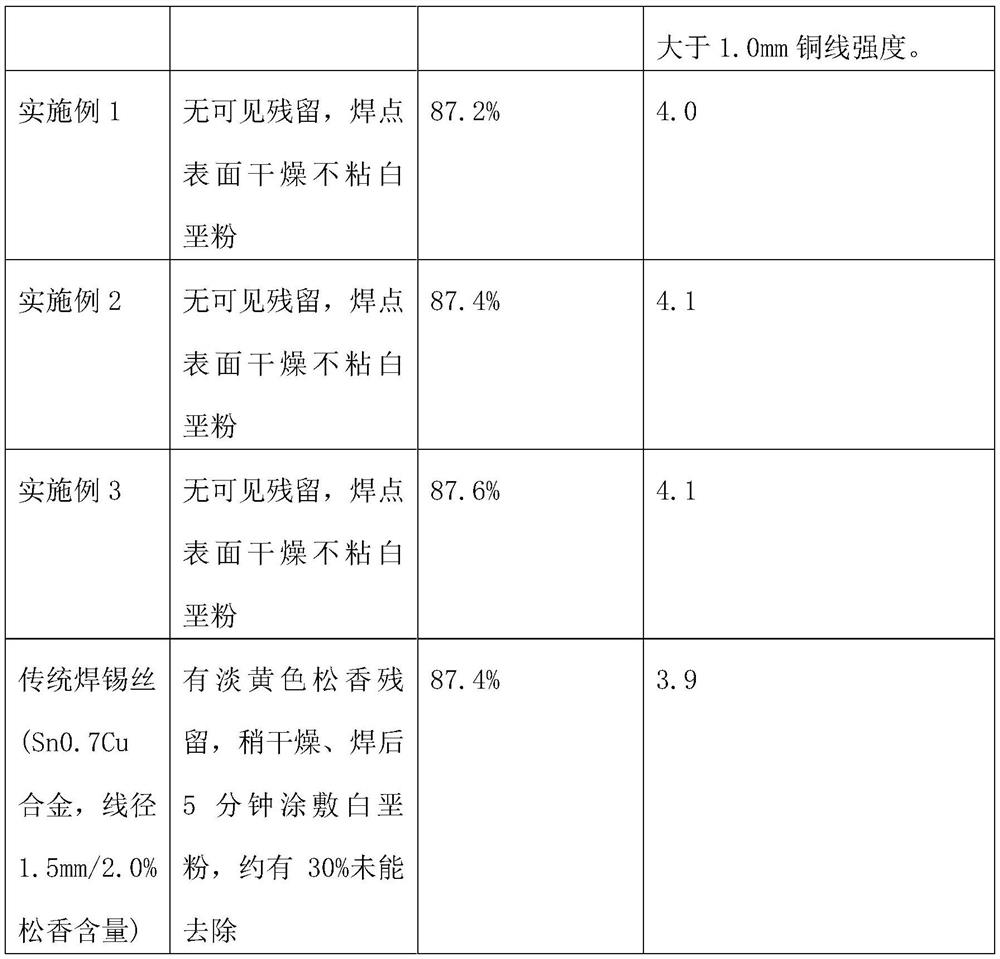

Examples

Embodiment 1

[0018] An antimony-containing flux-free solder wire includes 10% of the first component and 90% of the second component in terms of mass percentage.

[0019] Weigh the first component of 4Kg of dibasic acid ester and 6Kg of antimony-copper compound powder, with a median particle size of 1.0 microns;

[0020] Weigh 100Kg of electrolytic tin whose purity of the second component is 99.95%;

[0021] Its preparation method comprises the following steps:

[0022] Step 1, mixing the dibasic acid ester and antimony-copper compound powder in the first component evenly, heating to 90-105°C, and keeping stirring continuously to obtain the first component;

[0023] Step 2: Pour the above-mentioned homogeneously mixed first component into an injection barrel with heat preservation and stirring functions for later use;

[0024] Step 3, put the above-mentioned weighed second component of electrolytic tin into an intermediate frequency heating furnace, keep the temperature range of 380-400°...

Embodiment 1

[0027] Step 6, the extruded product is passed through a wire drawing die to control the thickness of the wire diameter, and the final wire diameter is 1.5mm, that is, the antimony-containing flux-free solder wire of the present invention is obtained as the sample of Example 1 for testing.

Embodiment 2

[0029] An antimony-containing flux-free solder wire includes 15% of the first component and 85% of the second component in terms of mass percentage.

[0030] Weigh the first component of 6Kg of dibasic acid ester and 9Kg of antimony copper compound powder, particle size is 1.0 micron;

[0031] Weigh 100Kg of electrolytic tin whose purity of the second component is 99.95%;

[0032] Its preparation method comprises the following steps:

[0033] Step 1, mixing the dibasic acid ester and antimony-copper compound powder in the first component evenly, heating to 90-105°C, and keeping stirring continuously to obtain the first component;

[0034] Step 2: Pour the above-mentioned homogeneously mixed first component into an injection barrel with heat preservation and stirring functions for later use;

[0035] Step 3, put the above-mentioned weighed second component of electrolytic tin into an intermediate frequency heating furnace, keep the temperature range of 380-400°C, and continue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com