Multi-level micro-nano mechanical structure for enhancing damage resistance of functional surface

A technology of enhanced function and micro-nano mechanics, applied in the direction of microstructure technology, microstructure devices composed of deformable elements, microstructure devices, etc., can solve problems such as large local pressure, stress concentration, and structural collapse, and achieve reduction Stress, improve stress distribution, improve the effect of damage tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

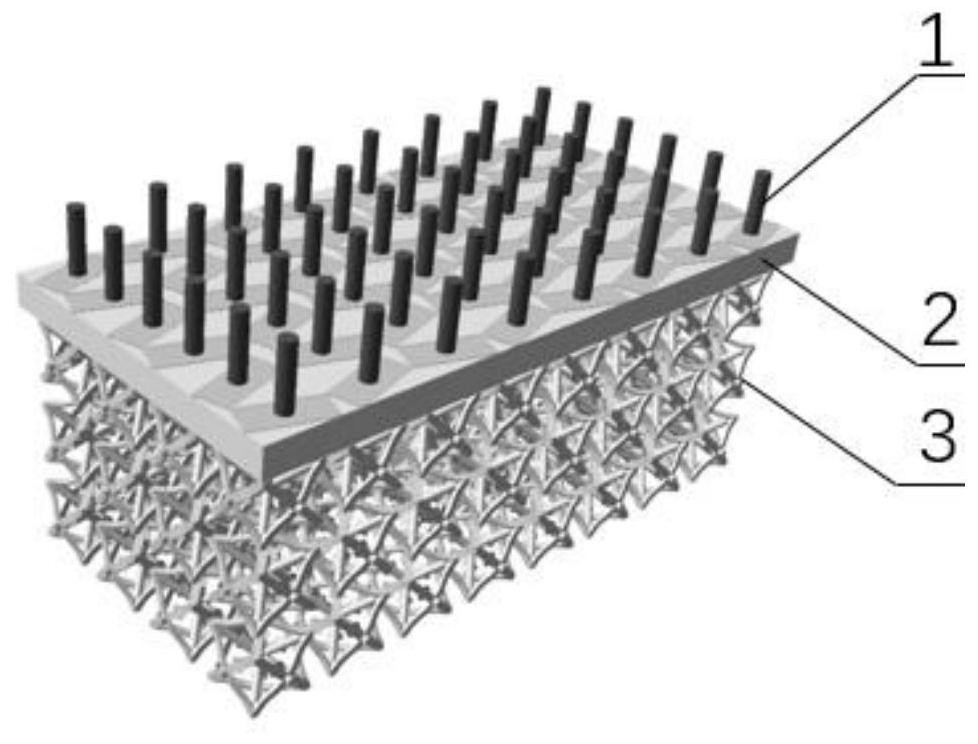

[0034] Embodiment 1, with reference to figure 1 , a multi-level micro-nano mechanical structure for enhancing the damage resistance of functional surfaces, comprising a micro-nano composite structure functional layer 1, an interconnected network structure functional layer 2, and a mechanical artificial structure functional layer 3;

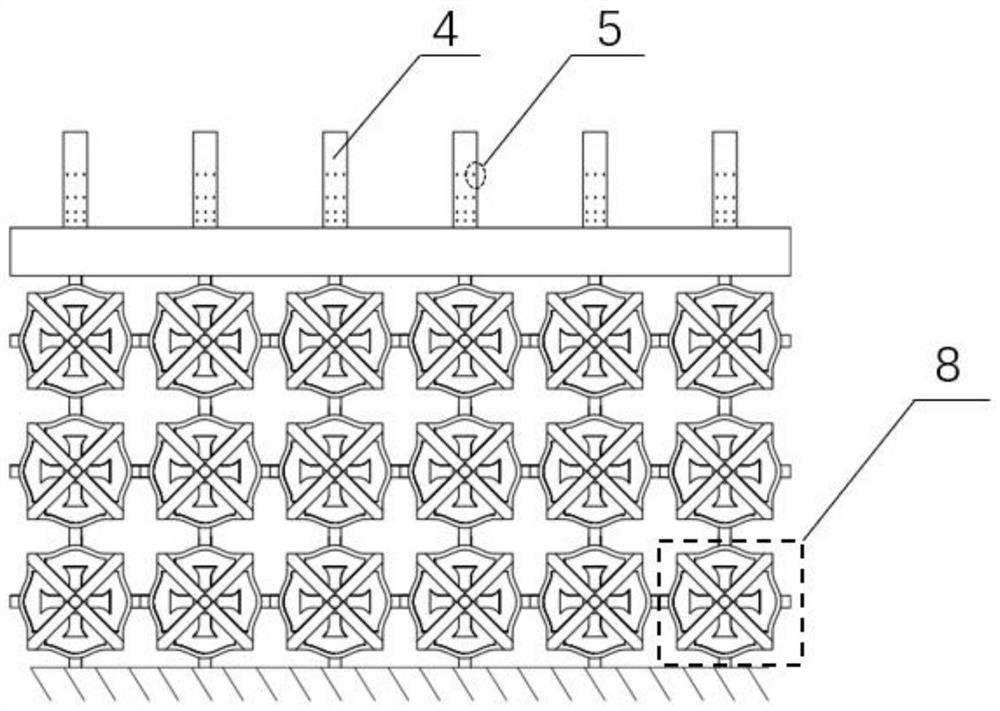

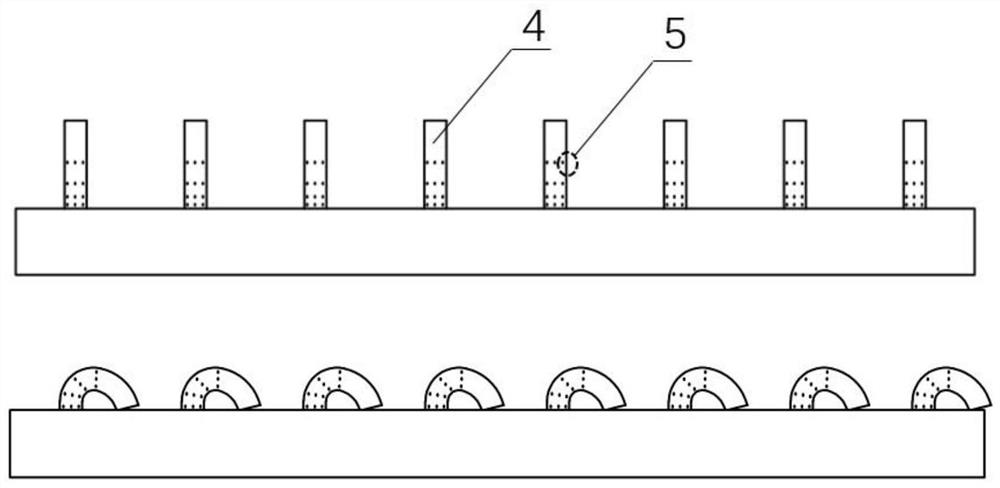

[0035] refer to figure 2 , the micro-nano composite structure functional layer 1 is a micro-column array structure that exerts surface functions; in order to achieve a certain surface function, it is necessary to design a specific micro-column 4 array on the surface, and the micro-column 4 array is a uniform array of micro-columns. The diameter of the cylinder is 0.5-50μm;

[0036] refer to image 3 , through the bulk phase distribution technology of nanoparticles, the asymmetric part of the nanoparticles 5 is distributed on the upper and lower sides of the microcolumn 4, so that the concentration at the bottom is high. Change the internal str...

Embodiment 2

[0041] Embodiment 2, with reference to Figure 6 , a multi-level micro-nano mechanical structure for enhancing the damage resistance of functional surfaces, comprising a micro-nano composite structure functional layer 1, an interconnected network structure functional layer 2, and a mechanical artificial structure functional layer 3;

[0042] refer to Figure 7 , the micro-nano composite structure functional layer 1 is a micro-column array structure that exerts surface functions; in order to achieve a certain surface function, it is necessary to design a specific micro-column 4 array on the surface, the micro-column array is a uniform array of micro-columns, and the micro-columns The diameter is 0.5 ~ 100μm;

[0043] The magnetic nanoparticles 5 are asymmetrically distributed on the upper and lower sides of the microcolumn 4 through the nanoparticle bulk phase distribution technology, so that the concentration at the bottom is high. Change the internal stress state to avoid f...

Embodiment 3

[0048] Embodiment 3, with reference to Figure 9 , this embodiment is an improvement to Embodiment 2. The mechanical artificial structure functional layer 3 is composed of an active artificial lattice 10, and its material includes a shape memory polymer (SMP) and a responsive hydrogel. After applying an external field The change of the structure of the active artificial lattice 10 can be realized, resulting in the transformation of the mechanical properties of the active artificial lattice 10, and then the reconstruction of the functional layer 3 of the mechanical artificial structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com