High-liquid-absorption-rate porous ceramic matrix and heating element

A technology of porous ceramics and high liquid absorption rate, which is applied in the field of porous ceramics. It can solve the problems that the porous ceramic substrate has a larger porosity than the liquid absorption rate, limits the application field of porous ceramic atomizers, and has insufficient oil locking function, so as to achieve convenient smoking. Oil penetration, facilitate the penetration of e-liquid, and enhance the experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A high suction rate porous ceramic matrix comprising a weight of the weight:

[0033]

[0034] The porous silica microspheres have a particle diameter of 0.5 μm; the porous silica microsphereshell micropores have a pore diameter of 0.2 μm.

[0035] The pore agent is a mixture of PMMA, graphite, polystyrene, and oleic acid according to a weight ratio of 0.4: 0.6: 0.1: 0.8.

[0036] The porous ceramic base 1 has a porosity of 40% and a suction rate of 60%; a gap size between the porous ceramic base 1 inner particles is 0.5 μm, and the porous ceramic matrix 1 is volatilized. The post-pore diameter is 2 μm.

[0037] The porous ceramic substrate 1 is molded by thermocompression molding or injection molding; the porous ceramic substrate 1 is sintered under 600 ° C.

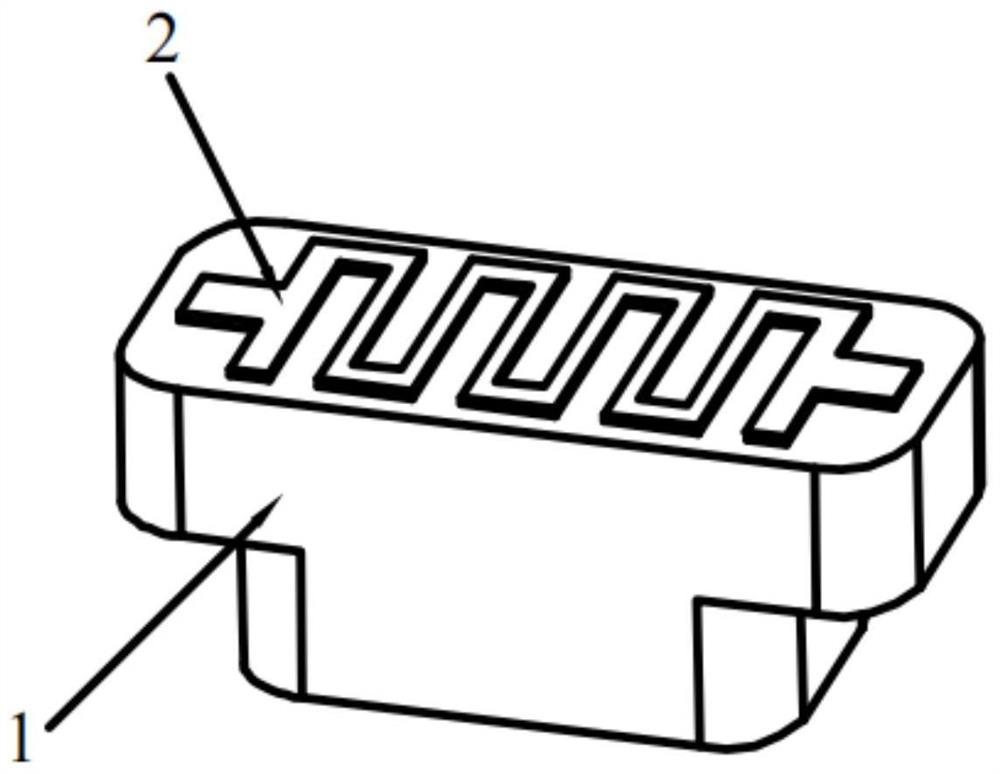

[0038] A high-absorbing rate of heat generating body comprising the above-mentioned porous ceramic substrate 1, and a metal heating sheet 2 disposed on the lower surface of the porous ceramic substrate 1.

Embodiment 2

[0040] A high suction rate porous ceramic matrix comprising a weight of the weight:

[0041]

[0042]

[0043] The porous silica microspheres have a particle diameter of 5 μm; the porous silica microsphereshell micropores have a pore diameter of 0.5 μm.

[0044] The aperture agent is a mixture of PMMA, graphite, polystyrene, and oleic acid according to a weight ratio of 0.5: 0.7: 0.2: 0.9.

[0045] The porous ceramic substrate 1 has a porosity of 48% and a suction rate of 65%; a gap size between the porous ceramic substrate 1 inner particles is 5 μm, and the porous ceramic matrix 1 is volatilized. The aperture is 8 μm.

[0046]The porous ceramic substrate by using a hot die casting or injection molding; 1 the porous ceramic matrix sintered at 750 ℃,.

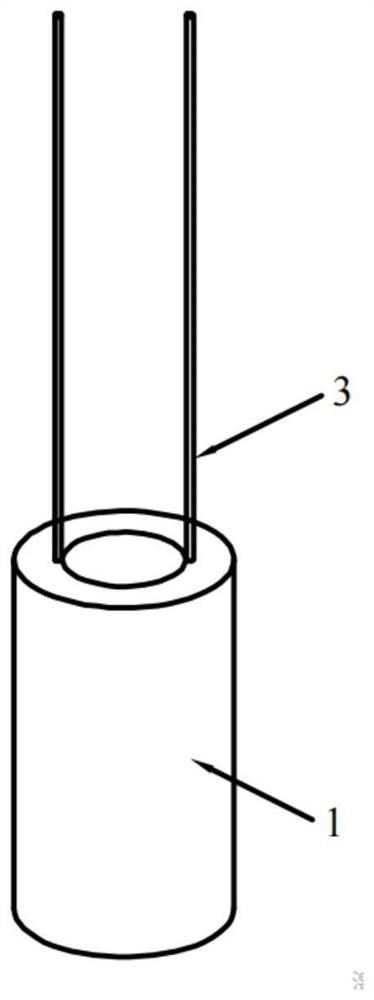

[0047] A high-heat generating body fluid absorbent rate, including 1, 1 and provided inside or outside of the porous ceramic body a helical heating wire 3 the porous ceramic matrix.

Embodiment 3

[0049] A high-rate liquid-absorbent porous ceramic matrix, comprising the following parts by weight of the starting material:

[0050]

[0051] The particle diameter of porous silica microspheres of 7 m; the porous silica microspheres own pore size of micropores 1μm.

[0052] The ratio of the pore forming agent is PMMA, graphite, polystyrene, and oleic acid in a weight of 0.6: 0.8: 0.3: 1.0 mixture composed.

[0053] A porosity of 55% of the porous ceramic matrix, the pipetting 70%; 1 inside the particle accumulation between the porous ceramic matrix gap size is 7 m, in the porous ceramic substrate 1 after pore-forming agent volatilized the pore size of 13μm.

[0054] The porous ceramic substrate by using a hot die casting or injection molding; the porous sintered ceramic substrate 1 at 900 deg.] C of.

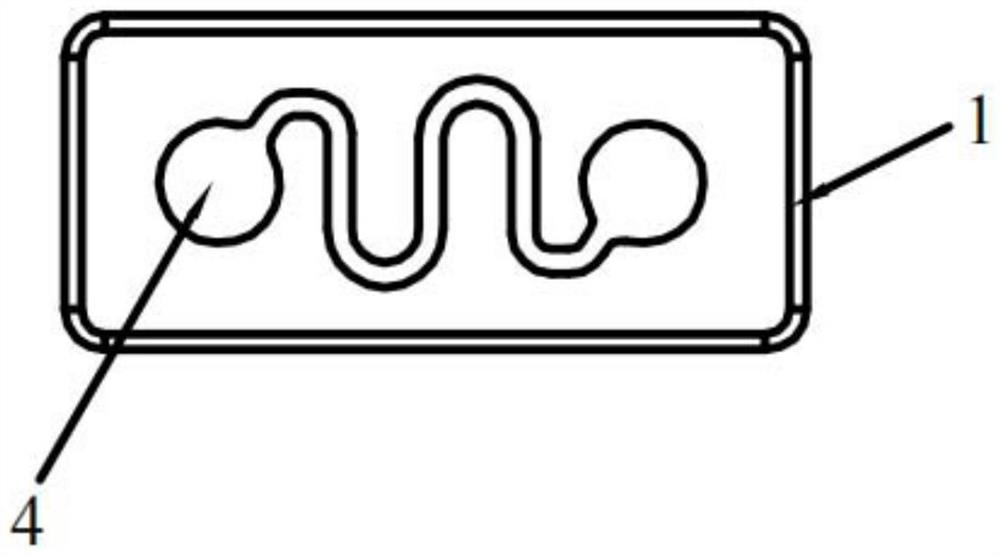

[0055] A high-absorption rate of the liquid heat generator, comprising the porous ceramic base body 1, and printed on the surface of a porous ceramic substrate 4 fever line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Gap size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com