Preparation method of ZrB2-ZrC-SiC nano composite ceramic material

A nano-composite, ceramic material technology is applied in the field of ceramic matrix composite material preparation, and achieves the effects of good application prospect, good mechanical and ablation resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

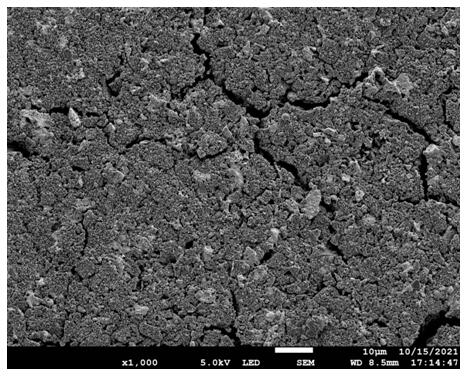

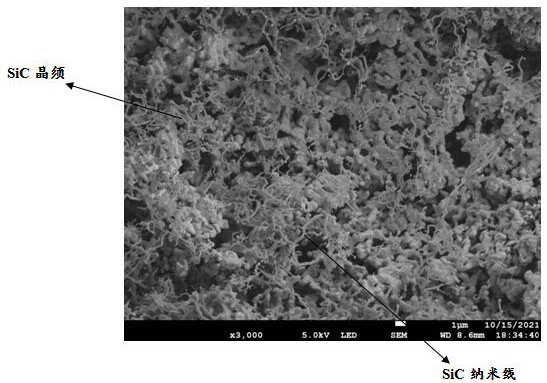

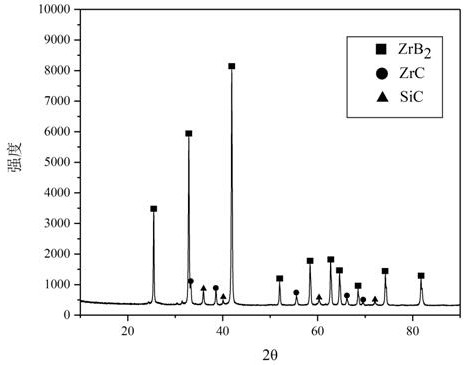

Image

Examples

Embodiment 1

[0035] a ZrB 2 -The preparation method of ZrC-SiC nano-composite ceramic material, comprises the following steps:

[0036] Configuration of zirconium precursor solution: Weigh 3.2g of zirconium oxychloride for later use, dissolve zirconium oxychloride in 30mL of absolute ethanol, add 6.8g of 30% H 2 o 2 and 0.3g PEG6000, stirred evenly in a water bath at 65°C to obtain a zirconium precursor solution;

[0037] Configuration of the silicon precursor solution: according to the molar ratio of zirconium oxychloride to ethyl orthosilicate 1:0.7, weigh 1.5g of ethyl orthosilicate and dissolve it in 20mL of absolute ethanol, and stir evenly to obtain the silicon precursor solution;

[0038] Preparation of boron precursor solution: According to the molar ratio of zirconium oxychloride and boric acid as 1:2.5, weigh 1.55g of boric acid and dissolve it in 30mL of absolute ethanol, and stir evenly in a water bath at 50°C to obtain a boron precursor solution;

[0039] Preparation of car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com