Degradable high-heat-resistance jelly glue and preparation method thereof

A jelly glue, high heat-resistant technology, applied in the preparation of animal glue or gelatin, adhesives, adhesive types, etc., can solve problems such as general bonding strength, difficulty in meeting the packaging requirements of high-end paper products, and poor heat resistance , to achieve the effect of improving the initial adhesive force, improving the degradability, improving the bonding strength and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

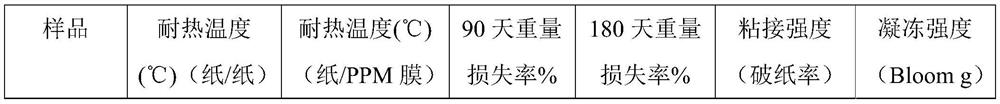

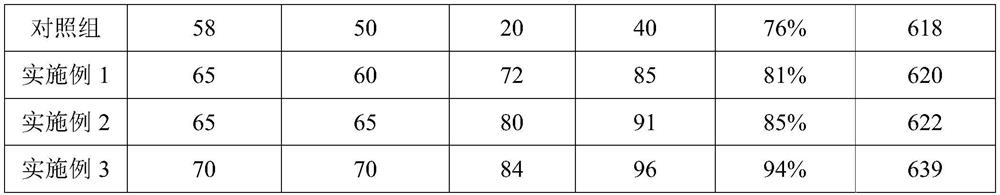

Examples

Embodiment 1

[0018] The present invention provides a novel degradable high heat-resistant jelly glue, which is obtained by the following method:

[0019] Weigh 14 parts by weight of deionized water, add 24 parts by weight of industrial gelatin with a freezing strength of 180 Bloom g, add the deionized water and industrial gelatin into the kettle to dissolve and raise the temperature to 68-72°C for 1.5h-2h, and then dissolve it completely Add 0.1 parts by weight of Digo 800 mineral oil defoamer, 0.1 parts by weight of Rocima BTNV2 preservative and 0.1 parts by weight of sodium bisulfite, keep warm for 0.5h to 1h, then slowly add 10 parts by weight of magnesium sulfate heptahydrate, Keep warm for 0.5h to 1h, and slowly add 15 parts by weight of polylactic acid solution dropwise. The polylactic acid solution includes the following raw materials in units of weight: 50 parts of polylactic acid resin, 10 parts of 0.03mol / L sodium hydroxide solution, co-solvent 2 parts, 38 parts of deionized wate...

Embodiment 2

[0022] Weigh 20 parts by weight of deionized water, add 22 parts by weight of industrial gelatin with a freezing strength of 180 Bloom g, add the deionized water and industrial gelatin into the kettle to dissolve and heat up to 68-72°C for 1.5h-2h, and then dissolve them completely Add 0.1 parts by weight of Digo 800 mineral oil defoamer, 0.1 parts by weight of Rocima BTNV2 preservative, 0.05 parts by weight of sodium dithionite and 0.1 parts by weight of sodium bisulfite, keep warm for 0.5h to 1h, and then slowly add 10 Magnesium sulfate heptahydrate by weight, keep warm for 0.5h-1h, slowly add 19 parts by weight of polylactic acid solution dropwise, the polylactic acid solution includes the following raw materials in units of weight: 50 parts of polylactic acid resin, 0.03mol / L hydrogenated 10 parts of sodium solution, 2 parts of co-solvent, 38 parts of deionized water, the polylactic acid resin includes but not limited to SYNTERRA PLLA 2011, heat preservation for 1h to 2h, a...

Embodiment 3

[0025] Weigh 15 parts by weight of deionized water, add 25 parts by weight of industrial gelatin with a freezing strength of 180 Bloom g, add the deionized water and industrial gelatin into the kettle to dissolve and raise the temperature to 68-72°C for 1.5h-2h, and then dissolve it completely Add 0.2 parts by weight of Digo 800 mineral oil defoamer, 0.2 parts by weight of Rocima BTNV2 preservative, 0.1 parts by weight of sodium dithionite and 0.2 parts by weight of sodium bisulfite, keep warm for 0.5h to 1h, and then slowly add 8 Magnesium sulfate heptahydrate by weight, keep warm for 0.5h~1h, slowly add 25 parts by weight of polylactic acid solution dropwise, and the polylactic acid solution includes the following raw materials in units of weight: 50 parts of polylactic acid resin, 0.03mol / L hydroxide 10 parts of sodium solution, 2 parts of co-solvent, 38 parts of deionized water, the polylactic acid resin includes but not limited to SYNTERRA PLLA 2011, heat preservation for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com