System and method for testing alkali metal atom number density spatial distribution uniformity of atom magnetometer

A technology of atomic magnetic intensity and spatial distribution, which is applied to the size/direction of the magnetic field, the use of magneto-optical equipment for magnetic field measurement, measurement devices, etc. Uneven distribution and other problems, to achieve the effect of suppressing common mode interference, easy implementation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through the accompanying drawings and specific embodiments.

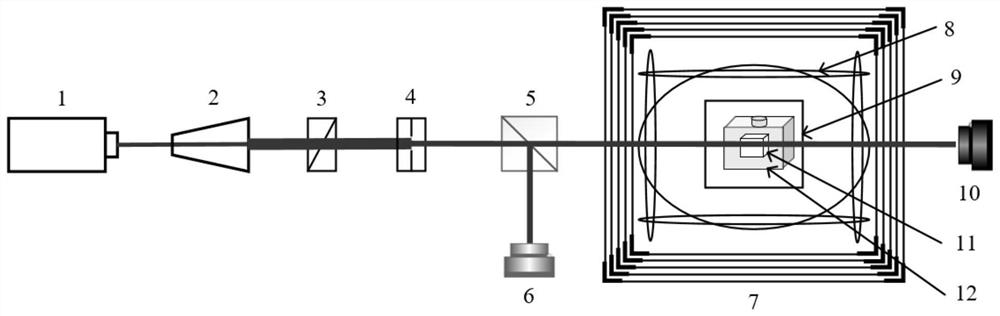

[0022] Such as figure 1 As shown, the present invention proposes a test system for the uniformity of the spatial distribution of the alkali metal atomic number density of an atomic magnetometer, including a detection light laser 1, a laser beam expander 2, and a polarizer 3 arranged in sequence according to the direction in which the detection light advances , diaphragm 4, beam splitting prism 5, alkali metal atom gas chamber 11, first beam profile camera 10, described alkali metal atom gas chamber 11 is coated with oven 12, vacuum cavity 9, magnetic compensation coil in sequence from inside to outside 8. Magnetic shielding system 7; the beam splitting prism 5 divides the detection light into two beams of refracted light, one beam of refracted light enters the first beam profile camera 10 after passing through the alkali metal atom gas chamber 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com