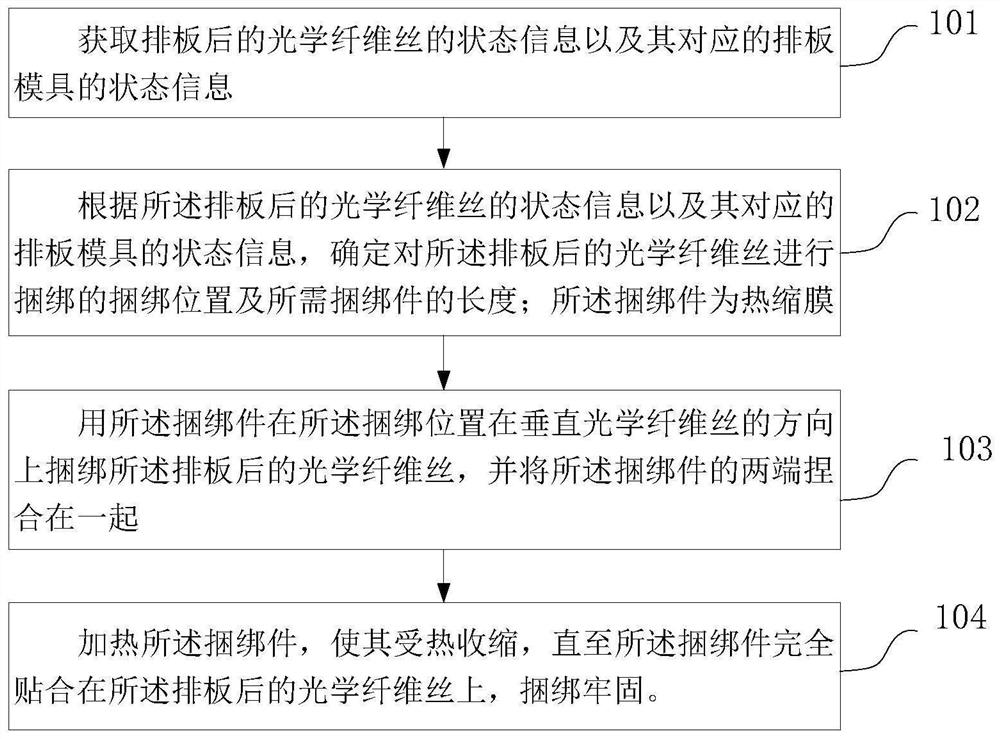

Method and device for binding arranged optical fiber filaments

An optical fiber and board-behind technology, applied in the direction of bundled optical fibers, etc., can solve the problems such as the sliding and loosening of the optical fiber filament board structure, the unstable internal structure of the optical fiber panel product, and the failure of the optical fiber imaging element to be used normally. Stabilize, improve product quality and product quality stability, and reduce the effect of production losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] In some embodiments, the preparation method of the cage-type oligomeric silsesquioxane-modified silica gel membrane composite heat-shrinkable silica gel membrane comprises the following steps:

[0061] Under stirring conditions, add cage-type oligomeric silsesquioxane and thermally conductive fillers to vinyl silicone rubber in turn, mix well, press to form a film, and then cure at 40°C to 60°C for 2 to 6 hours. A cage-type oligomeric silsesquioxane modified silica gel membrane was obtained. Wherein, in parts by weight, there are 80-100 parts of vinyl silicone rubber, 10-18 parts of cage-type oligomeric silsesquioxane and 5-10 parts of thermally conductive filler.

[0062] Further, the preparation method of cage oligomeric silsesquioxane comprises the following steps:

[0063] in N 2 Under gas protection, add 25g of ferric chloride and 10mL of concentrated hydrochloric acid into the three-necked flask, then add 20mL of methanol, 25mL of toluene and 150mL of n-hexane i...

Embodiment 1

[0093] A preparation method of a cage-type oligomeric silsesquioxane modified silica gel membrane, comprising the following steps:

[0094]Under the action of an electric stirrer, the raw materials were weighed according to the formula amount of Example 1 in Table 1, and the cage-type oligomeric silsesquioxane and boron nitride were added to the vinyl silicone rubber in turn, mixed evenly, and reacted for 2.5 After one hour, a calender was used to form a film, and then cured at 50° C. for 3 hours to obtain a cage-type oligomeric silsesquioxane-modified silica gel heat-shrinkable film.

[0095] After testing, the properties of the cage-type oligomeric silsesquioxane-modified silica gel heat-shrinkable film obtained in Example 1 are listed in Table 1.

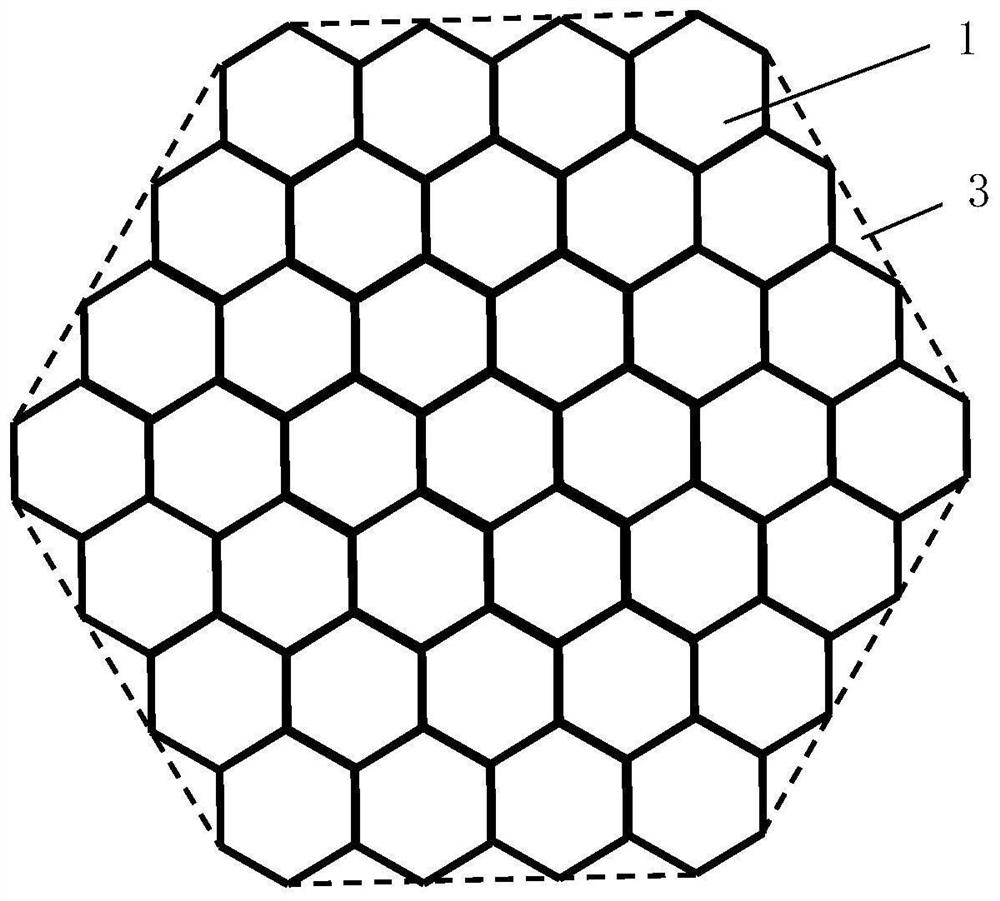

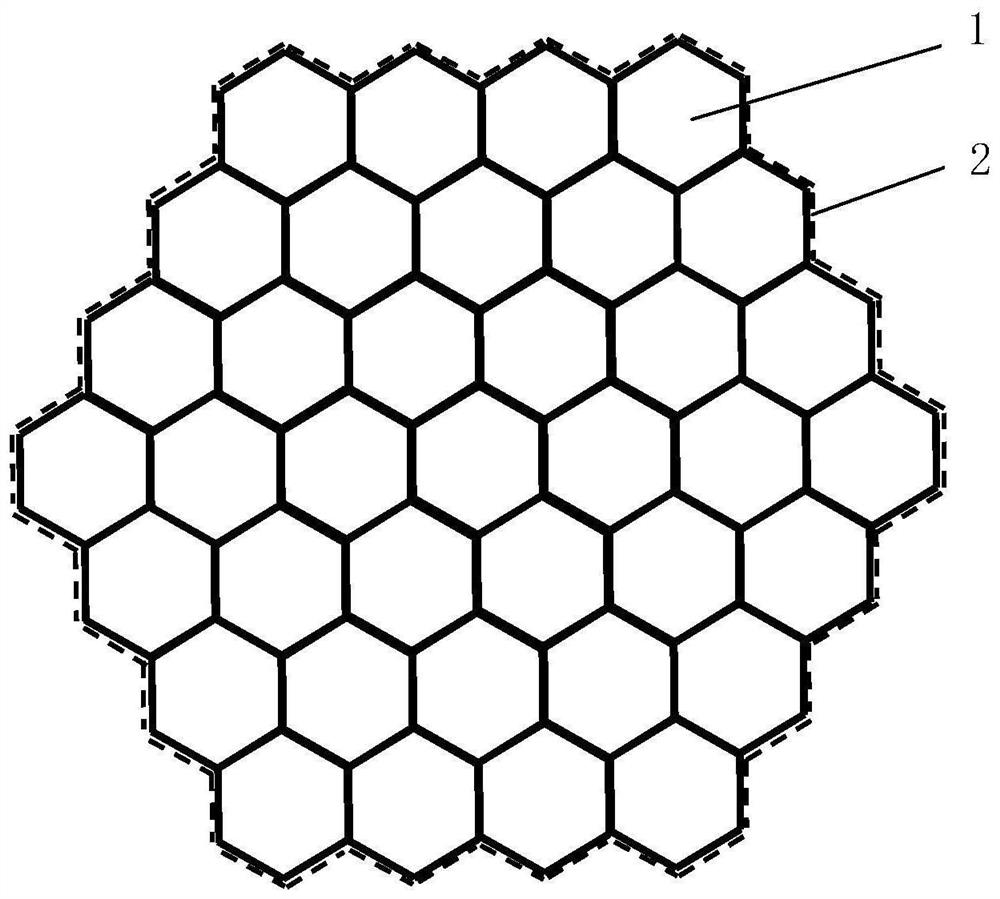

[0096] by image 3 37 optical fiber filaments are arranged in the arrangement shown, the length of the optical fiber filaments is 100 mm, and the circumference of the cross section is 24.2 mm. The silica gel heat-shrinkable film...

Embodiment 2

[0099] The preparation method of embodiment 2 is the same as that of embodiment 1, except that the proportioning of raw materials is different, and the raw materials are weighed according to the formula amount of embodiment 2 in table 1.

[0100] After testing, the properties of the cage-type oligomeric silsesquioxane-modified silica gel heat-shrinkable film obtained in Example 2 are listed in Table 1.

[0101] according to image 3 Arranged in the manner shown, using the cage-type oligomeric silsesquioxane-modified silica gel heat-shrinkable film obtained in Example 2 to bind 37 optical fiber filaments, and to test the inclination angle to test the silica gel heat-shrinkable film Stability of the bundled optical fiber wire arrangement structure: when the inclination angle is 60°, the number of optical fiber wires sliding out from the optical fiber base plate is 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com