Manufacturing method and detection method of thin film packaging Test key

A technology of thin film encapsulation and manufacturing method, applied in the field of OLED displays, can solve the problems of low brightness, easy failure of encapsulation structure, short life of OLED displays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

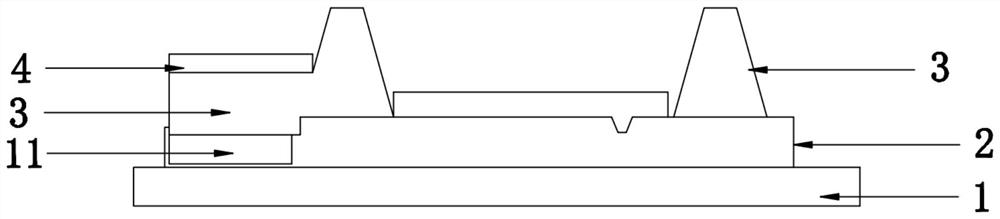

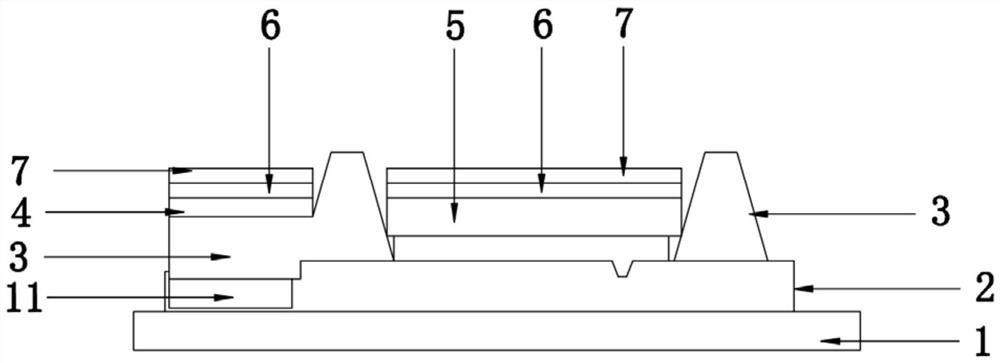

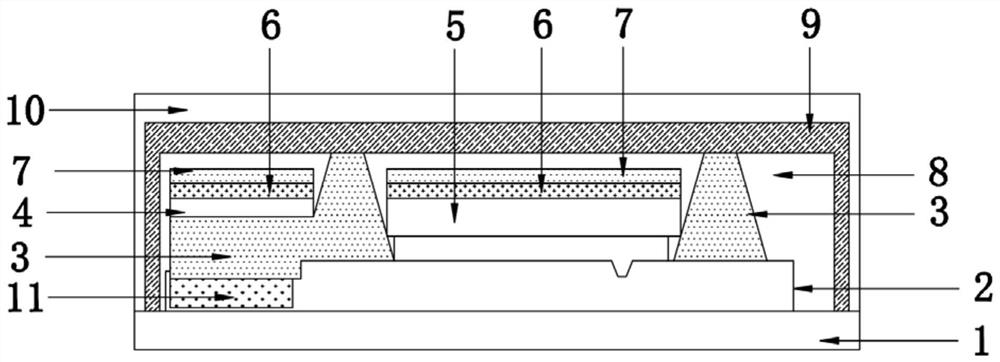

[0036] A method for detecting a thin-film packaged test key is applied to a film-packaged test key structure prepared by a method for producing a thin-film packaged test key. A water-oxygen detection test key structure of the invention includes Figure 4 The anode 4, the cathode (i.e. the Mg cathode 6 and the Ag cathode 7), the thin-film encapsulation layer (i.e. the first water-oxygen barrier layer 8, the organic buffer layer 9 and the second water-oxygen barrier layer 10), such as Figure 4 , where B represents the direction of water and oxygen intrusion;

[0037] The detection method is to detect the change in the transmittance of the test key by testing water and oxygen, and feedback the degree of water and oxygen intrusion. When water and oxygen penetrate into the anode 4 and cathode from the gap in the film packaging layer, since the anode 4 is made of ITO / Ag / ITO composition, when water and oxygen enter, Ag is easily oxidized into silver oxide by water and oxygen, and t...

Embodiment 2

[0039] A method for detecting a thin-film packaged test key is applied to a film-packaged test key structure prepared by a method for producing a thin-film packaged test key. A water-oxygen detection test key structure of the invention includes Figure 4 The anode 4, the cathode (i.e. the Mg cathode 6 and the Ag cathode 7), the thin film encapsulation layer (i.e. the first water-oxygen barrier layer 8, the organic buffer layer 9 and the second water-oxygen barrier layer 10), the detection method is through Test the resistance value change of the water and oxygen detection test key, and feedback the degree of water and oxygen intrusion. When water and oxygen penetrate into the anode 4 and the cathode from the gap in the film encapsulation layer, since the anode 4 is composed of ITO / Ag / ITO, when water After oxygen enters, Ag is easily oxidized by water and oxygen into silver oxide, in which the resistance of silver oxide and metal silver is different, and the laminated layer of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com