PECVD process for reducing EL winding plating smudginess of crystalline silicon solar cell

A solar cell and process technology, applied in the field of PECVD process, can solve the problems of no PECVD process process optimization, the final effect is not obvious, etc., to achieve the effect of reducing EL winding and plating dirt, no need for equipment investment, and lower process temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

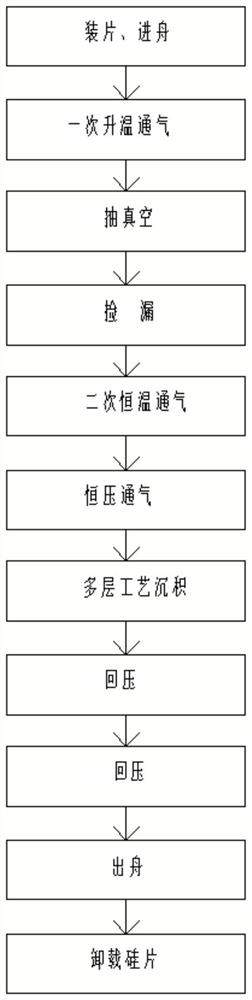

Image

Examples

Embodiment 1

[0034] A PECVD process for reducing EL coating contamination of crystalline silicon solar cells, the experimental group includes the following steps:

[0035] Step 1: Automatically load the silicon wafers after the back coating into the graphite boat in the front coating process;

[0036] Step 2: Enter the boat to open the furnace door, automatically transport the graphite boat full of silicon wafers to be processed into the process furnace tube, and close the furnace door. The speed of entering the boat is 3500cm / min, and the step time is 80s.

[0037] Step 3: The constant temperature furnace tube has a heating and temperature control system, which will automatically heat up to the process setting temperature: the furnace mouth is 530°C, and the furnace tail is 480°C. The reaction needs to be carried out under constant temperature conditions, and the time is 400s, so that the temperature in the reaction chamber reaches and Constantly set the temperature: 530°C at the furnace...

Embodiment 2

[0049] Embodiment 2: A kind of PECVD process that reduces crystalline silicon solar cell EL wraps around plating dirty, contrast group comprises the following steps:

[0050] Step 1: Automatically load the silicon wafers after the back coating into the graphite boat in the front coating process;

[0051] Step 2: Enter the boat to open the furnace door, automatically transport the graphite boat full of silicon wafers to be processed into the process furnace tube, and close the furnace door. The speed of entering the boat is 3500cm / min, and the step time is 80s.

[0052] Step 3: The constant temperature reaction needs to be carried out under constant temperature conditions, and the time is 350s, so that the temperature in the reaction chamber is kept constant at the set temperature: the furnace mouth is 560°C, and the furnace tail is 500°C.

[0053] Step 4: Vacuumize the furnace tube to achieve the vacuum conditions required for the film deposition reaction. At the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com