Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as affecting device efficiency, corroding metal cells, reducing device efficiency, etc., and achieving the effect of improving device stability and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

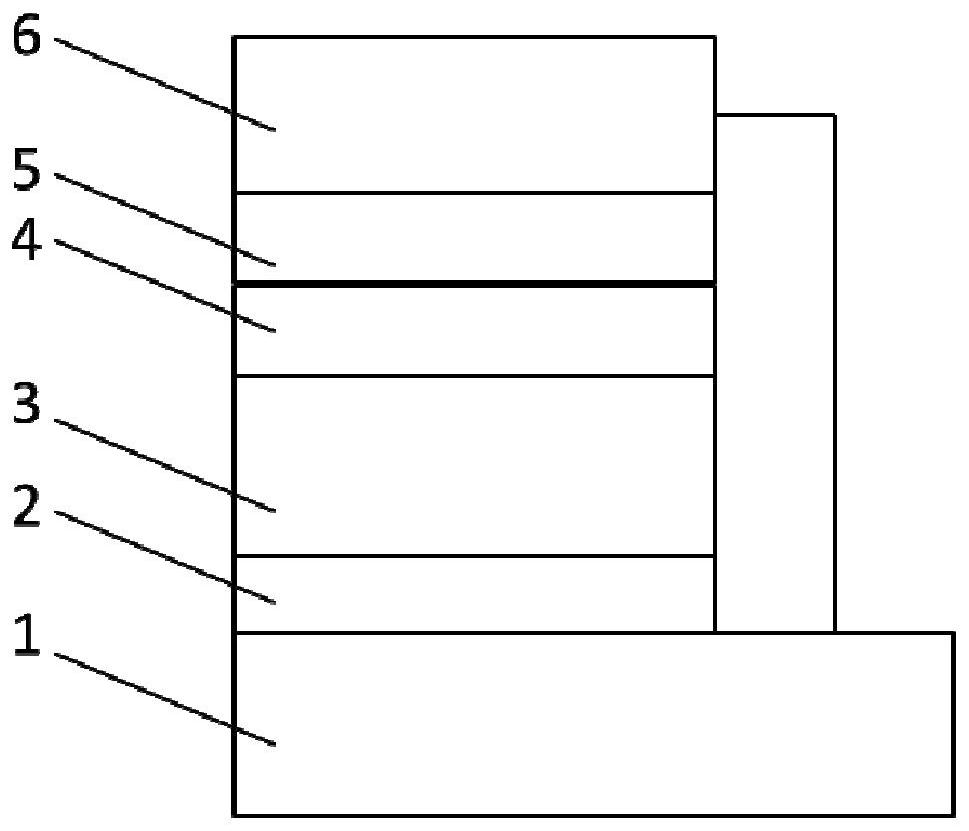

[0045] refer to figure 1 , The perovskite solar cell of this embodiment comprises a substrate 1, a hole transport layer 2, a perovskite film 3, a sulfide layer 4, an electron transport layer 5 and an electrode 6 which are sequentially stacked, and the preparation process is as follows:

[0046] Using ITO conductive glass as the substrate 1, first wash with ITO cleaning agent and deionized water to remove grease and organic matter, then ultrasonically wash with deionized water, acetone, and isopropanol in sequence, blow dry with nitrogen, and then clean with ozone plasma further processing.

[0047] The hole transport layer 2 was fabricated on the treated ITO conductive glass by spin coating. The hole transport layer 2 is a P3CT-N material layer, which is formed by spin-coating a methanol solution of P3CT-N with a concentration of 1 mg / mL. The speed of the homogenizer is 4000 rpm, the time is 45 seconds, and the thickness is 10 nm.

[0048] Fabricate a perovskite film 3 on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap