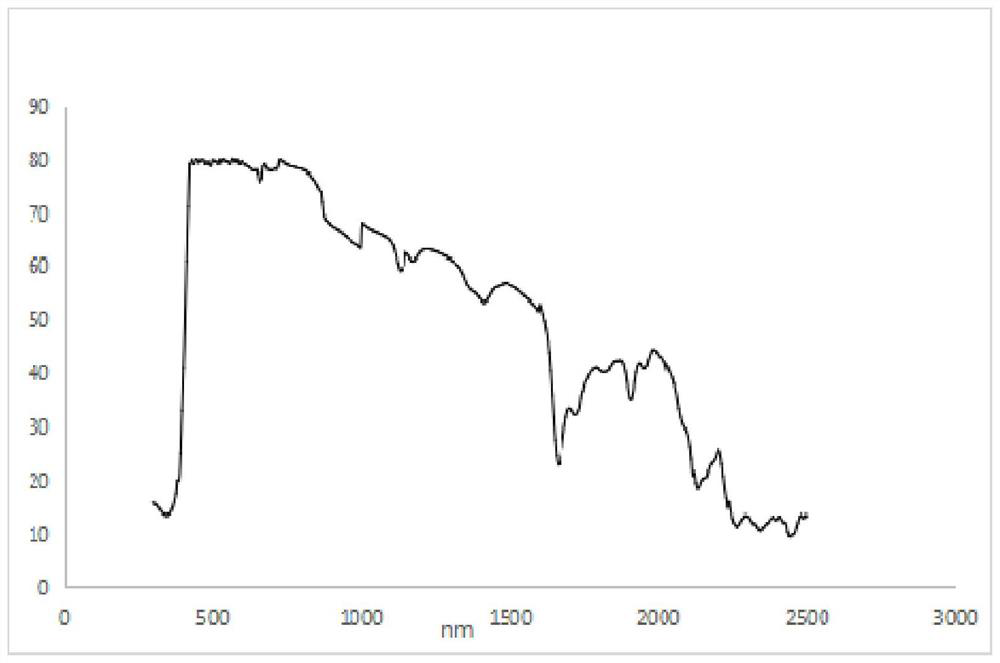

Infrared reflection alpha-PbO2 phase titanium dioxide-zirconium oxide nano composite material and preparation method thereof

A nano-composite material, titanium dioxide technology, applied in the directions of titanium oxide/hydroxide, titanium dioxide, zirconium oxide, etc., can solve the problems of complex preparation method, high cost, uneven doping, etc., and achieves simple and feasible process route. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] S1. Weigh 8gα-PbO 2 Phase titanium dioxide powder is added to 50ml of deionized water, and under 40KHz ultrasonic wave, disperse at a high speed of 500rpm for 15 minutes to obtain activated α-PbO 2 phase titanium dioxide powder suspension;

[0032] S2, take by weighing 36.7g zirconium acetate, be dissolved in 400ml ionic water solution, and stir evenly;

[0033] S3, adding S1-activated α-PbO to the S2 solution 2 Phase titanium dioxide powder suspension, keep stirring in the whole process, the speed of stirring is 400rpm, and the time is 30 minutes;

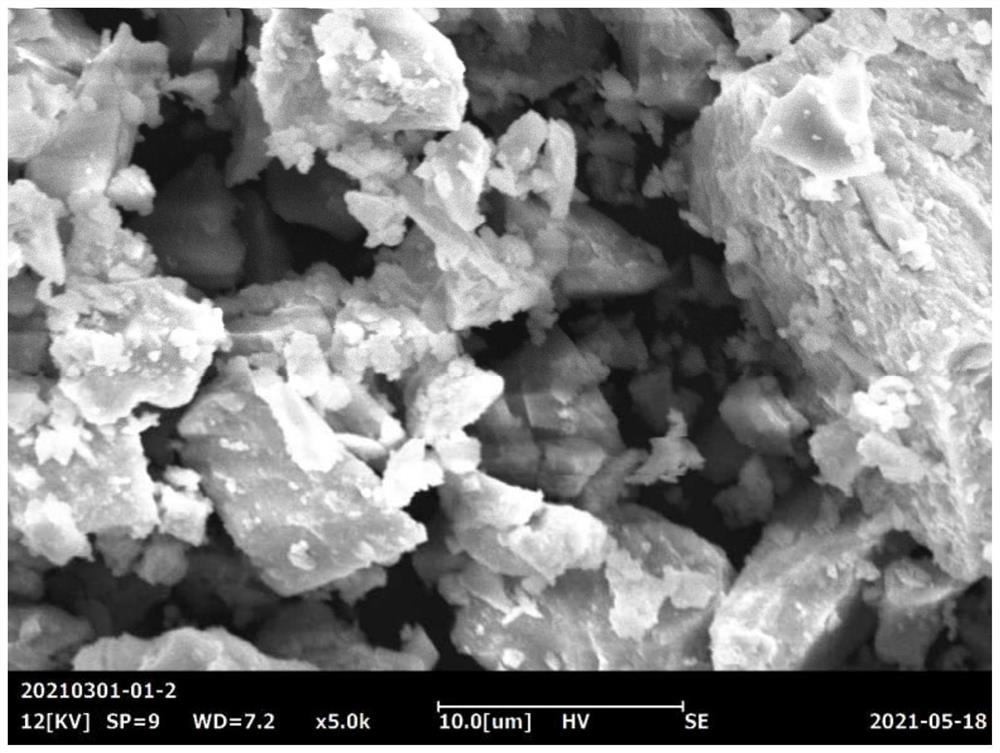

[0034] S4. Put the above-mentioned mixed solution into the delivery device, pump it into the supercritical pure fluid for reaction through the device, generate zirconia crystals and coat the surface of titanium dioxide, form microspheres with a core-shell structure, and improve α -PbO 2 The infrared reflection efficiency of phase titanium dioxide, the supercritical reaction temperature is 120 ° C, the pressure is 23 MPA...

Embodiment 2

[0037] S1. Weigh 8gα-PbO 2 Phase titanium dioxide powder is added to 50ml of deionized water, and under 40KHz ultrasonic wave, disperse at a high speed of 500rpm for 15 minutes to obtain activated α-PbO 2 phase titanium dioxide powder suspension;

[0038] S2, take by weighing 32.3g zirconium sulfate, be dissolved in 300ml ion aqueous solution, and stir evenly;

[0039] S3, adding S1-activated α-PbO to the solution in step S2 2 Phase titanium dioxide powder, keep stirring in the whole process, the speed of stirring is 400rpm, and the time is 30 minutes;

[0040] S4. Put the above-mentioned mixed solution into the delivery device, pump it into the supercritical pure fluid for reaction, generate zirconia crystals and coat the surface of titanium dioxide, form microspheres with a core-shell structure, and increase the concentration of α-PbO 2 The infrared reflection efficiency of phase titanium dioxide, the supercritical reaction temperature is 140°C, the pressure is 24MPA, and...

Embodiment 3

[0043] S1. Weigh 8gα-PbO2 Phase titanium dioxide powder is added to 50ml of deionized water, and under 40KHz ultrasonic wave, disperse at a high speed of 500rpm for 15 minutes to obtain activated α-PbO 2 phase titanium dioxide powder suspension;

[0044] S2, take by weighing 37.9g zirconium nitrate, be dissolved in 400ml ion aqueous solution, and stir;

[0045] S3, adding S1-activated α-PbO to the solution in step S2 2 Phase titanium dioxide powder, keep stirring in the whole process, the speed of stirring is 400rpm, and the time is 30 minutes;

[0046] S4. Put the above-mentioned mixed solution into the delivery device, pump it into the supercritical pure fluid for reaction, generate zirconia crystals and coat the surface of titanium dioxide, form microspheres with core-shell structure, and increase the concentration of α-PbO 2 The infrared reflection efficiency of phase titanium dioxide, the supercritical reaction temperature is 160°C, the pressure is 25MPA, and the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com