High-salt nitrogen-containing organic wastewater recycling and safe discharging integrated equipment

A technology for organic wastewater and safe discharge, applied in water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as unstable operation, high investment and operating costs, and lack of enhanced conversion and removal of organic nitrogen , to achieve the effect of stable operation and improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

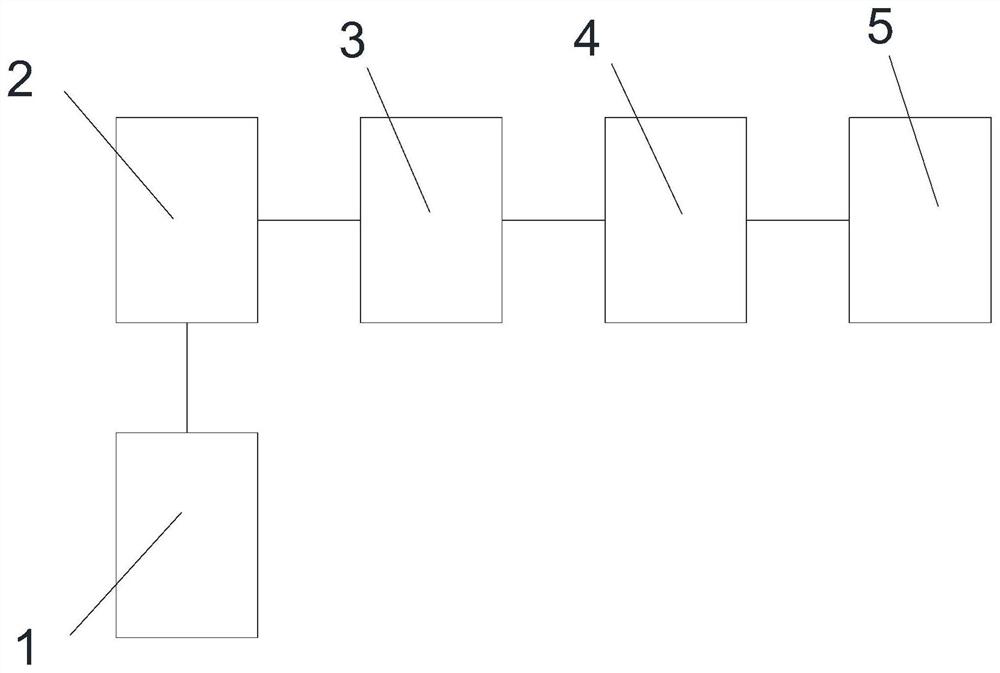

[0069] The embodiment of the present invention provides an integrated equipment for resource utilization and safe discharge of high-salt nitrogen-containing organic wastewater, such as Figure 1-Figure 8 As shown, it includes: a photocatalytic oxidation device 1, the input end of the photocatalytic oxidation device 1 is provided with an evaporation crystallization device 2, and the output end of the evaporation crystallization device 2 is also provided with a biochemical treatment device 3, and the biochemical treatment device 3 The output end is provided with a microbubble catalytic ozonation device 4, and the output end of the microbubble catalytic ozonation device 4 is provided with a pre-denitrification graded biological denitrification device 5.

[0070] The working principle and beneficial effects of the above technical solution are as follows: in the present invention, the high-salt nitrogen-containing organic waste water is evaporated and crystallized through the evapor...

Embodiment 2

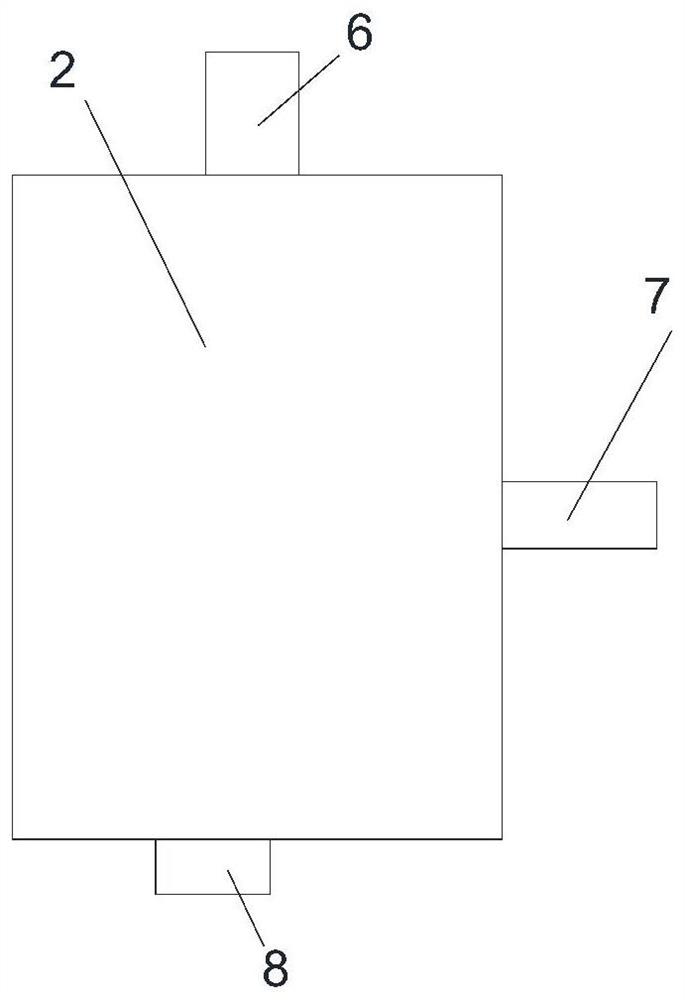

[0072] On the basis of above-mentioned embodiment 1, as Figure 1-Figure 5 As shown, the evaporation and crystallization device 2 is provided with a first waste water inflow pipe 6, a first waste water outflow pipe 7 and a crystal outlet 8;

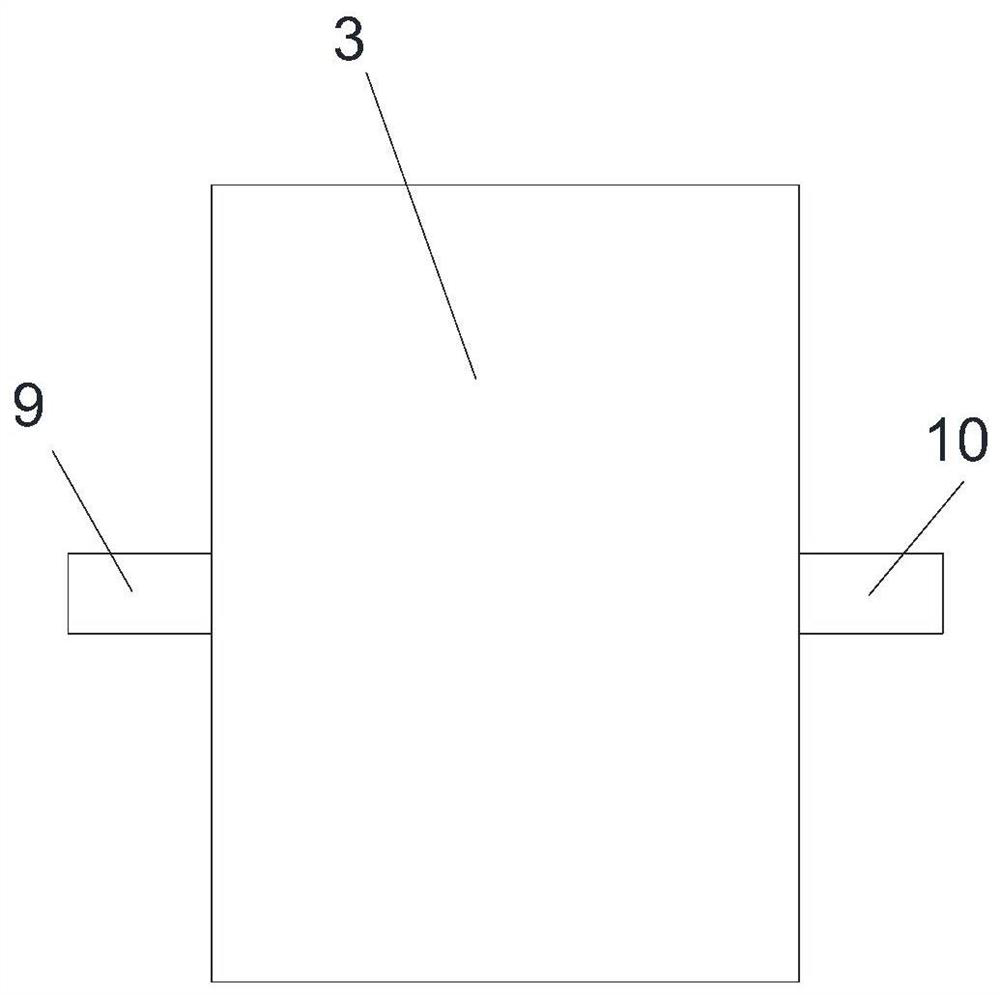

[0073] The inside of the biochemical treatment device 3 is provided with microorganisms, the biochemical treatment device 3 is provided with a second waste water inflow pipe 9 and a second waste water outflow pipe 10, and the second waste water inflow pipe 9 is connected with the first waste water outflow pipe 7 ;

[0074] The microbubble catalytic ozonation device 4 is provided with a third waste water inflow pipe 11 and a third waste water outflow pipe 12, one end of the third waste water inflow pipe 11 is connected with the second waste water outflow pipe 10, and the third waste water flows into The other end of the pipe 11 extends to the inside of the microbubble catalytic ozonation device 4 to communicate, the third waste water infl...

Embodiment 3

[0098] On the basis of Example 2, such as Figure 5 , Figure 6 As shown, the fourth waste water inflow pipe 22 is provided with a carbon source addition assembly, and the carbon source addition assembly can add a carbon source to the fourth waste water inflow pipe 22, and the output end of the fourth waste water inflow pipe 22 Extending into the mixing chamber 28 and setting the mixing assembly, the mixing assembly includes:

[0099] Mixing box 62, the left side wall of the mixing box 62 communicates with the fourth waste water inflow pipe 22, the bottom wall of the mixing box 62 is provided with a discharge port 63, and a discharge pipe 64 is provided at the discharge port 63, and the discharge pipe The output end of 64 is connected with the input end of the denitrification water inlet pipe 33;

[0100] The third rotating shaft 65, the third rotating shaft 65 is arranged in the mixing box 62, the upper end of the third rotating shaft 65 is rotatably connected with the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com