Preparation method of crisaborole intermediate

A technology of crisborole and intermediates, applied in the field of drug synthesis, can solve the problems of undisclosed preparation methods, increased reaction energy consumption, inconvenient operation, etc., to reduce the reaction temperature and the use of water separators, reduce content, Effect of improving product yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

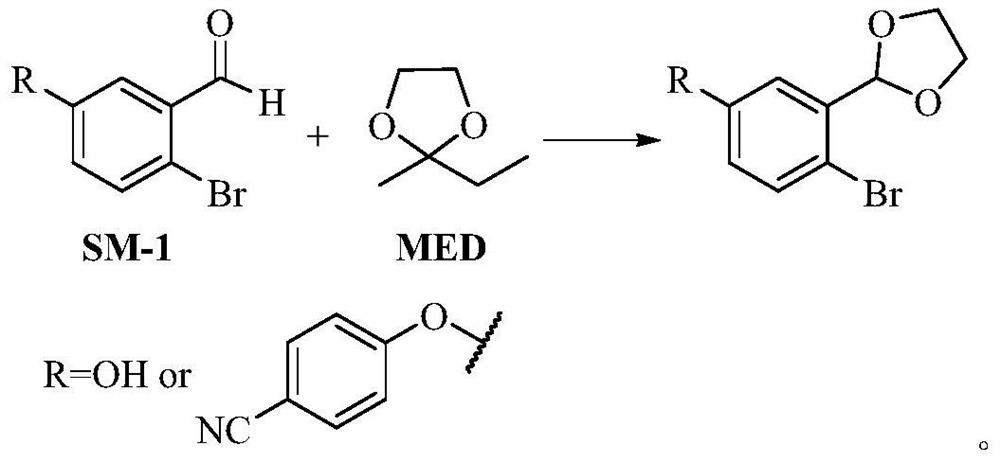

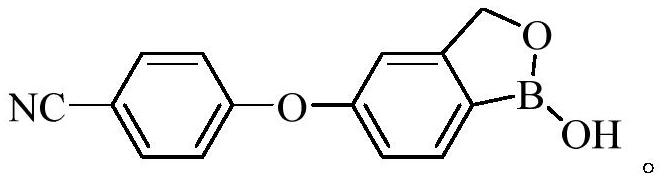

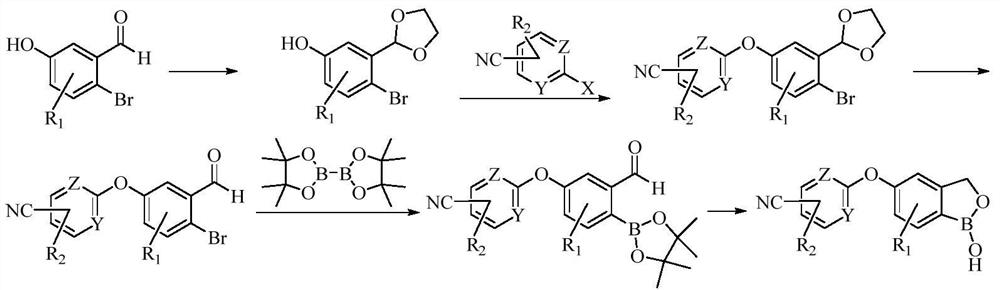

Method used

Image

Examples

Embodiment 1

[0039] At room temperature, 2-bromo-5-hydroxybenzaldehyde (SM-1, 20.10g, 0.10mol), butanone ethylene glycol ketal (MED, 15.10g, 0.13mol), p-toluenesulfonic acid (0.86g, 0.005 mol) was added to dry dichloromethane (300ml), and the temperature was controlled at 20-25°C until the reaction was completed. Then, saturated sodium bicarbonate solution (150ml) was added and stirred for 10-15min, and then the organic layer was separated and purified water (150ml×3 ), washed with saturated brine (150ml), dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated to dryness under reduced pressure to obtain 4-bromo-3-(1,3-dioxolane-2-yl)phenol. The yield is 97.5%, and the purity is 99.83%.

Embodiment 2

[0041] At room temperature, 2-bromo-5-hydroxybenzaldehyde (SM-1, 20.10g, 0.10mol), MED (12.78g, 0.11mol), 1R-(-)-10-camphorsulfonic acid (1.16g, 0.005mol ) was added into dry dichloromethane (300ml), and the temperature was controlled at 20-25°C until the reaction was completed. Then, saturated sodium bicarbonate solution (150ml) was added and stirred for 10-15min, then the organic layer was separated and purified water (150ml×3) Washing, washing with saturated brine (150ml), drying over anhydrous sodium sulfate, filtering, and concentrating the filtrate to dryness under reduced pressure is 4-bromo-3-(1,3-dioxolan-2-yl)phenol, yield 96.9%, 99.79% pure.

Embodiment 3

[0043] At room temperature, 2-bromo-5-hydroxybenzaldehyde (SM-1, 20.10g, 0.10mol), MED (11.62g, 0.10mol), 1S-(+)-10-camphorsulfonic acid (1.16g, 0.005mol ) was added into dry dichloromethane (300ml), and the temperature was controlled at 20-25°C until the reaction was completed. Then, saturated sodium bicarbonate solution (150ml) was added and stirred for 10-15min, then the organic layer was separated and purified water (150ml×3) Washing, washing with saturated brine (150ml), drying over anhydrous sodium sulfate, filtering, and concentrating the filtrate to dryness under reduced pressure is 4-bromo-3-(1,3-dioxolan-2-yl)phenol, yield 96.7%, 99.77% pure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com