Dispersing agent for permanent magnetic ferrite material as well as preparation method and application of dispersing agent

A permanent magnet ferrite and dispersant technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems affecting production efficiency and yield, affecting product performance, magnet cracking, etc., to achieve low cost and improve fluidity , remanence and coercive force enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

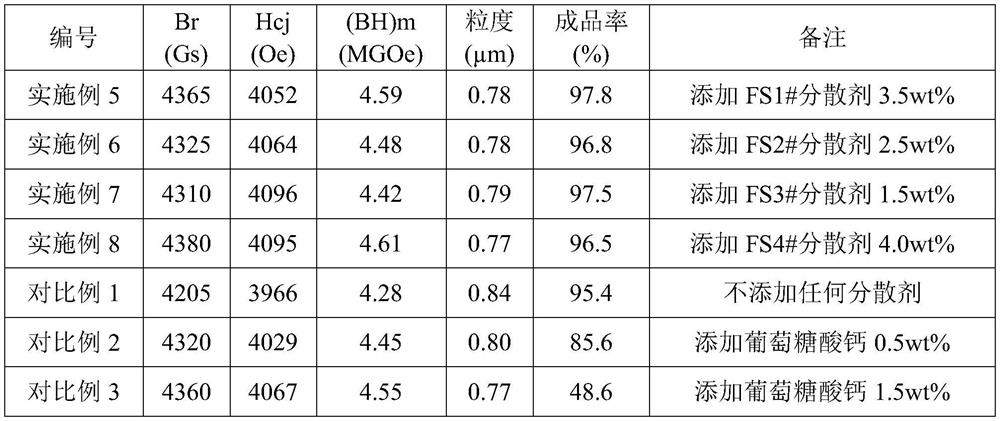

Examples

Embodiment 1

[0036] The synthesis of dispersant: get 10kg of commercially available citric acid solids and place them in a plastic bucket, add 10kg of tap water and fully stir and mix evenly until citric acid is completely dissolved; 6kg, stir evenly; (3) further in above-mentioned solution, add the sodium hydroxide solid of about 10kg and uniformly stir, the pH value of test solution is 6, obtains liquid dispersant of the present invention, numbering is FS1#.

Embodiment 2

[0038] The synthesis of dispersant: get commercially available citric acid solid 10kg and place it in a plastic bucket, add 10kg of tap water and fully stir and mix evenly until citric acid is completely dissolved; (2) add 10kg of ammonia water with a concentration of 25% , stir evenly; (3) further in above-mentioned solution, add the sodium hydroxide solid of about 5kg and evenly stir, the pH value of test solution is 5, obtains liquid dispersant of the present invention, numbering is FS2#.

Embodiment 3

[0040] The synthesis of dispersing agent: get commercially available citric acid solid 10kg and place in plastic bucket, add the tap water of 10kg and fully stir and mix evenly, until citric acid dissolves completely; , stir evenly; (3) further add the sodium hydroxide solid of about 8kg in above-mentioned solution and uniformly stir, and the pH value of test solution is 6, obtains liquid dispersant of the present invention, numbering is FS3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com