Treatment method for extracting heavy oil by using supercritical water and solvent

A technology of supercritical water and treatment method, which is applied in the treatment of hydrocarbon oil, solvent refining through deasphalting, petroleum industry, etc., can solve the problems of supercritical water treatment and separation capacity bottleneck, etc. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

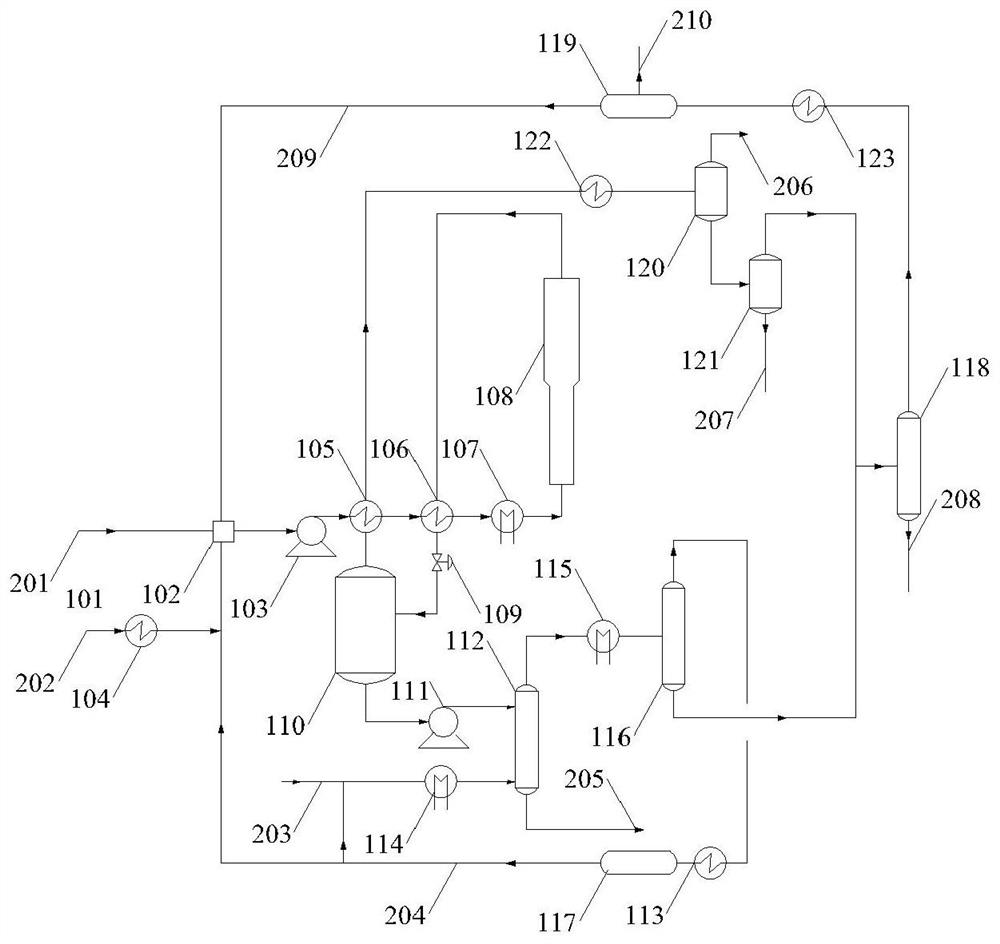

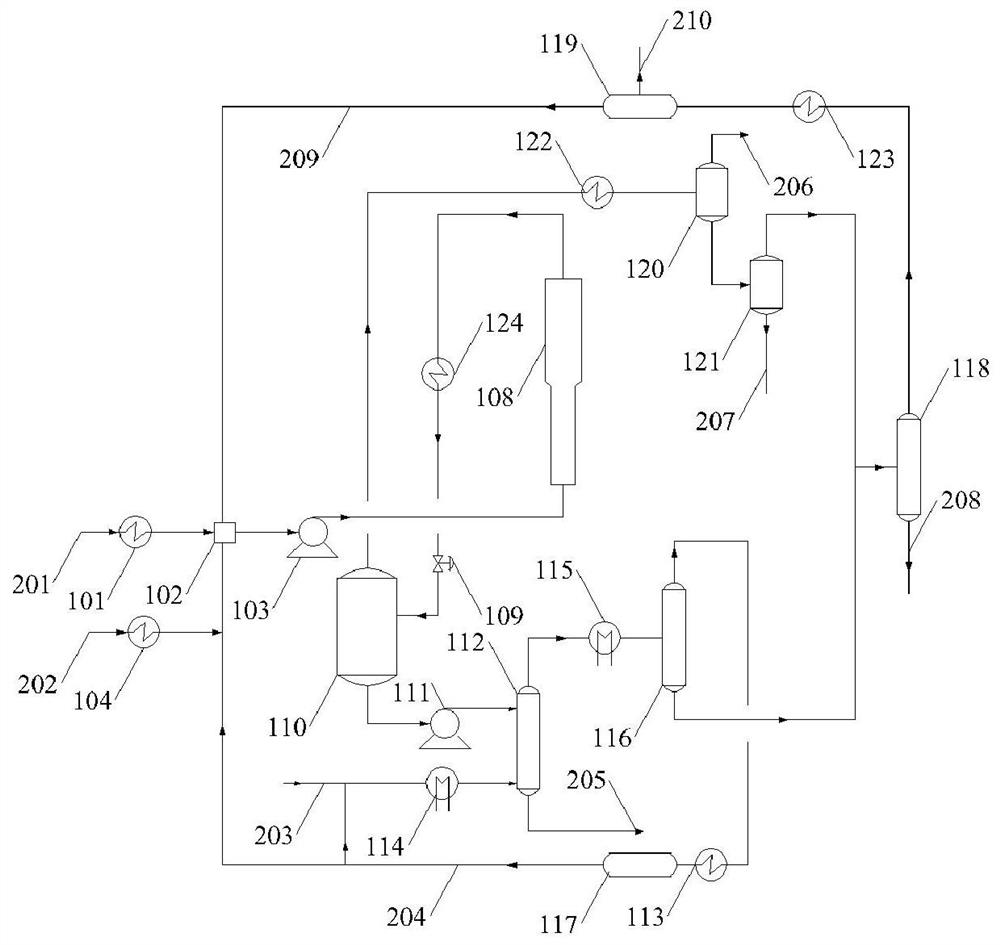

Method used

Image

Examples

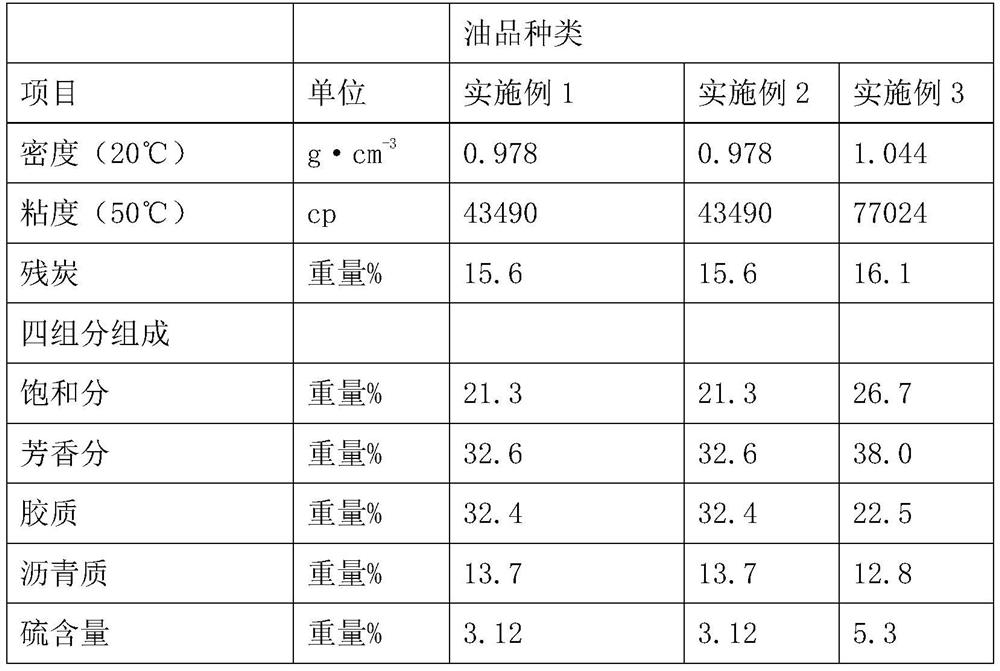

Embodiment 1

[0048] a) After the heavy oil raw material is heated to 90°C, the heavy oil raw material, water, solvent and light distillate oil are transported to the mixer for mixing to obtain the mixed raw material. The mass ratio of water to heavy oil raw material is 0.2:1, and the mass ratio of solvent to heavy oil raw material is 0.1 :1, the mass ratio of light distillate oil and heavy oil raw material is 0.01:1, and the properties of heavy oil are shown in Table 1.

[0049] b) The mixed raw material obtained in step a) is pressurized to 22.1MPa, heated to 374° C., then, the mixed raw material enters through the lower inlet of the supercritical water reactor, and the residence time of the mixed raw material in the supercritical water reactor is 40 minutes. pyrolysis reaction occurs;

[0050] c) The temperature of the reaction product described in step b) is lowered to 237° C., and the pressure is reduced to 3 MPa, and then transported to a hot high-pressure separator for separation to ...

Embodiment 2

[0058] a) After the heavy oil raw material is heated to 60°C, the heavy oil raw material, water, solvent and light distillate oil are transported to the mixer for mixing to obtain the mixed raw material. The mass ratio of water to heavy oil raw material is 5:1, and the mass ratio of solvent to heavy oil raw material is 5 :1, the mass ratio of light distillates and heavy oil feedstock is 0.25:1, and the properties of heavy oil are shown in Table 1.

[0059] b) The mixed raw material obtained in step a) is boosted to 35MPa, heated to 500° C., then, the mixed raw material enters through the lower inlet of the supercritical water reactor, and the residence time of the mixed raw material in the supercritical water reactor is 30 seconds. pyrolysis reaction occurs;

[0060] c) The temperature of the reaction product described in step b) is lowered to 266° C., and the pressure is lowered to 5 MPa, and then transported to a hot high-pressure separator for separation to obtain a gas pha...

Embodiment 3

[0068] a) The heavy oil raw material is oil sand asphalt heated to 90°C and water heated to 90°C, then the heavy oil raw material, water, solvent and light distillate oil are transported to the mixer for mixing to obtain the mixed raw material, and the mass ratio of water to heavy oil raw material is 1: 1. The mass ratio of solvent to heavy oil raw material is 0.4:1, and the mass ratio of light distillate oil to heavy oil raw material is 0.25:1. The properties of heavy oil are shown in Table 1.

[0069] b) The mixed raw material obtained in step a) is boosted to 25MPa, heated to 420° C., then, the mixed raw material enters through the lower inlet of the supercritical water reactor, and the residence time of the mixed raw material in the supercritical water reactor is 10 minutes. pyrolysis reaction occurs;

[0070]c) The temperature of the reaction product described in step b) is lowered to 260° C., and the pressure is lowered to 4 MPa. Then, it is sent to a hot high-pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com