Method for graded modification of thickened oil

A heavy oil and upgrading technology, which is applied in the treatment of hydrocarbon oil, hydrocarbon oil cracking, petroleum industry, etc., can solve the unsolved problems of pipeline or reactor blockage, shorten the residence time of each stage of reaction, and have no graded treatment, etc., to achieve Viscosity reduction, toxicity reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

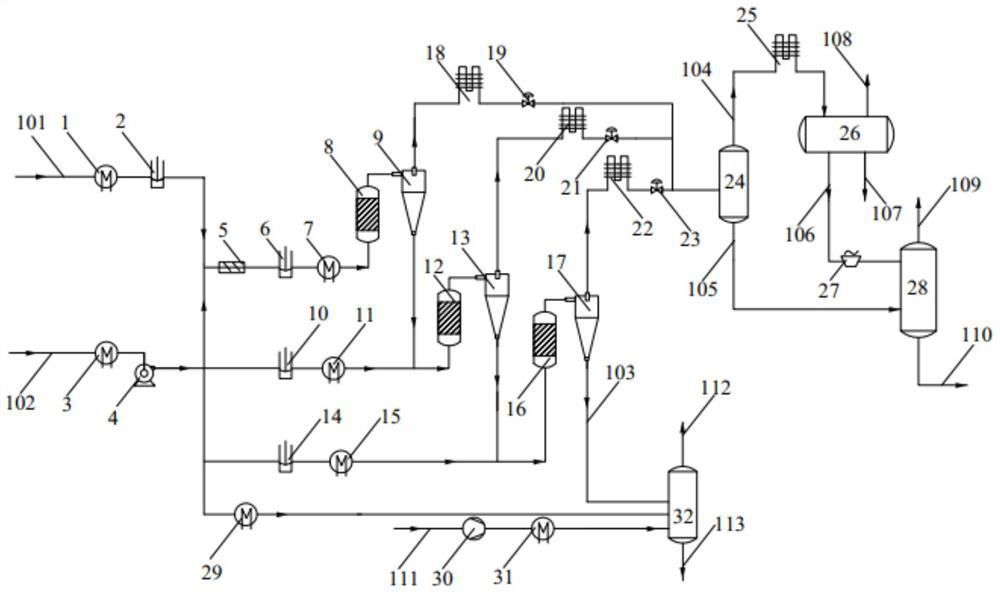

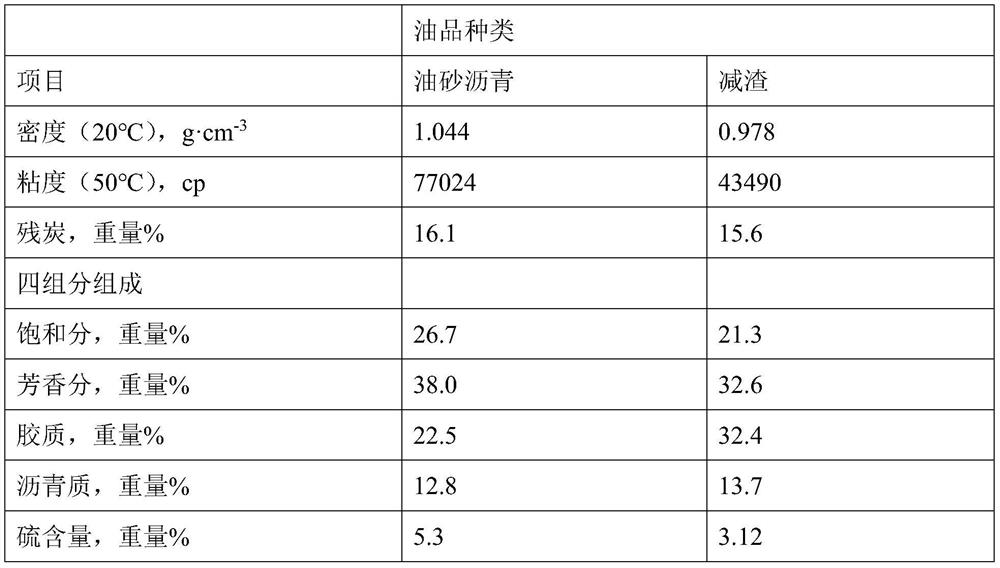

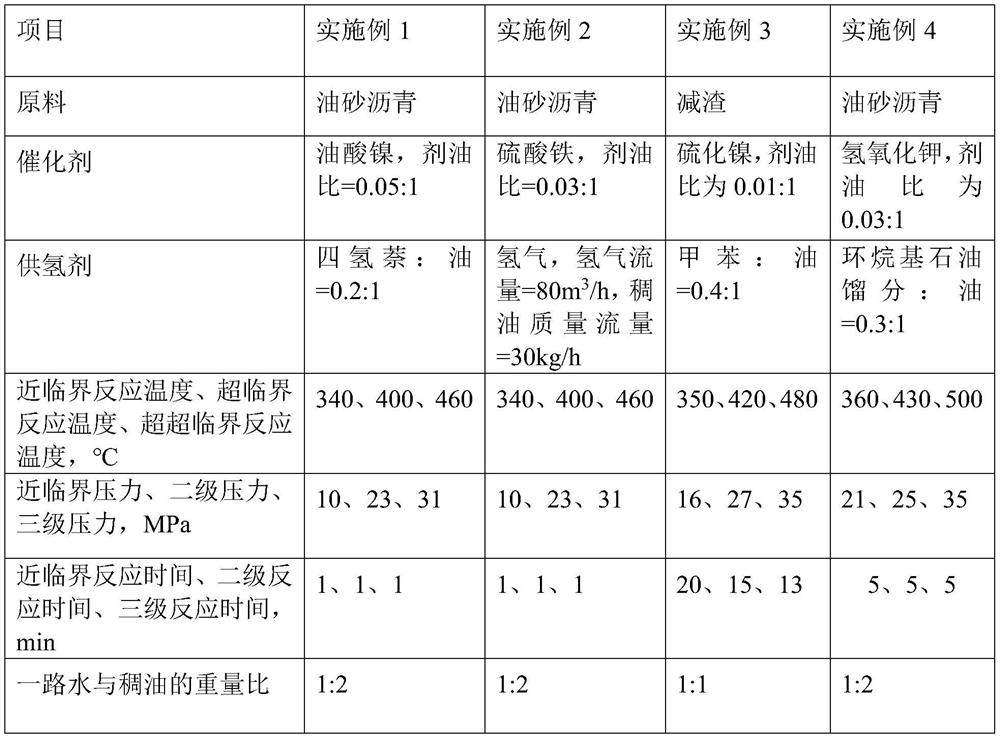

[0052] According to the method of the present invention, the heavy oil is upgraded by classification and pyrolysis. A set of vertical tube type three-stage pyrolysis reaction equipment is used, which consists of three pyrolysis reactors connected in series. The first-stage pyrolysis reactor is a near-critical water reactor, and the second-stage pyrolysis reactor is a supercritical water reaction. The third-stage pyrolysis reactor is an ultra-supercritical water reactor, and there is a cyclone separator behind each pyrolysis reactor. The main body of the pyrolysis reactor is a single standpipe, which is fed from the inlet at the lower end and discharged from the outlet at the upper end. The pressures in the three pyrolysis reactors were controlled by three back pressure valves, respectively.

[0053] The deionized water flow was connected, and the heating temperature of the deionized water was 60 °C. The temperature of the near-critical water reactor was controlled to be 340°...

Embodiment 2

[0055] According to the method of the present invention, the heavy oil is upgraded by classification and pyrolysis. A set of vertical tube type three-stage pyrolysis reaction equipment is used, which consists of three pyrolysis reactors connected in series. The first-stage pyrolysis reactor is a near-critical water reactor, and the second-stage pyrolysis reactor is a supercritical water reaction. The third-stage pyrolysis reactor is an ultra-supercritical water reactor, and there is a cyclone separator behind each pyrolysis reactor. The main body of the pyrolysis reactor is a single standpipe, which is fed from the inlet at the lower end and discharged from the outlet at the upper end. The pressures in the three pyrolysis reactors were controlled by three back pressure valves, respectively.

[0056] The difference from Example 1 is that the deionized water flow and the heavy oil raw material flow are simultaneously connected, the heating temperature of the heavy oil is 60°C, ...

Embodiment 3

[0058] According to the method of the present invention, the heavy oil is upgraded by classification and pyrolysis. A set of vertical tube type three-stage pyrolysis reaction equipment is used, which consists of three pyrolysis reactors connected in series. The first-stage pyrolysis reactor is a near-critical water reactor, and the second-stage pyrolysis reactor is a supercritical water reaction. The third-stage pyrolysis reactor is an ultra-supercritical water reactor, and there is a cyclone separator behind each pyrolysis reactor. The main body of the pyrolysis reactor is a single standpipe, which is fed from the inlet at the lower end and discharged from the outlet at the upper end. The pressures in the three pyrolysis reactors were controlled by three back pressure valves, respectively.

[0059] A stream of deionized water was introduced, and the heating temperature of the deionized water was 70 °C. The temperature of the near-critical water reactor was controlled to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com