Combination method for heavy oil modification

A technology of heavy oil upgrading and combined methods, which is applied in the direction of only multi-stage series refining process treatment, etc., can solve the problems of low value of deoiled bitumen, poor quality of pipeline oil products, and inability to realize high value-added utilization of oil sand bitumen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

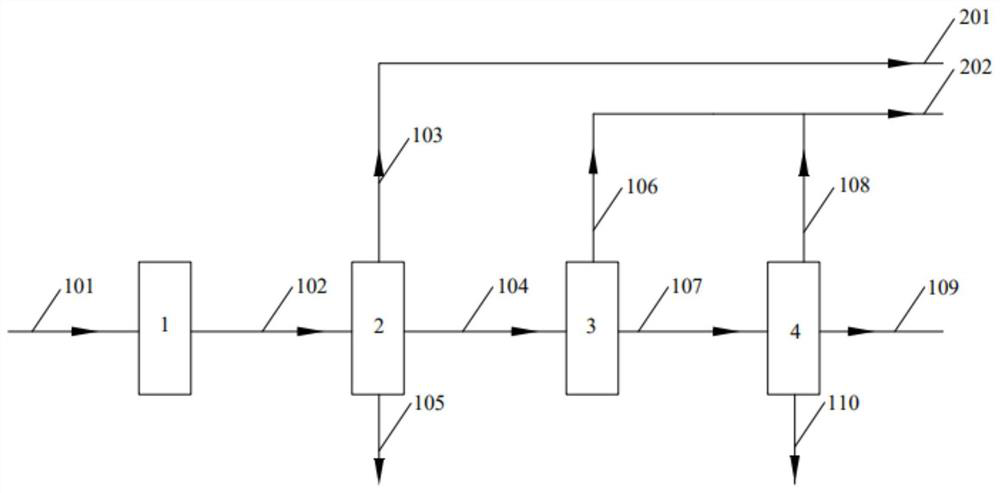

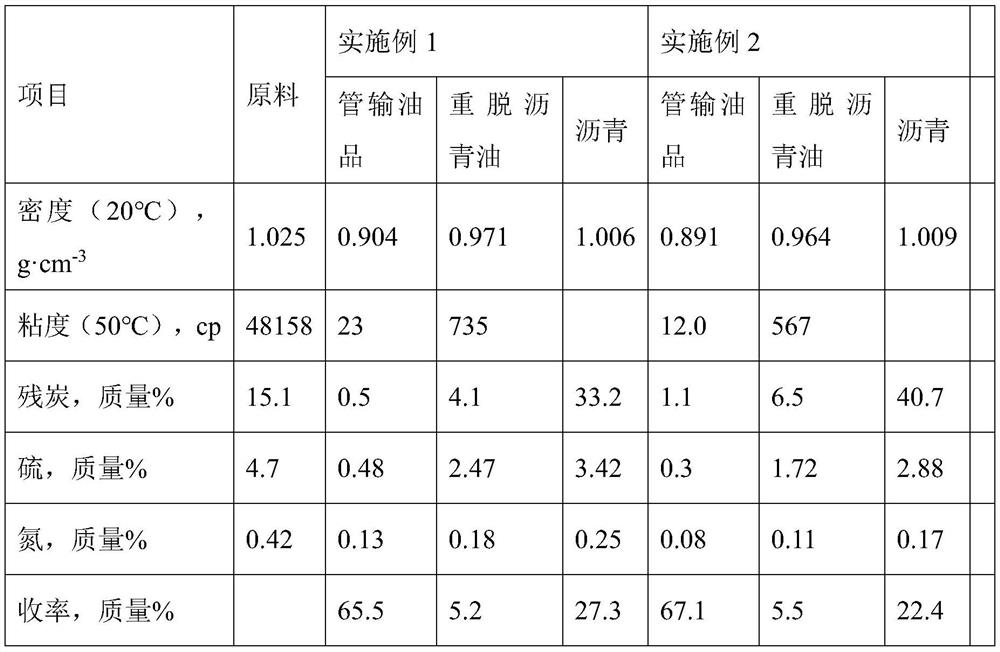

[0047] The heavy oil is treated according to the combined method of the four processes of raw material pretreatment, supercritical water modification, vacuum distillation and solvent deasphalting provided by the invention.

[0048] Using Canadian oil sand bitumen as raw material, remove solid impurities after heating, and mix heavy oil and water to form an oil-water mixture according to the water-oil mass ratio of 0.2:1. The oil-water mixture is heated to 374°C, pressurized to 22.1MPa, and then transported to the supercritical water reactor. Under the action of supercritical water, the heavy oil undergoes a pyrolysis reaction. The reaction time is controlled at 60min, and the reaction product is the modified oil. The modified oil is dehydrated and desalted to obtain hydrothermal modified oil. The hydrothermally upgraded oil is subjected to vacuum distillation to obtain light distillate oil and heavy distillate oil, and the split point of light distillate oil and heavy distilla...

Embodiment 2

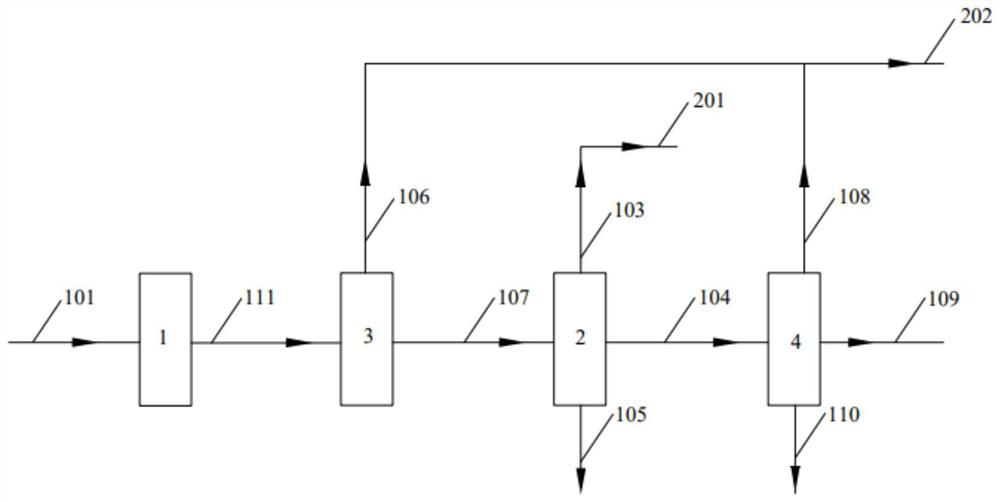

[0050] The heavy oil is treated according to the combined method of the four processes of raw material pretreatment, supercritical water modification, vacuum distillation and solvent deasphalting provided by the invention.

[0051] Using Canadian oil sand bitumen as the raw material, after heating, the solid impurities are removed, and the heavy oil and water are mixed according to the water-oil mass ratio of 4:1 to form an oil-water mixture. The oil-water mixture is heated to 600°C, pressurized to 50MPa, and then transported to the supercritical water reactor. Under the action of supercritical water, the heavy oil undergoes a pyrolysis reaction. The reaction time is controlled at 0.1min, and the reaction product is the modified oil. The modified oil is dehydrated and desalted to obtain hydrothermal modified oil. The hydrothermally upgraded oil is subjected to vacuum distillation to obtain light distillate oil and heavy distillate oil, and the split point of light distillate o...

Embodiment 3

[0053] The heavy oil is treated according to the combined method of the four processes of raw material pretreatment, supercritical water modification, vacuum distillation and solvent deasphalting provided by the invention.

[0054] Using Canadian oil sand bitumen as raw material, remove solid impurities after heating, and mix heavy oil and water to form an oil-water mixture according to the water-oil mass ratio of 1:1. The oil-water mixture is heated to 410°C, pressurized to 25MPa, and then transported to the supercritical water reactor. Under the action of supercritical water, the heavy oil undergoes a pyrolysis reaction. The reaction time is controlled within 10 minutes, and the reaction product is the modified oil. and cracked gas, the modified oil is dehydrated and desalted to obtain hydrothermal modified oil. The hydrothermally upgraded oil is subjected to vacuum distillation to obtain light distillate oil and heavy distillate oil, and the split point of light distillate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com