Method for jointly treating heavy oil by supercritical water and supersonic separator

A supersonic separator and supercritical water technology, which is applied in the field of heavy oil upgrading, can solve the problems of increasing the risk of clogged pipelines and reactors, increasing the amount of coke, etc., to achieve light weight conversion, separation, and operating costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

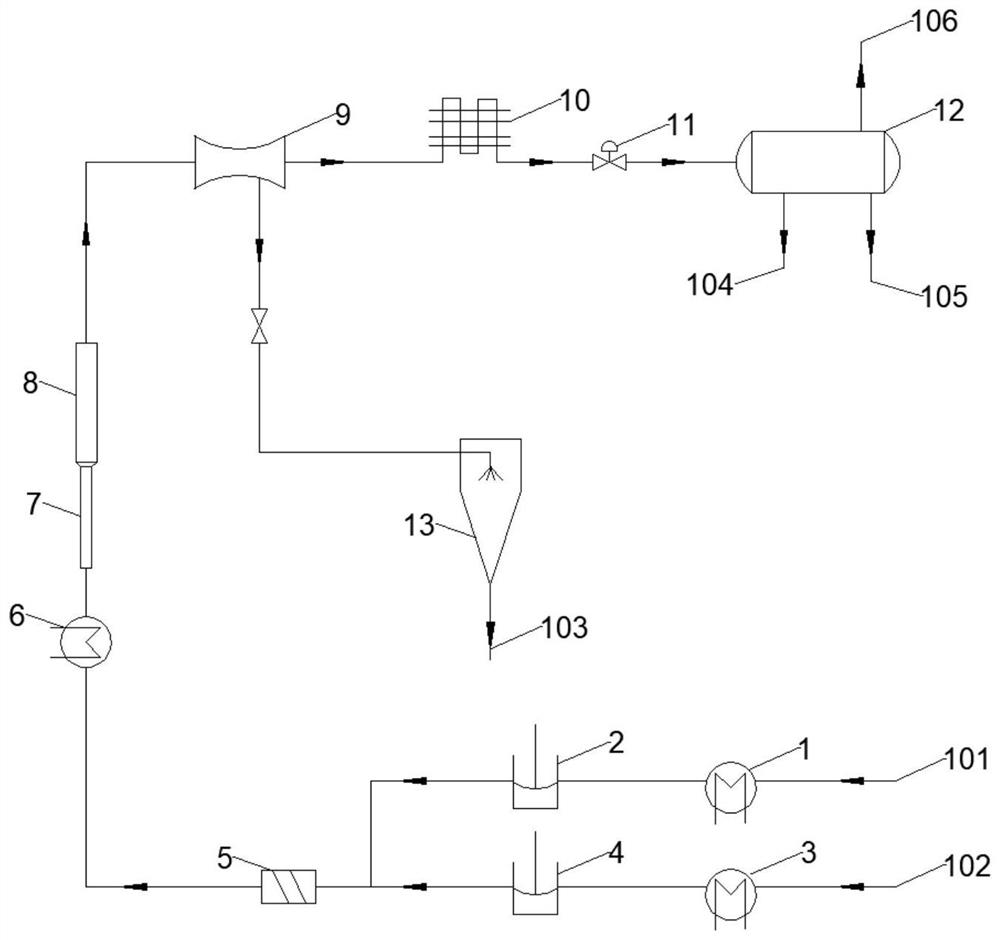

[0040] This example is used to illustrate the method of co-processing heavy oil with supercritical water and supersonic separator provided by the present invention.

[0041] On the supercritical water reforming heavy oil device equipped with two-stage upflow supercritical water reactors, the inner diameter of the first-stage standpipe supercritical water reactor is 12mm, the height is 4m, and the second-stage standpipe supercritical water reactor The inner diameter of the reactor is 20mm and the height is 4m.

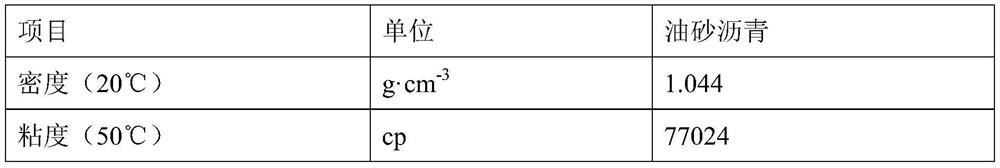

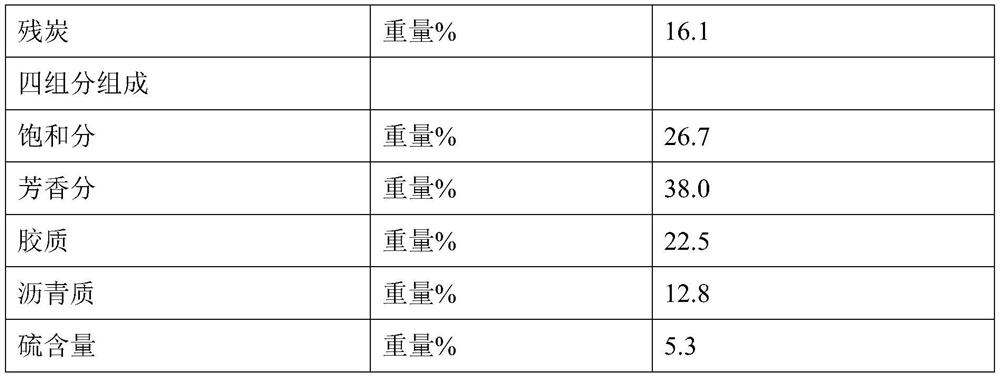

[0042] The mass flow rate of deionized water is 14kg / h. The deionized water is heated to 60°C and pressurized to 23MPa by a diaphragm pump. Oil sand bitumen is used as raw material. The properties of the heavy oil are shown in Table 1. The mass flow rate of the heavy oil is 7kg / h. The raw material of the heavy oil is heated to 60°C, pressurized to 23MPa by a diaphragm pump, and the oil-water mixture is heated to 400°C by a heater. , transported to the inlet of the firs...

Embodiment 2

[0044] This example is used to illustrate the method of co-processing heavy oil with supercritical water and supersonic separator provided by the present invention.

[0045] On the supercritical water reforming heavy oil device equipped with two-stage upflow supercritical water reactors, the inner diameter of the first-stage standpipe supercritical water reactor is 12mm, the height is 4m, and the second-stage standpipe supercritical water reactor The inner diameter of the reactor is 20mm and the height is 4m.

[0046] The mass flow rate of deionized water is 14kg / h. The deionized water is heated to 70°C and pressurized to 23MPa by a diaphragm pump. Using oil sand bitumen as raw material, the properties of the heavy oil are shown in Table 1. The mass flow rate of the heavy oil is 7kg / h. The heavy oil raw material is heated to 70°C, pressurized to 23MPa by a diaphragm pump, and the oil-water mixture is heated to 420°C by a heater. Transported to the inlet of the primary supercr...

Embodiment 3

[0048] This example is used to illustrate the method of co-processing heavy oil with supercritical water and supersonic separator provided by the present invention.

[0049] On the supercritical water reforming heavy oil device equipped with two-stage upflow supercritical water reactors, the inner diameter of the first-stage standpipe supercritical water reactor is 12mm, the height is 4m, and the second-stage standpipe supercritical water reactor The inner diameter of the reactor is 20mm and the height is 4m.

[0050] The mass flow rate of deionized water is 20kg / h. The deionized water is heated to 80°C and pressurized to 25MPa by a diaphragm pump. Using oil sand asphalt as raw material, the properties of the heavy oil are shown in Table 1. The mass flow rate of the heavy oil is 30kg / h. The raw material of the heavy oil is heated to 70°C, pressurized to 25MPa by a diaphragm pump, and the oil-water mixture is heated to 450°C by a heater. , transported to the inlet of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com