Low-erucic acid rapeseed oil and production process thereof

A technology of canola oil and production process, which is applied in the field of canola oil and its production process, can solve the problems of loss of nutrients, waste of energy and time, strong polarity of phenolic substances, etc., and achieve retention More, high oil yield, mild condition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

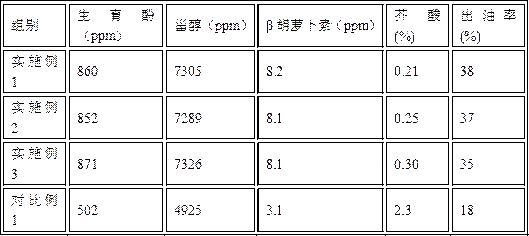

Examples

Embodiment 1

[0030] A production process of canola oil, comprising the following steps:

[0031] (1) Clean the rapeseed, remove debris, deflated seeds, and impurities;

[0032] (2) Moisture conditioning is carried out on the rapeseed from which impurities have been removed, so that the moisture content thereof is 0.8wt%;

[0033] (3) Crushing and sieving the rapeseed obtained in the previous step, the mesh number is 50 mesh, and the pressing pressure is 15MPa to obtain primary crude oil;

[0034] (4) Take 0.8% water of primary crude oil weight, 0.15% weight compound enzyme of primary crude oil weight, mix, stir evenly, add to primary crude oil, carry out enzymatic hydrolysis, enzymatic hydrolysis time 11h, temperature 36 ℃ ; Wherein the compound enzyme comprises 0.05% lipase of primary crude oil weight, 0.05% cellulase of primary crude oil weight, 0.05 papain of primary crude oil weight;

[0035] (5) After enzymatic hydrolysis, add petroleum ether for extraction, the amount of petroleum ...

Embodiment 2

[0038] A production process of canola oil, comprising the following steps:

[0039] (1) Clean the rapeseed, remove debris, deflated seeds, and impurities;

[0040] (2) Moisture conditioning is carried out on the rapeseed from which impurities have been removed, so that the moisture content thereof is 1wt%;

[0041] (3) Crushing and sieving the rapeseed obtained in the previous step, the mesh number is 60 mesh, and the pressing pressure is 20MPa to obtain primary crude oil;

[0042] (4) Take 0.1% water of primary crude oil weight and 00.3% weight compound enzyme of primary crude oil weight, mix, stir evenly, add to primary crude oil, carry out enzymatic hydrolysis, enzymatic hydrolysis time 12h, temperature 40℃ ; Wherein the compound enzyme comprises 0.1% lipase of primary crude oil weight, 0.1% cellulase of primary crude oil weight, 0.1% papain of primary crude oil weight;

[0043](5) After enzymatic hydrolysis, add petroleum ether for extraction, the amount of petroleum eth...

Embodiment 3

[0046] A production process of canola oil, comprising the following steps:

[0047] (1) Clean the rapeseed, remove debris, deflated seeds, and impurities;

[0048] (2) Moisture conditioning is carried out on the rapeseed from which impurities have been removed, so that the moisture content thereof is 0.5wt%;

[0049] (3) Crushing and sieving the rapeseed obtained in the previous step, the mesh number is 40 mesh, and the pressing pressure is 10MPa to obtain primary crude oil;

[0050] (4) Take 0.05% water of the primary crude oil weight and 0.09% weight compound enzyme of the primary crude oil weight, mix, stir evenly, add to the primary crude oil, and carry out enzymatic hydrolysis, the enzymatic hydrolysis time is 10h, and the temperature is 35°C ; Wherein composite enzyme comprises 0.03% lipase of primary crude oil weight, 0.03% cellulase of primary crude oil weight, 0.03% papain of primary crude oil weight;

[0051] (5) After enzymatic hydrolysis, add petroleum ether for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com