Method for detecting gel particles in PAN spinning solution

A spinning dope and detection method technology, applied in the field of PAN wet spinning, can solve the problems of error in measurement results, time-consuming, inability to quantitatively express the size and number of gel particles, etc., and achieves short operation time and operation. Simple, improved spinning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

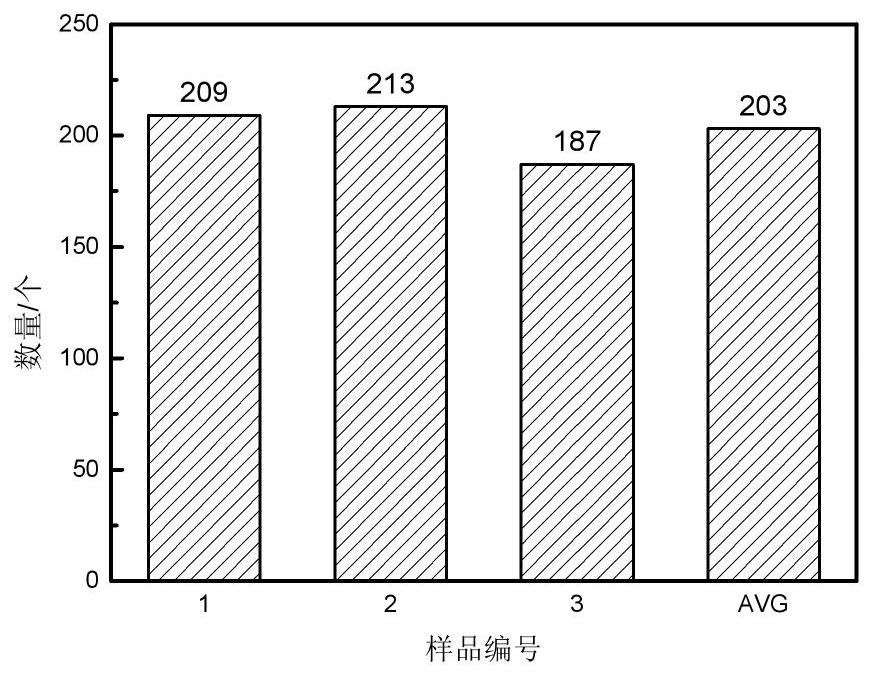

Embodiment 1

[0034] A kind of detection method of gel particle in PAN spinning dope, concrete steps are as follows:

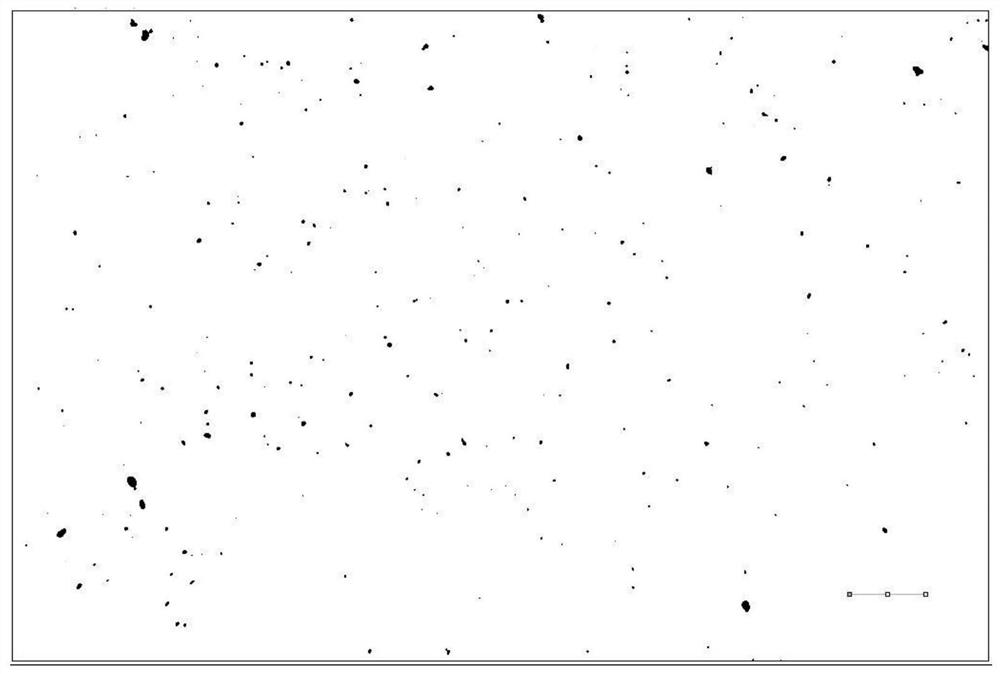

[0035] (1) PAN spinning stock solution I whose solvent is NaSCN solution, filter out the impurities in the stock solution through a filter cloth with a pore size of 100 μm, then stand at 25°C for 8 hours, and then defoam in a vacuum oven at a temperature of 35°C After 6 hours, the spinning stock solution II was obtained; using the method of heterogeneous film formation, the spinning stock solution II was poured on a glass plate with a flat and smooth surface and a bacterial cellulose film, and the AFA-II automatic film applicator was used to spread it evenly into 100 μm thickness, then put the prepared film into a tray filled with distilled water for 30 minutes, and finally rinse repeatedly to remove the solvent in the film, and air dry naturally to obtain a PAN film;

[0036] The solid content of PAN in the above-mentioned spinning dope II is 5%, the weight average molecul...

Embodiment 2

[0047] A kind of detection method of gel particle in PAN spinning dope, concrete steps are as follows:

[0048] (1) The PAN spinning stock solution I whose solvent is NaSCN solution, filter the impurities in the stock solution through a filter cloth with a pore size of 100 μm, then stand at 26°C for defoaming for 10 hours, and then defoam in a vacuum oven at a temperature of 37°C After 5 hours, the spinning stock solution II was obtained; using the method of heterogeneous film formation, the spinning stock solution II was poured on a glass plate with a smooth surface and a bacterial cellulose film, and the AFA-II automatic film applicator was used to spread it evenly into 100 μm thickness, then put the prepared film into a tray filled with distilled water for 30 minutes, and finally rinse repeatedly to remove the solvent in the film, and dry naturally to obtain a PAN film containing gel particles;

[0049] The solid content of PAN in the above-mentioned spinning dope II is 10%...

Embodiment 3

[0060] A method for detecting particles in a PAN spinning stock solution gel, the specific steps are as follows:

[0061] (1) The PAN spinning stock solution I whose solvent is NaSCN solution, filter the impurities in the stock solution through a filter cloth with a pore size of 100 μm, then stand at 27°C for 9 hours, and then defoam in a vacuum oven at a temperature of 39°C After 4 hours, the spinning stock solution II was obtained; using the method of heterogeneous film formation, the spinning stock solution II was poured on a glass plate with a flat and smooth surface and a bacterial cellulose film, and the AFA-II automatic film applicator was used to spread it evenly into 50 μm thickness, then put the prepared film into a tray filled with distilled water for 30 minutes, and finally rinse repeatedly to remove the solvent in the film, and dry naturally to obtain a PAN film containing gel particles;

[0062] The solid content of PAN in the above-mentioned spinning dope II is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com