Preparation method of carbon dioxide premixed cement-based composite material

A technology of carbon dioxide and composite materials, applied in the field of building materials, can solve the problems of complex process flow, inability to achieve carbonization, etc., and achieve the effect of broad application market, reduction of cement consumption, and excellent pore distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

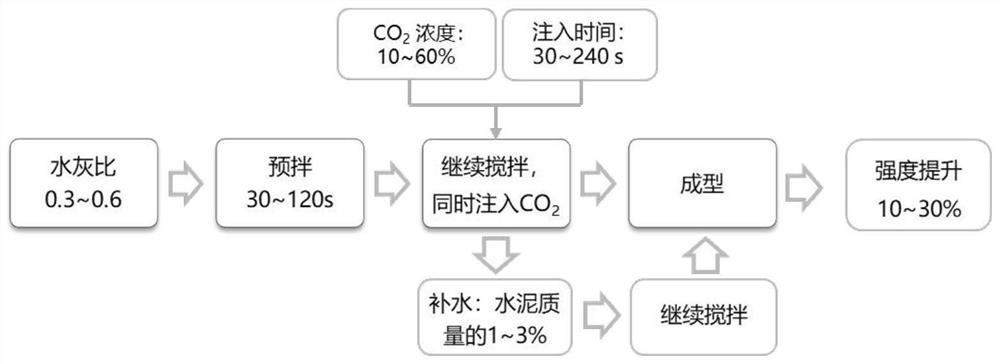

[0028] Example 1. A preparation method of carbon dioxide ready-mixed cement-based composite material, the operation method is as follows figure 1 As shown, the specific implementation steps are as follows: Accurately weigh the material according to the water-cement ratio of 0.5, pre-mix the water and cement evenly, and then continuously feed the mixed gas with a carbon dioxide concentration of 20% into the closed mixer, and the injection time The time is 2min, the gas flow rate is 100L / min, and the stirring speed is 60-80r / min. After the aeration is completed, add 1% water by mass of cement to the mixing pot to make up for the lost fluidity. Put the stirred slurry in a 20×20×20mm steel mold, vibrate for 30s, seal it with a black plastic film, and release it after natural curing for 24 hours; put the test block into a room with a temperature of 20°C and a relative humidity of 95%. Cultivate in a standard curing box until 28 days old.

[0029] The cement is ordinary Portland ...

Embodiment 2

[0035] Example 2. A preparation method of carbon dioxide ready-mixed cement-based composite material, the operation method is as follows figure 1 As shown, the specific implementation steps are as follows: Accurately weigh the material according to the water-cement ratio of 0.4, pre-mix the water and cement evenly, and then continuously feed the mixed gas with a carbon dioxide concentration of 20% into the closed mixer, and the injection time The time is 2min, the gas flow rate is 100L / min, and the stirring speed is 60-80r / min. After the aeration is completed, add 1% water by mass of cement to the mixing pot to make up for the lost fluidity. Put the stirred slurry in a 20×20×20mm steel film, vibrate for 30s, seal it with a black plastic film, and release it after natural curing for 24 hours; put the test block into a room with a temperature of 20°C and a relative humidity of 95%. Cultivate in a standard curing box until 28 days old.

[0036] The cement is ordinary Portland ...

Embodiment 3

[0042] Example 3. A preparation method of carbon dioxide ready-mixed cement-based composite material, the operation method is as follows figure 1shown, including the following steps:

[0043] Step 1: Inject carbon dioxide-containing gas into the cement slurry being stirred in a closed state for 30s to 240s;

[0044] Step 2: When the fluidity of the cement paste is significantly reduced, add water of 1% to 3% of the cement mass to restore its original fluidity; the carbonation reaction of ready-mixed concrete will consume a certain amount of water, resulting in cement and concrete Reduced flow of material. This reduction can be compensated by secondary hydration in the later stage of stirring, and a certain amount of strength gain can be achieved. Through subsequent natural maintenance, the cement paste and concrete materials will continue to be hydrated until they can be put into use;

[0045] Step 3: After completing Step 2, add sand, stones and admixtures to the cement p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com