Preparation method of high-energy insensitive aluminum-containing explosive

An insensitive and high-energy technology, applied in explosives processing equipment, explosives, explosives composite components, etc., can solve the problems of high friction, impact and shock wave sensitivity, low volumetric combustion enthalpy and energy density, and limited applications, achieving less solvent, The effect of light droplet drift and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

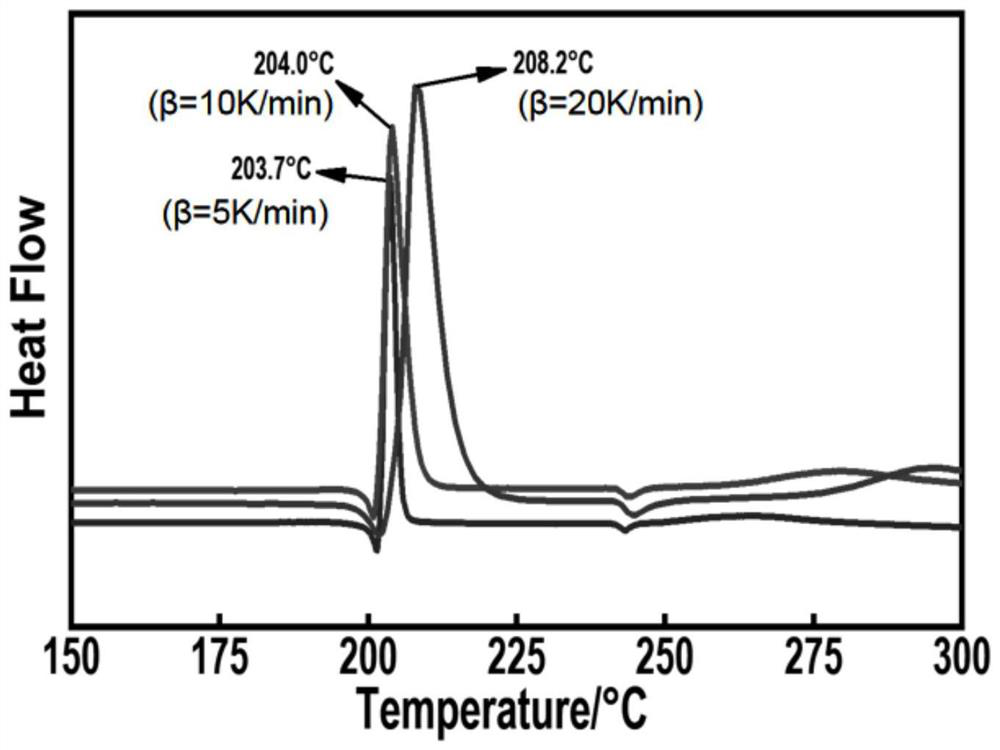

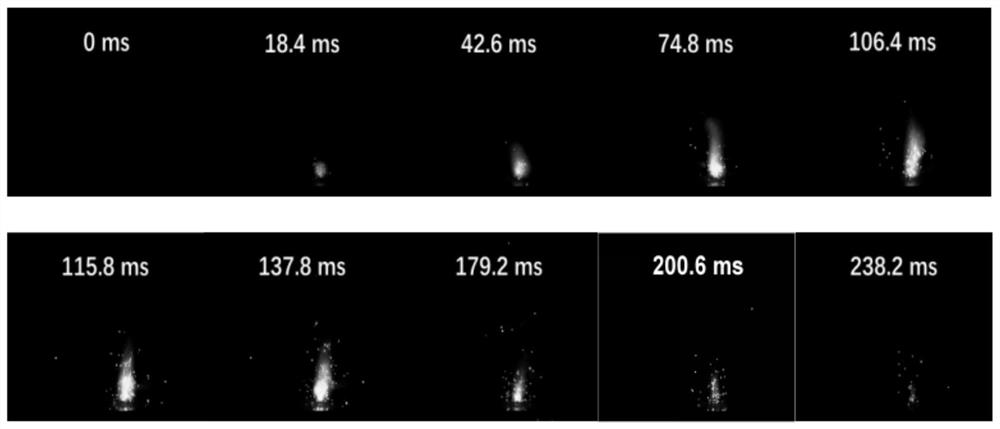

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of high-energy insensitivity aluminum-containing explosives, comprising the following steps:

[0027] Step 1, get 0.04g nitrocellulose (NC), 1g RDX and 0.58g ammonium perchlorate (AP) and dissolve in the mixed solvent (4mL) of acetone and DMF (volume ratio 1:1), form mixed solution;

[0028] Step 2: Take 0.42g of nano-Al powder and add it to the mixed solution, and disperse it ultrasonically for 40 minutes to form a stable suspension;

[0029] Step 3. Inhale the suspension with a 5mL syringe with a needle, fix it on the electrostatic sprayer, receive it with an aluminum foil baffle, connect the positive pole to the needle of the syringe, and connect the negative pole to the aluminum foil baffle. 0.05ml / min, the negative pressure is controlled at -12kV, and the positive pressure is controlled at 12kV, so that the suspension forms a stable spray with a cone angle of 30° at the needle nozzle, and RDX / AP / NC / Al aluminum-containing explosives are obtained...

Embodiment 2

[0032] A preparation method of high-energy insensitivity aluminum-containing explosives, comprising the following steps:

[0033] Step 1, get 0.04g nitrocellulose (NC), 1g RDX and 0.58g ammonium perchlorate (AP) and dissolve in the mixed solvent (4mL) of acetone and DMF (volume ratio 1:1), form mixed solution;

[0034] Step 2: Add 5g of nano-aluminum powder and 100g of dopamine solution into a supercritical carbon dioxide reactor, fill with carbon dioxide, stir for 45min at a temperature of 40°C and a pressure of 15MPa, release the pressure, and separate to obtain pretreated nano-aluminum powder ; Add 0.42g of pretreated nano-Al powder into the mixed solution, ultrasonically disperse for 40min, and form a stable suspension; the dopamine solution is prepared with distilled water, which contains 1mg / mL dopamine and 10mM tris buffer solution, pH=8.5; Pretreatment of nano-aluminum powder can improve the dispersibility of nano-aluminum powder, reduce its agglomeration, make it more...

Embodiment 3

[0040] A preparation method of high-energy insensitivity aluminum-containing explosives, comprising the following steps:

[0041] Step 1. Dissolve 0.02g of nitrocellulose (NC), 1g of HMX and 0.458g of ammonium perchlorate (AP) in a mixed solvent (4mL) of acetone and dimethyl sulfoxide (volume ratio 1:1) to form a mixed solution;

[0042] Step 2: Take 0.35g of nano-Al powder and add it to the mixed solution, and disperse with magnetic stirring for 30 minutes to form a stable suspension;

[0043]Step 3. Inhale the suspension with a 5mL syringe with a needle, fix it on the electrostatic sprayer, receive it with an aluminum foil baffle, connect the positive pole to the needle of the syringe, and connect the negative pole to the aluminum foil baffle. 0.01ml / min, the negative pressure is controlled at -10kV, and the positive pressure is controlled at 10.95kV, so that the suspension forms a stable spray with a cone angle of 30° at the needle nozzle, and the HMX / AP / NC / Al aluminum-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Impact sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com