Breathable and moisture-permeable polyurethane resin for labor protection gloves and preparation method of breathable and moisture-permeable polyurethane resin

A polyurethane resin and labor protection glove technology, applied in the field of polyurethane resin, can solve the problems of sweat not being discharged in time, hand injury, poor air permeability and moisture permeability, etc., and achieve the effect of excellent moisture permeability and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

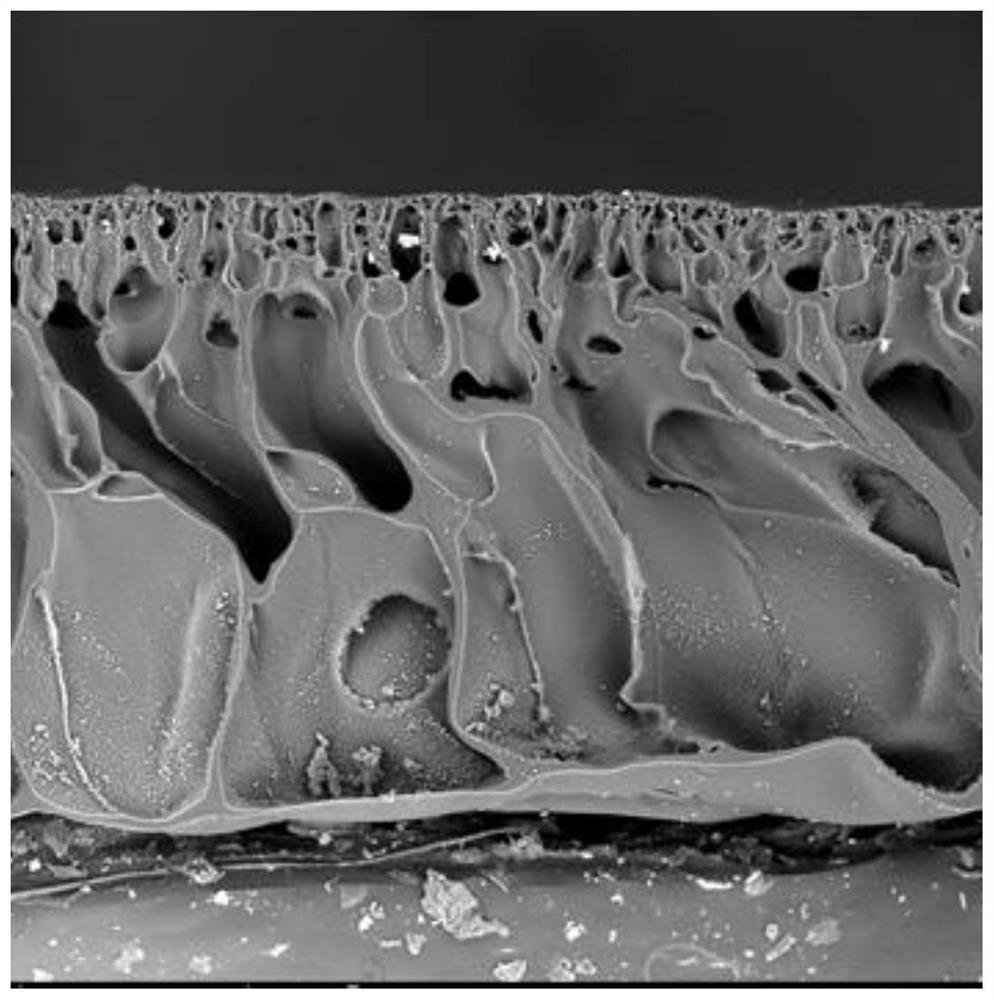

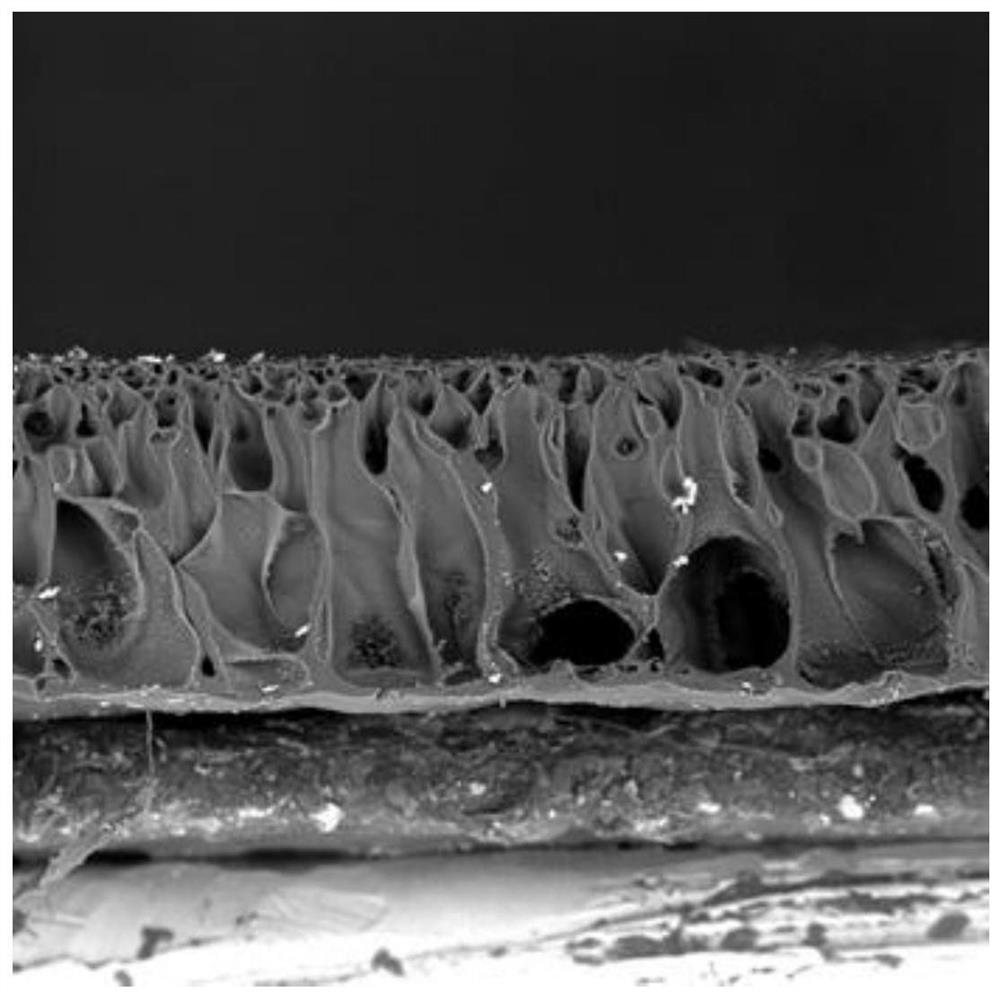

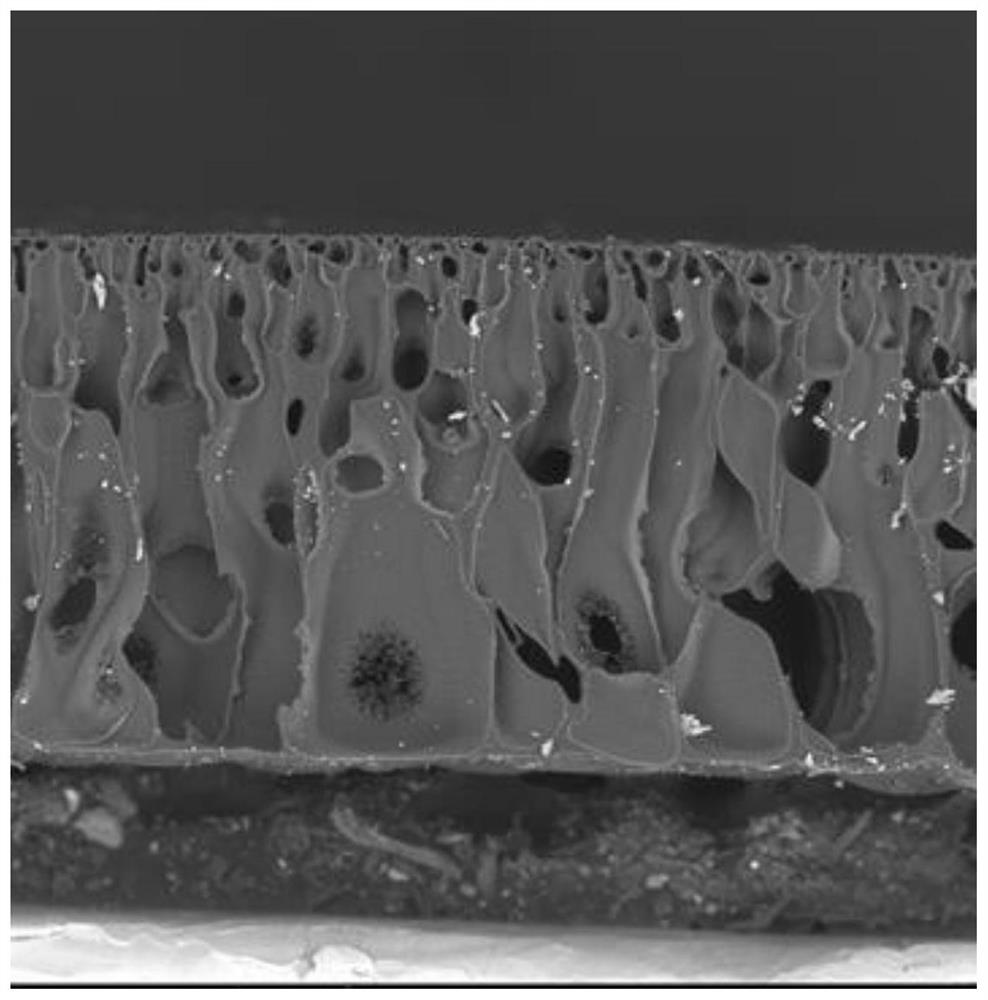

Image

Examples

Embodiment 1

[0032]

[0033] Put AA-EG-DEG with a number average molecular weight of 2000G / MOL, PEG-2000, antioxidants, phosphoric acid and an appropriate amount of DMF into a three-necked flask, stir evenly with a mechanical stirrer at high speed, raise the temperature to 50°C, and then add MDI to control the reaction The temperature is 70-75℃ for prepolymerization for 1 hour; after the prepolymerization is completed, add MDI to increase viscosity, and when the viscosity reaches 40-80Pa.s / 70℃, add part of DMF and EG; after fully stirring, add the remaining MDI, and control the temperature at React at 70-80°C to increase the viscosity, and depending on the reaction speed, add CATA (catalyst) as appropriate, add MDI moderately during the thickening process and gradually add DMF to dilute the viscosity until the viscosity reaches 300-350Pas / 25°C, add end capping DMF and methanol are used for capping, and then malic acid and additives are put in. After being completely stirred evenly, it is...

Embodiment 2

[0035]

[0036]

[0037]Put AA-BG with a number average molecular weight of 2000G / MOL, PEG-2000, antioxidants, phosphoric acid and an appropriate amount of DMF into a three-necked flask, stir evenly with a mechanical stirrer at high speed, raise the temperature to 50°C, then add MDI, and control the reaction temperature to Pre-polymerize at 70-75°C for 1 hour; add MDI to increase viscosity after pre-polymerization, and add part of DMF and EG when the viscosity reaches 40-80Pa.s / 70°C; add the remaining MDI after fully stirring, and control the temperature at 70- React at 80°C to increase the viscosity, and depending on the reaction speed, add CATA (catalyst) as appropriate, add MDI moderately during the thickening process and gradually add DMF to dilute the viscosity until the viscosity reaches 300-350Pas / 25°C, add end-capped DMF and Carry out capping with methanol, then put in malic acid and additives, after being completely stirred evenly, cool down and pour into a speci...

Embodiment 3

[0039]

[0040]

[0041] Put AA-EG-BG, PEG-2000, antioxidant, phosphoric acid and appropriate amount of DMF with a number average molecular weight of 2500G / MOL into a three-necked flask, stir evenly at high speed with a mechanical stirrer, raise the temperature to 50°C, and then add MDI to control the reaction temperature Pre-polymerize at 70-75°C for 1 hour; add MDI to increase viscosity after pre-polymerization, and add part of DMF and EG when the viscosity reaches 40-80Pa.s / 70°C; add the remaining MDI after fully stirring, and control the temperature at 70 Reaction at -80°C to increase viscosity, and depending on the reaction speed, add CATA (catalyst) as appropriate, add MDI moderately during the thickening process and gradually add DMF to dilute the viscosity until the viscosity reaches 300-350Pas / 25°C, add end-capped DMF Capped with methanol, then put in malic acid and additives, after being completely stirred evenly, cooled and poured into a special plastic bottle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com