Online variable-frequency annealing device for rigid fireproof cable

A fire-resistant cable and annealing device technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of difficult cable annealing and low temperature, and achieve the effect of improving annealing performance and uniform heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] For further understanding of the present invention, set forth in detail below in conjunction with accompanying drawing and embodiment:

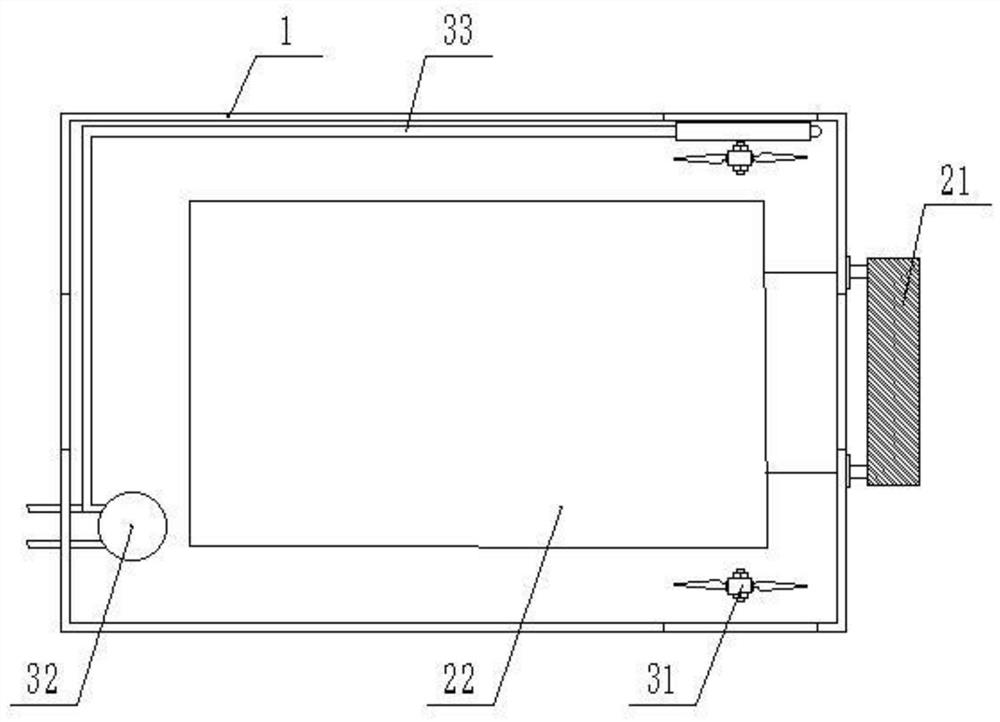

[0021] Such as figure 1 and figure 2 As shown: the online frequency conversion annealing device for rigid fireproof cables of the present invention includes: a housing 1, an induction heating module and a cooling module; the housing 1 is provided with an induction heating module and a cooling module, and the cable is heated by a heating coil;

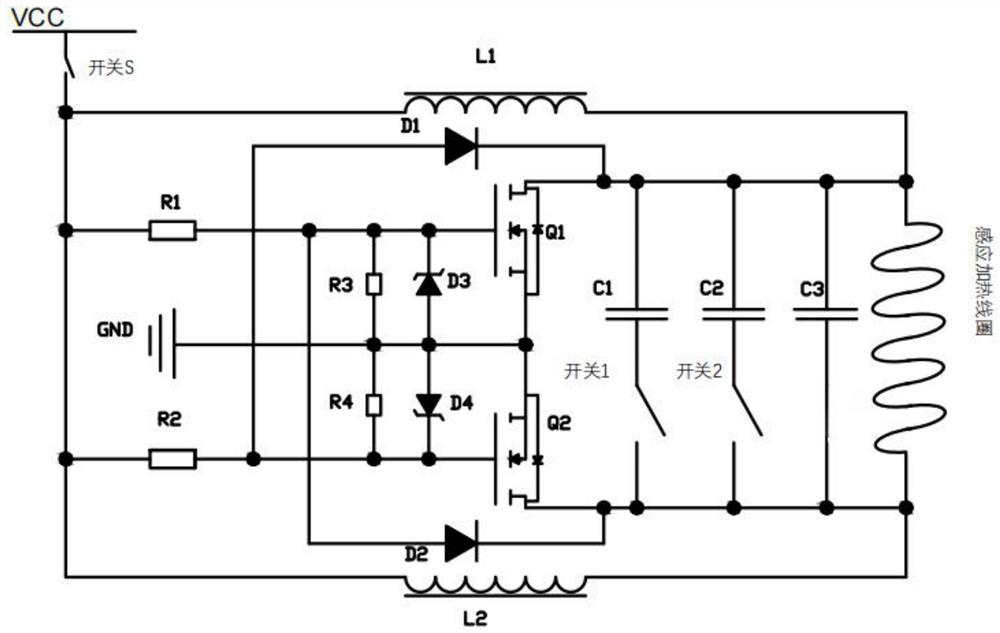

[0022] The induction heating module includes: heating coil 21 and frequency conversion control circuit 22; connect;

[0023] The frequency conversion control circuit 22 is: the positive pole of the power supply D is connected in parallel with one end of the inductance L1 and one end of the inductance L2, and the other end of the inductance L1 is connected in parallel with one end of the heating coil 21, one end of the heating capacitor group and the D pole of the field effect transistor Q1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com