On-chip light source modulation system

A technology of light source modulation and micro-ring modulator, which is applied in the field of microwave photonics, can solve the problem of narrow spectral width of optical frequency comb, and achieve the effect of high speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

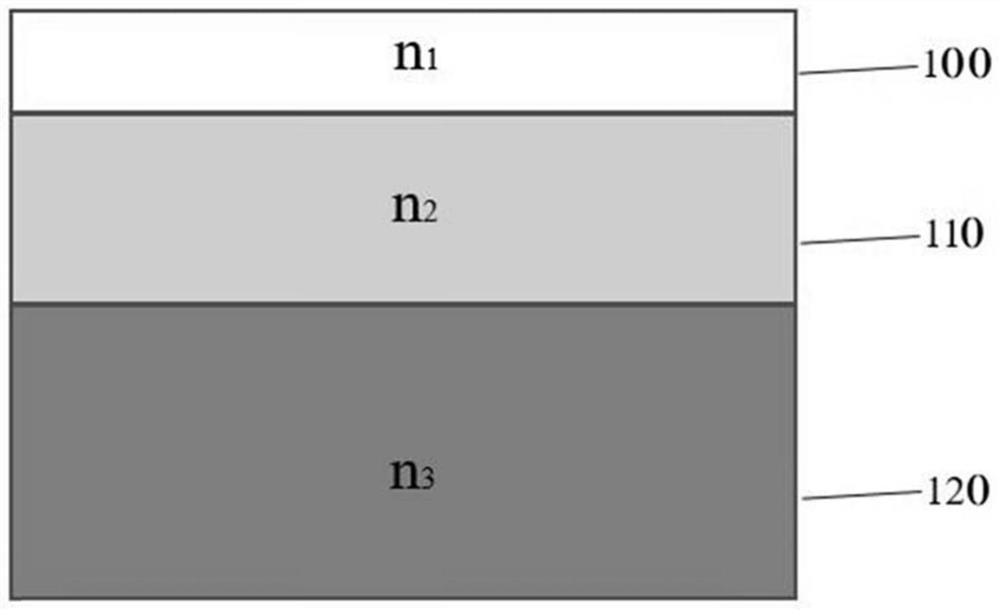

[0028] like figure 1 The on-chip light source modulation system shown is mainly divided into three layers, which are n from bottom to top 3 layer, n 2 layer, n 1 layer, where n 3 layer is a silicon substrate 120, n 2 The layer is a silicon dioxide buried oxide layer 110, n 1 The layer is a silicon nitride layer 100 , the height of the silicon substrate 120 is greater than the height of the silicon dioxide buried oxide layer 110 , and the height of the silicon dioxide buried oxide layer 110 is greater than the height of the silicon nitride layer 100 .

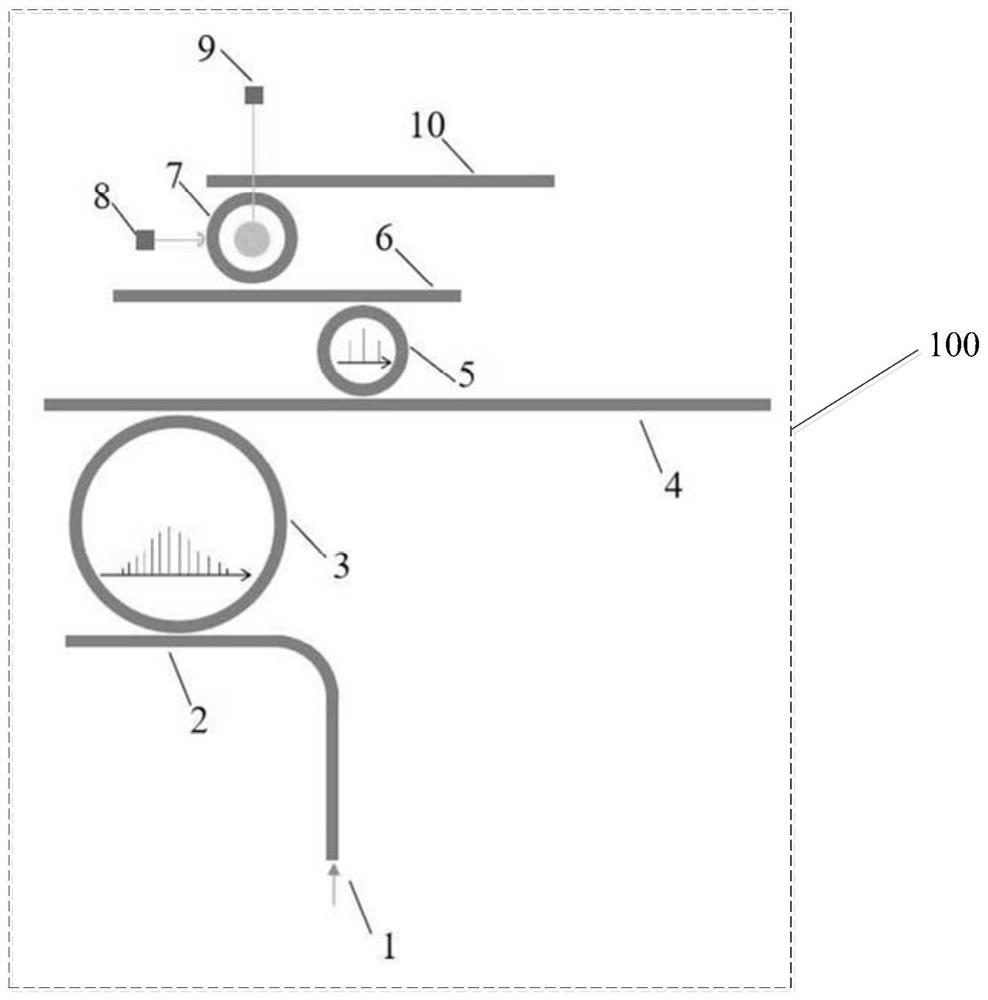

[0029] The structure of the silicon nitride layer 100 is as figure 2 As shown, it mainly includes a microring resonator 3, a microring filter 5, a microring modulator 7 and several waveguides. The radii of the microring modulator 7 and the microring filter 5 are equal, and the radius of the microring resonator 3 is larger than The radius of the microring filter 5. The specific positional relationship between the componen...

Embodiment 2

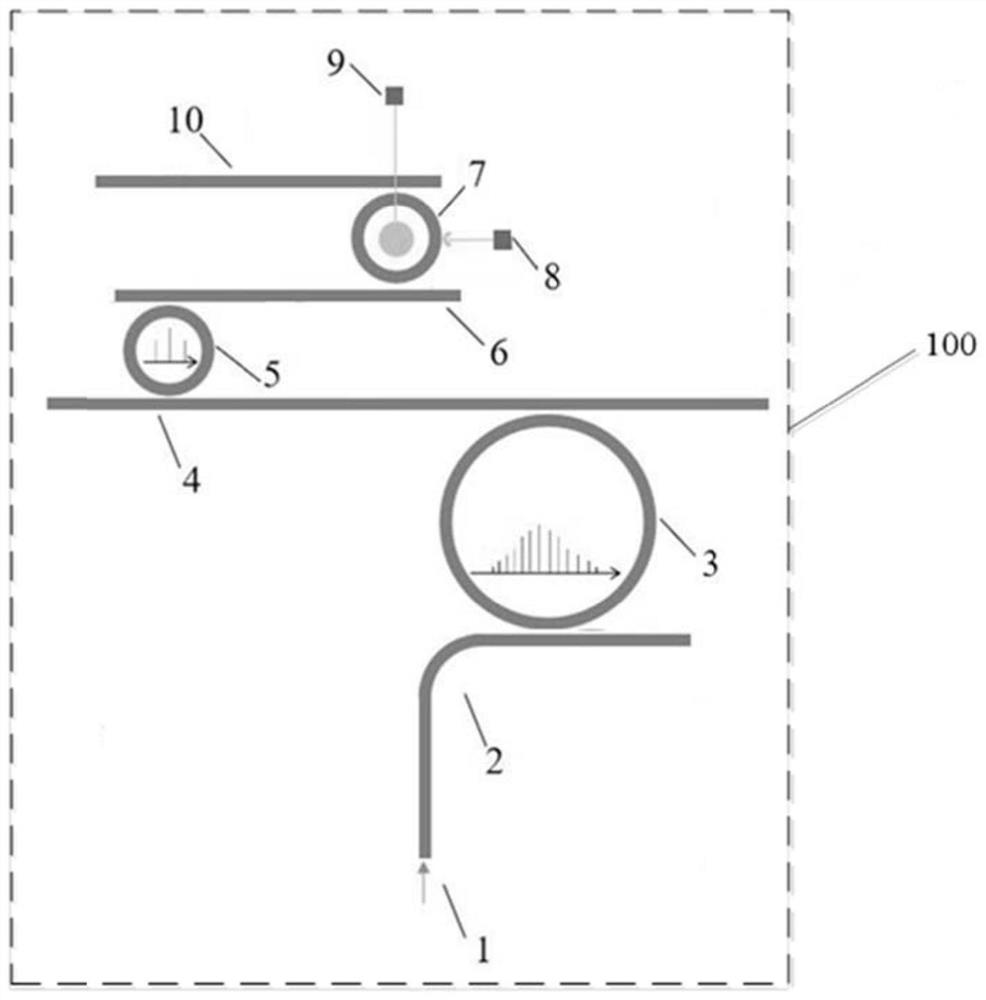

[0051] This embodiment proposes an on-chip light source modulation system, such as image 3 As shown, the system is the same as in Example 1 figure 2 The light source modulation system shown differs in that, figure 2 The micro-ring resonant cavity 3 is located on the left side of the second silicon nitride waveguide 4, the resonant filter 5 is located on the right side of the second silicon nitride waveguide 4 and the third silicon nitride waveguide 6, and the resonant modulator 7 is located on the silicon nitride The left side of the silicon third waveguide 6 and the silicon nitride fourth waveguide 10 .

[0052] In this embodiment, the microring resonant cavity 3 is located on the right side of the second silicon nitride waveguide 4, the resonant filter 5 is located on the left side of the second silicon nitride waveguide 4 and the third silicon nitride waveguide 6, and the resonant modulator 7 is located on the right side of the third silicon nitride waveguide 6 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com