Sweet almond oil microcapsule powdered oil and preparation method thereof

A technology of sweet almond oil and powdered oil, which is applied in microcapsule preparation, microsphere preparation, edible oil/fat and other directions, can solve the problems of rancidity and deterioration, difficult storage, and easy oxidation of sweet almond oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

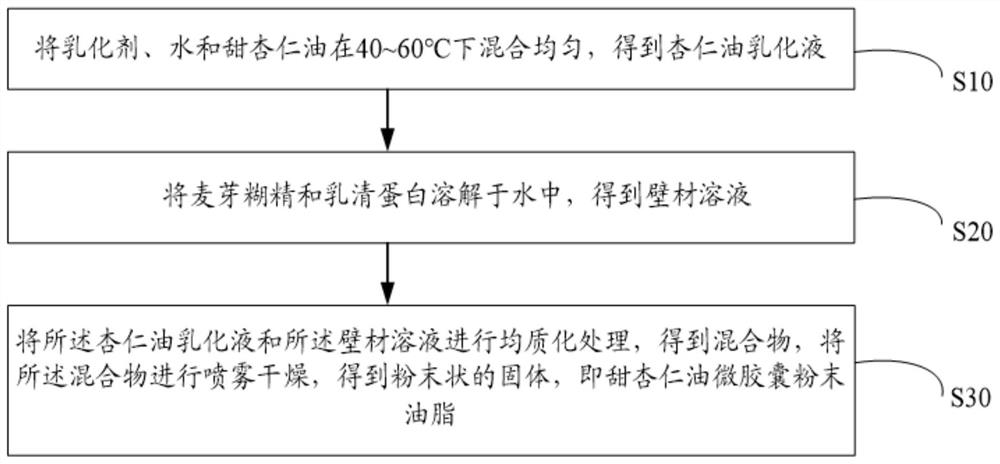

[0033] Further, the present invention also proposes a method for preparing sweet almond oil microcapsule powder oil as described above, figure 1 It is a schematic flow diagram of an embodiment of the preparation method of sweet almond oil microcapsule powder oil proposed by the present invention. see figure 1 , in one embodiment, the preparation method of described sweet almond oil microcapsule powder oil comprises the following steps:

[0034] Step S10, mixing the emulsifier, water and sweet almond oil uniformly at 40-60° C. to obtain an almond oil emulsion.

[0035] In one embodiment, the emulsifier includes at least one of tween, span and monoglyceride. The present invention does not limit the specific types of Tween and Span. Tween can be Tween-20, Tween 60 or Tween 80, and Span can be Span 20 or Span 80. Preferably, Span and Tween are respectively used as a hydrophilic emulsifier and a lipophilic emulsifier, and their compounding has a better effect on the stability of...

Embodiment 1

[0053] (1) Dehulling the sweet almonds, ventilating and drying until the water content of the sweet almonds is 4%, crushing, and passing through a 140-mesh sieve to obtain peeled sweet almonds, and pressing the peeled sweet almonds at 40°C to obtain crude almond oil , filter the almond crude oil to obtain cold-pressed sweet almond oil.

[0054] (2) The mixed solution of Tween and Span (the mass ratio of Span and Tween is 2:6), water and sweet almond oil (wherein, the addition of mixed solution is 2%, the addition of sweet almond oil is 15%) were uniformly mixed at 50° C. to obtain almond oil emulsion.

[0055] (3) Maltodextrin and whey protein (wherein the mass ratio of maltodextrin to whey protein is 1:3) are dissolved in water to obtain a wall material solution.

[0056] (4) Mix the almond oil emulsion and the wall material solution (wherein the mass ratio of the wall material in the wall material solution to the sweet almond oil is 4:1), and homogenize to obtain the mixtur...

Embodiment 2

[0058] (1) Peel the sweet almonds, dry them until the water content of the sweet almonds is 3%, pulverize them, and pass through a 100-mesh sieve to obtain peeled sweet almonds, then press the peeled sweet almonds at 40°C to obtain almond hair Oil, the crude almond oil is filtered to obtain cold-pressed sweet almond oil.

[0059] (2) Monoglyceride, water and sweet almond oil (wherein the addition amount of monoglyceride is 3%, and the addition amount of sweet almond oil is 10%) are uniformly mixed at 55° C. to obtain an almond oil emulsion.

[0060] (3) Maltodextrin and whey protein (wherein, the mass ratio of maltodextrin and whey protein is 1:4) are dissolved in water to obtain a wall material solution.

[0061] (4) Mix the almond oil emulsion and the wall material solution (wherein the mass ratio of the wall material in the wall material solution to the sweet almond oil is 3:1), and carry out homogenization treatment to obtain the mixture, and mix the mixture The content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com