Device and method for synthesizing spherical quartz powder

A technology of spherical quartz powder and quartz, which is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of spheroidization and low amorphization rate of particles, difficulty in large-scale production, complicated process, etc. The effect of easy size control, easy large-scale production, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

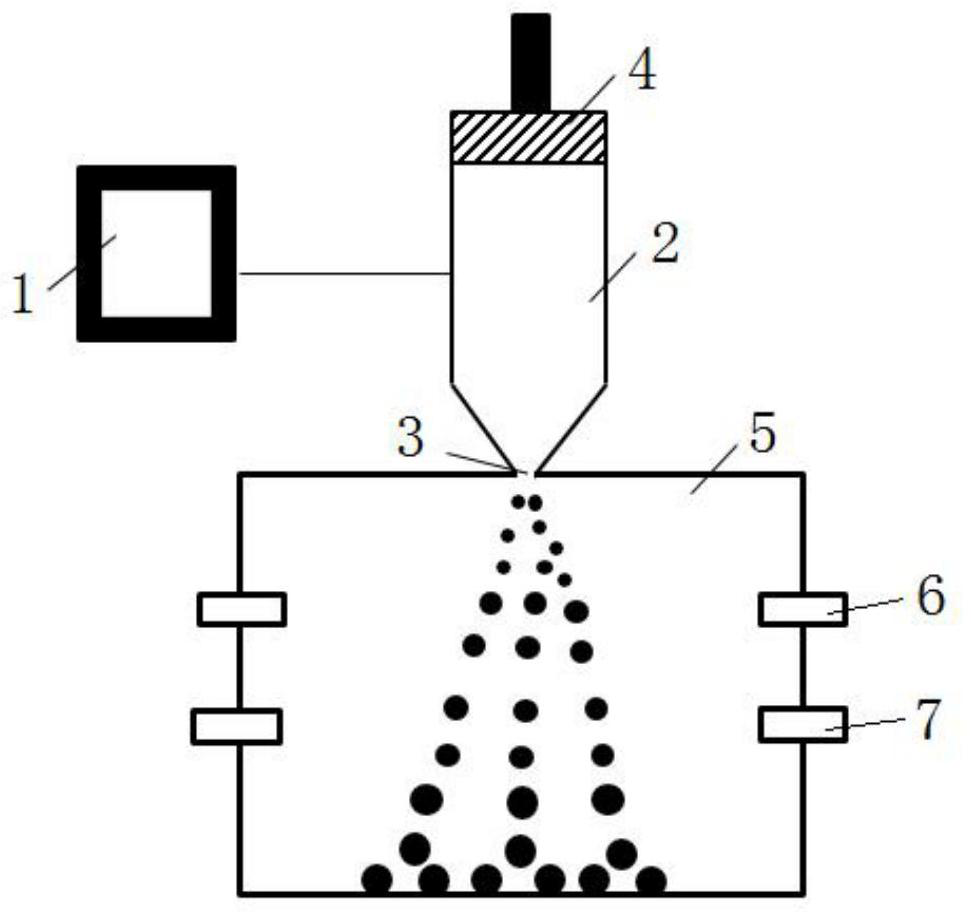

Image

Examples

Embodiment 1

[0029] Using quartz sand as the raw material, grind the quartz sand into powder and send it into the furnace for heating. The heating temperature is set at 2200°C. The completely melted quartz liquid is transferred to the spray chamber, and three atmospheres of pressure are applied to the liquid. Injected from a spray hole of 1.0mm, it is broken into small droplets in the atomization chamber. The temperature of the primary air is set at 50°C, and the speed is 0.1m / s. The temperature of the secondary air is set at 25°C, and the speed is 0.2m / s. .

Embodiment 2

[0031] Using quartz sand as raw material, grind the quartz sand into powder and send it into the furnace for heating. The heating temperature is set at 2000°C. The completely melted quartz liquid is transferred to the spray chamber, and five atmospheres of pressure are applied to the liquid. Injected from a spray hole of 1.0mm, it is broken into small droplets in the atomization chamber. The temperature of the primary air is set at 50°C, and the speed is 0.1m / s. The temperature of the secondary air is set at 25°C, and the speed is 0.2m / s. .

Embodiment 3

[0033] Using quartz sand as raw material, grind the quartz sand into powder and send it into the furnace for heating. The heating temperature is set at 2100°C. The completely melted quartz liquid is transferred to the spray chamber, and five atmospheres of pressure are applied to the liquid. It is injected from a spray hole of 0.5mm and broken into small droplets in the atomization chamber. The temperature of the primary air is set at 50°C, and the speed is 0.08m / s. The temperature of the secondary air is set at 25°C, and the speed is 0.15m / s. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com