Nano flame-resistant concrete protective coating and preparation method thereof

A technology for protecting coatings and concrete, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., to achieve the effect of improving adhesion, durability, and ultra-long weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

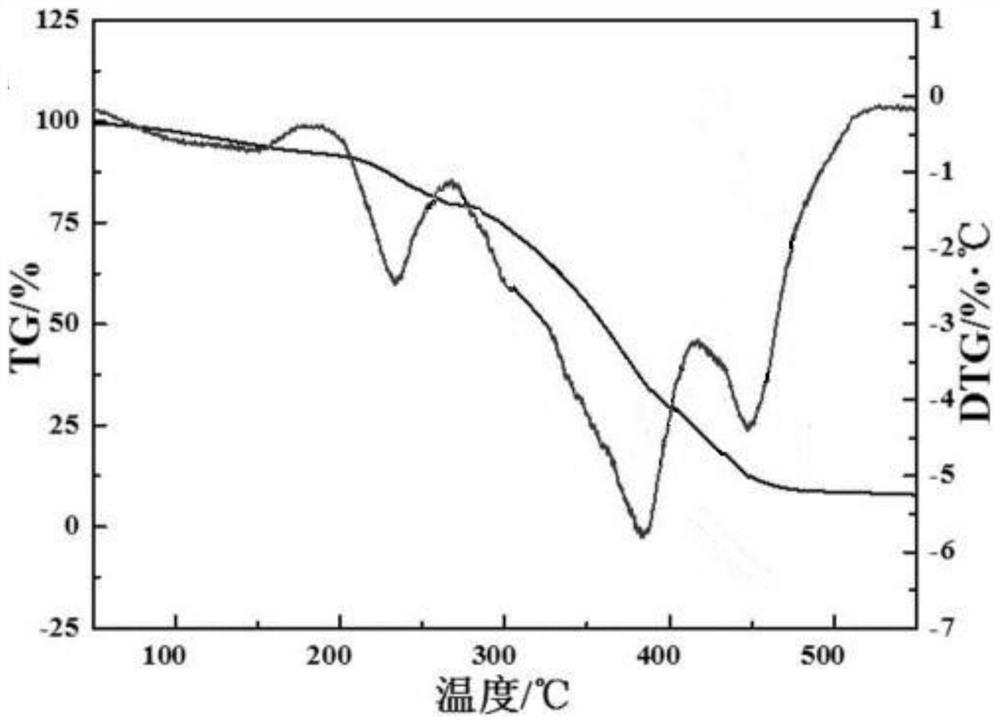

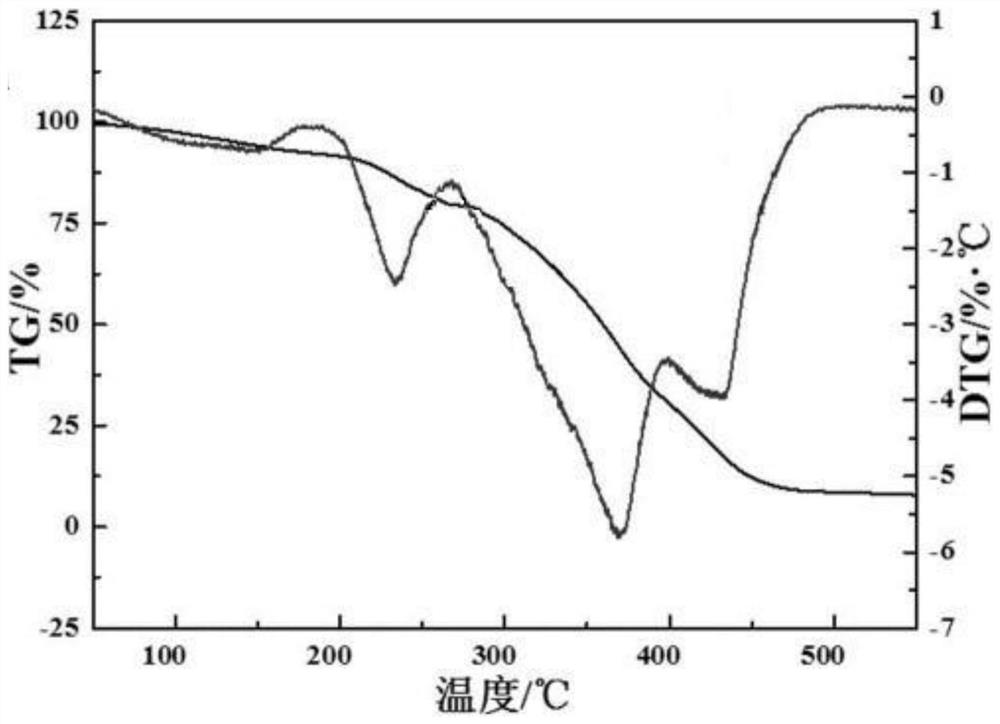

Image

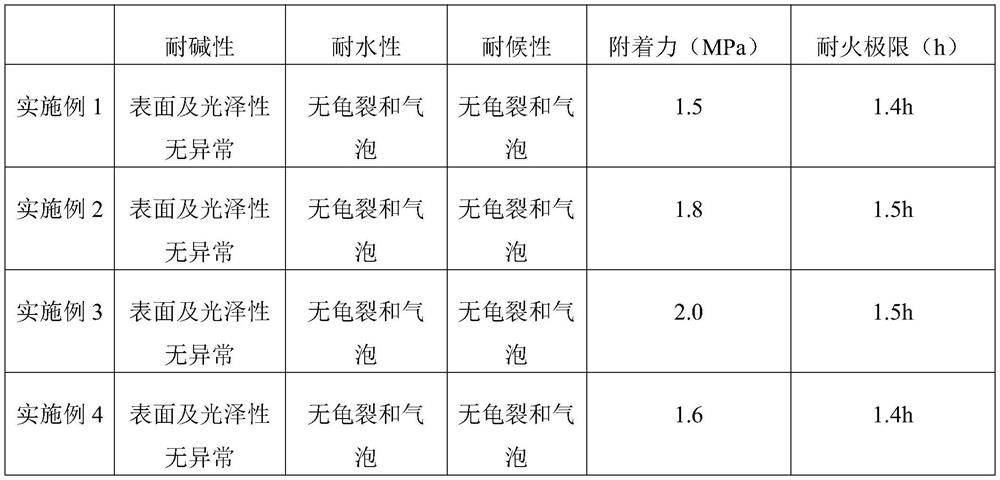

Examples

Embodiment 1

[0031] Providing a nano-flame-resistant concrete protective coating comprising 55 parts by weight of a modified nano-silica sol (10 of the emboss crystal, 5 parts of the chip-modified graphene complex, wetted dispersant Di High 2450.2 parts, thickener carboxymethylcellulose sodium 0.2 parts, 0.5 parts of the defoamer mineral oil silicon group, the leveling agent BYK37203 parts, and 35 deionized water.

[0032] The preparation process of the above modified nano silica sol emulsion includes the steps of:

[0033] 3-methacryloxypropyltrimethoxysilane modified agent and water-based surfactant and water were slowly added to nano silica sol, and 3-methylpropyloxypropyltrimethylammel group The addition amount of the silane modifier was 1.5 wt% of the nanocarcosilic silicon solution, and then stirred for 10 hours until the appearance was obtained as a low viscosity emulsion of the milky white translucent, that is, the modified nano silica sol. Emulsion.

[0034] The preparation process of...

Embodiment 2

[0042] An inorganic weather-resistant concrete protective coating includes a component of a weight of 52 copies of the modified nano-silica sol (9 pieces of concave convex rod crystal, 4 servants), 4 parts of the chip-modified graphene complex, wetted dispersant Di High 2450.3 parts, thickener hydroxyethyl cellulose, 0.4 emulsifiables of ablated agent aliphatic hydrocarbons, 32 parts of graft by K37202, and 32 deionized water.

[0043] The preparation process of the above modified nano silica sol emulsion includes the steps of:

[0044] 3-methacryloxypropyltrimethoxysilane modified agent and water-based surfactant and water were slowly added to nano silica sol, and 3-methylpropyloxypropyltrimethylammel group The addition amount of the silane modifier was 1.6% by weight of the nano silicon sol. After the addition was completed, stirring was continued for 10 hours until the appearance was a low viscosity emulsion of the milky white translucent low viscosity emulsion, that is, the mo...

Embodiment 3

[0053] Provides an inorganic weather-resistant concrete protective coating, including a component of the following weight: 68 modified nano silica sol emulsions, 9 concave convex rods, 4 parts of the chip-modified graphene complex, wetted dispersant Di High 2450.4 parts, thickener polyvinylpyrrolidone, 0.4 dispensing agent polyether organic compounds, grant byk37202 parts, and 28 deionized water.

[0054] The preparation process of the above modified nano silica sol emulsion includes the steps of:

[0055] 3-methacryloxypropyltrimethoxysilane modified agent and water-based surfactant and water were slowly added to nano silica sol, and 3-methylpropyloxypropyltrimethylammel group The addition amount of the silane modifier was 1.7% by weight of the nanocarcine sol. After the addition was completed, stirring was continued for 10 hours until the appearance was obtained as a milky white translucent low viscosity emulsion, that is, the modified nano silica sol. Emulsion.

[0056] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com