Composite phase change powder material for selective laser sintering as well as preparation method and application of composite phase change powder material

A composite phase change and powder material technology, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of large thermal cycle loss, uneven particle size distribution, and low powder sphericity of thermal management components, and achieves a reduction in Van der Waals force, high latent heat, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

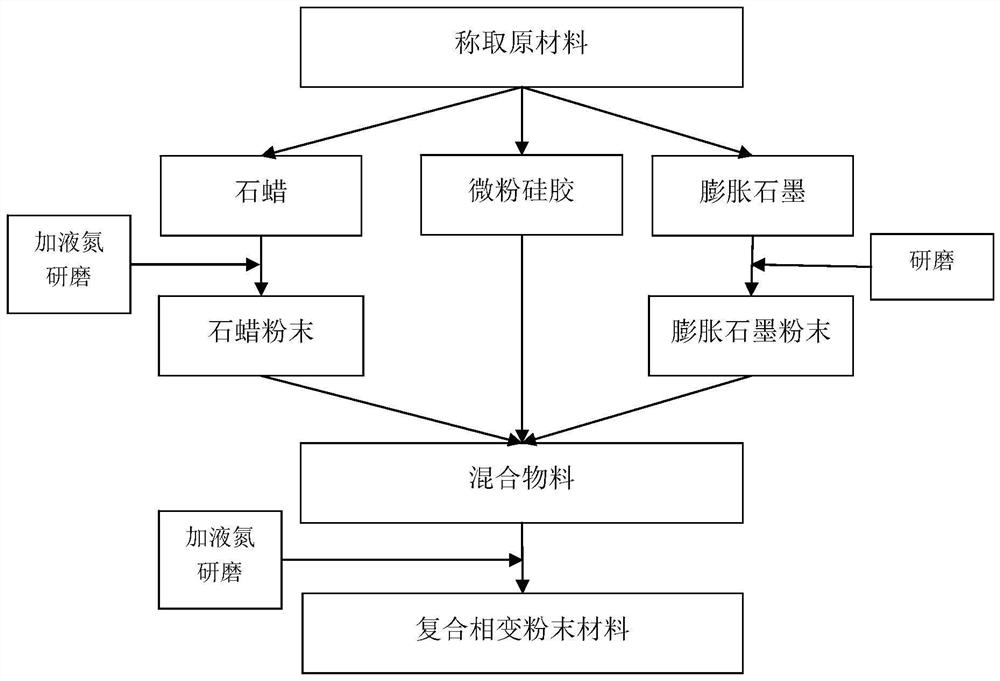

Method used

Image

Examples

Embodiment 1

[0039] A composite phase change powder material for selective laser sintering, the composite phase change powder material includes the following raw material components in parts by mass:

[0040] 80 parts of paraffin,

[0041] 15 parts of expanded graphite,

[0042] Micropowder silica gel 5 parts.

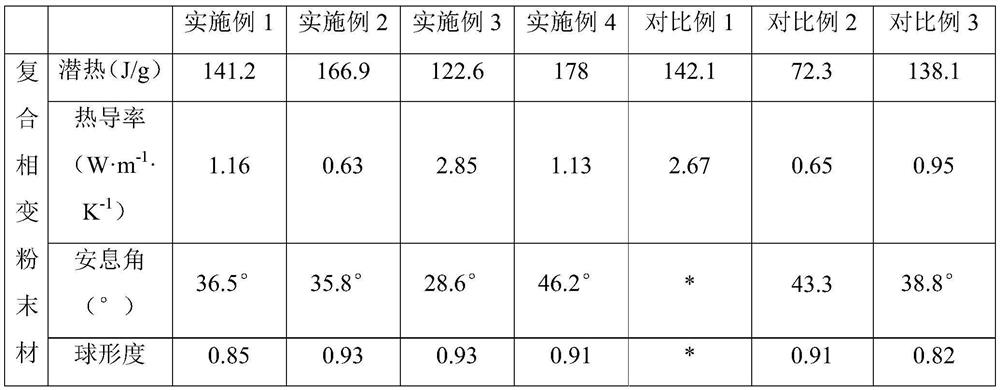

[0043] In this embodiment, the particle size of the composite phase change powder material is 50 μm˜150 μm, and the sphericity is 0.85.

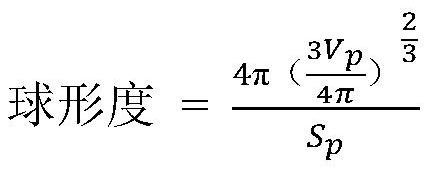

[0044] The calculation formula of sphericity is as follows:

[0045]

[0046] Among them, V p is the particle volume, S p is the particle surface area.

[0047] A method for preparing a composite phase-change powder material for selective laser sintering in the above-mentioned embodiment, comprising the following steps:

[0048] (1) According to the mass ratio of 80:15:5 (calculated as 100 parts), respectively weigh paraffin wax, expanded graphite, and micropowdered silica gel.

[0049] (2) Put the weighed solid paraffin (melting point ...

Embodiment 2

[0053] A composite phase change powder material for selective laser sintering, the composite phase change powder material includes the following raw material components in parts by mass:

[0054] 85 parts of paraffin,

[0055] 10 parts of expanded graphite,

[0056] Micropowder silica gel 5 parts.

[0057] In this embodiment, the particle size of the composite phase-change powder material is 50 μm˜150 μm, and the sphericity is 0.93.

[0058] A method for preparing a composite phase-change powder material for selective laser sintering in the above-mentioned embodiment, comprising the following steps:

[0059] (1) According to the mass ratio of 85:10:5 (calculated as 100 parts), respectively weigh paraffin wax, expanded graphite, and micropowdered silica gel.

[0060] (2) Put the weighed solid paraffin (melting point is 56°C) into a planetary ball mill, pour -196°C liquid nitrogen into the ball mill tank to submerge the paraffin, and after the paraffin hardens, add manganese ...

Embodiment 3

[0064] A method for preparing a composite phase-change powder material for selective laser sintering is basically the same as in Example 2, the only difference being that in Example 3, the composite phase-change powder material includes the following raw material components in parts by mass:

[0065] 70 parts of paraffin,

[0066] 20 parts of expanded graphite,

[0067] Micronized silica gel 10 parts.

[0068] The particle size of the composite phase-change powder material prepared in Example 3 is 50 μm-150 μm, and the sphericity is 0.93.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap