Novel assembly type heat preservation externally-hung wallboard

An external wall panel and assembly technology, applied in the direction of thermal insulation, building types, protected buildings/shelters, etc., can solve the problem of failure of wall panels and connection nodes, failure to take into account mechanics, thermal engineering, earthquake resistance, durability, Easy to assemble, imperfect structural system of prefabricated thermal insulation external wall panels, etc., to achieve high ductility and toughness, light toughness, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

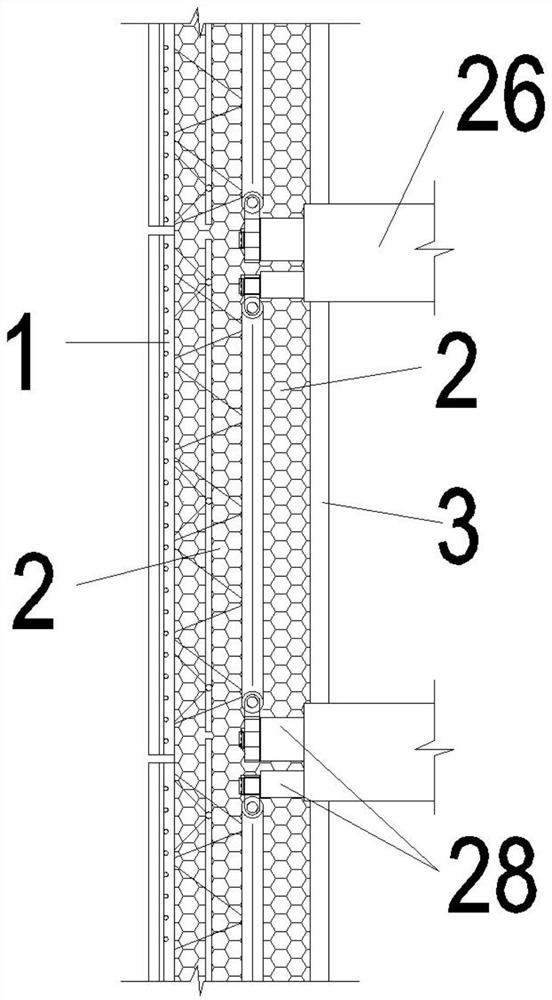

[0050] Specific implementation mode 1: This implementation mode records a new type of prefabricated thermal insulation external wallboard, such as figure 1 As shown, the wall panel includes a structural frame 1, an insulating layer 2 and an inner panel 3; the insulating layer 2 is located between the structural frame 1 and the inner panel 3, and the insulating layer 2 is fixed and restrained by the structural frame 1; The structural frame 1 and the inner panel 3 with the insulation layer 2 are transported, hoisted and assembled separately;

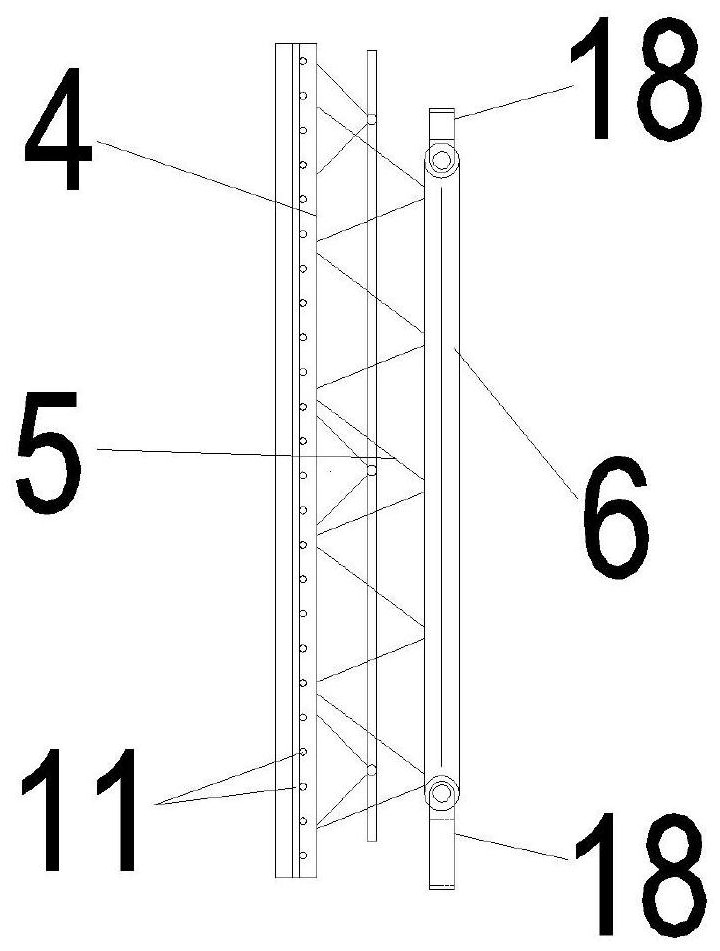

[0051] Such as figure 2 As shown, the structural frame 1 includes a main board 4, a plurality of main trusses 5 and a plurality of main rods 6, and the main board 4 is connected to each main rod 6 through a plurality of main trusses 5;

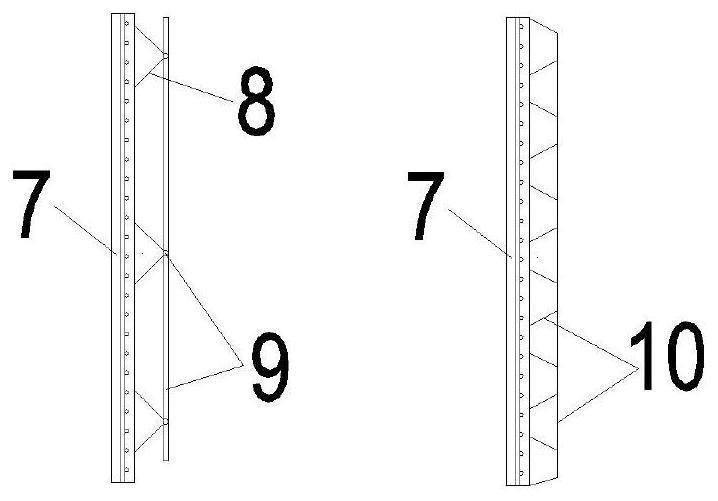

[0052] Such as image 3 As shown, the main board 4 includes a prestressed concrete slab 7, a plurality of steel trusses 8 and a plurality of steel pipe concrete 9, or includes a prestressed concrete sla...

specific Embodiment approach 2

[0059] Specific embodiment two: a new type of prefabricated thermal insulation external wall panel described in specific embodiment one, the specific position 31 of the steel wire in the steel tube concrete is: on the diameter perpendicular to the prestressed concrete slab 7, away from the prestressed concrete slab Two-thirds of 7. And the ribs 32 are welded on the surface of the steel wire 13, the distance between the ribs 32 is 10-20cm, the ribs 32 are dense in the middle of the steel wire 13, and the ribs 32 in both ends are sparse.

specific Embodiment approach 3

[0060] Embodiment 3: In Embodiment 1, a new type of prefabricated thermal insulation wall panel, the winding angle of GFRP in the main truss 5 is 20-30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com