Copper core-kovar alloy composite wire for electronic packaging

An electronic packaging and composite wire technology, applied in metal/alloy conductors, cable/conductor manufacturing, conductors, etc., can solve the problems of low bonding strength and air holes, and achieve low cost, high production efficiency, and air tightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

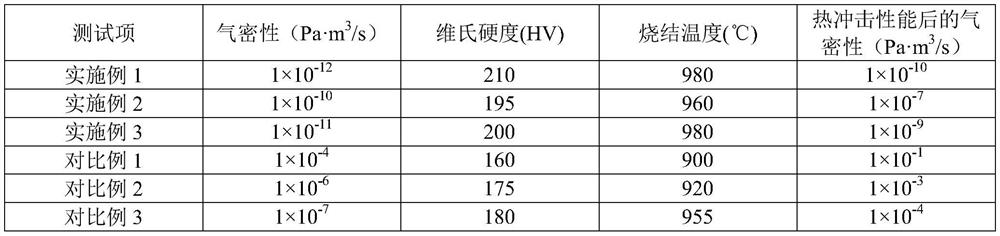

Embodiment 1

[0044] A copper core kovar alloy composite wire for electronic packaging is prepared according to the following steps:

[0045] (1) Clean and dry the steel pipe, put it into a vacuum melting furnace, and keep a high vacuum state in the furnace, with a vacuum degree of 5x10 -4 Pa, the steel pipe is in an upright state in the furnace, and the steel pipe is Kovar 4J49 alloy steel;

[0046] (2) placing the cathode copper into a graphite crucible for heating and melting to form copper liquid;

[0047] (3) Preheat the steel pipe dried in step (1) to 600°C and keep it warm for 2 hours;

[0048] (4) Refining the copper liquid obtained in step (2), pouring it into the steel pipe preheated in step (3) after refining, then cooling down to 300° C. with the furnace, taking out the furnace and cooling to room temperature to obtain a composite ingot;

[0049] (5) shaping the composite billet into an extruded billet;

[0050] (6) the extruded billet is placed in a 500-ton extruder, and ext...

Embodiment 2

[0054]A copper core kovar alloy composite wire for electronic packaging is prepared according to the following steps:

[0055] (1) Clean and dry the steel pipe, put it into a vacuum melting furnace, and keep a high vacuum state in the furnace, with a vacuum degree of 4x10 -3 Pa, the steel pipe is in an upright state in the furnace, and the steel pipe is Kovar 4J50 alloy steel;

[0056] (2) placing the cathode copper into a graphite crucible for heating and melting to form copper liquid;

[0057] (3) Preheat the steel pipe dried in step (1) to 600°C and keep it warm for 2 hours;

[0058] (4) Refining the copper liquid obtained in step (2), pouring it into the steel pipe preheated in step (3) after refining, then cooling down to 300° C. with the furnace, taking out the furnace and cooling to room temperature to obtain a composite ingot;

[0059] (5) shaping the composite billet into an extruded billet;

[0060] (6) the extruded billet is placed in a 500-ton extruder, and extr...

Embodiment 3

[0064] A copper core kovar alloy composite wire for electronic packaging is prepared according to the following steps:

[0065] (1) Clean and dry the steel pipe, put it into a vacuum melting furnace, and keep a high vacuum state in the furnace, with a vacuum degree of 3×10 -2 Pa, the steel pipe is in an upright state in the furnace, and the steel pipe is Kovar 4J33 alloy steel;

[0066] (2) placing the cathode copper into a graphite crucible for heating and melting to form copper liquid;

[0067] (3) Preheat the steel pipe dried in step (1) to 600°C and keep it warm for 2 hours;

[0068] (4) Refining the copper liquid obtained in step (2), pouring it into the steel pipe preheated in step (3) after refining, then cooling down to 300° C. with the furnace, taking out the furnace and cooling to room temperature to obtain a composite ingot;

[0069] (5) shaping the composite billet into an extruded billet;

[0070] (6) the extruded billet is placed in a 500-ton extruder, and ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com