Preparation method of iron-silicon magnetic powder core

A magnetic powder core and iron-silicon technology, which is applied in the field of preparation of iron-silicon magnetic powder cores, can solve the problems of poor binding ability between inorganic coating medium and magnetic powder particles, increase the complexity of the metal magnetic powder core process, and high brittleness, and achieve guaranteed performance. Effect of increasing effective permeability and reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

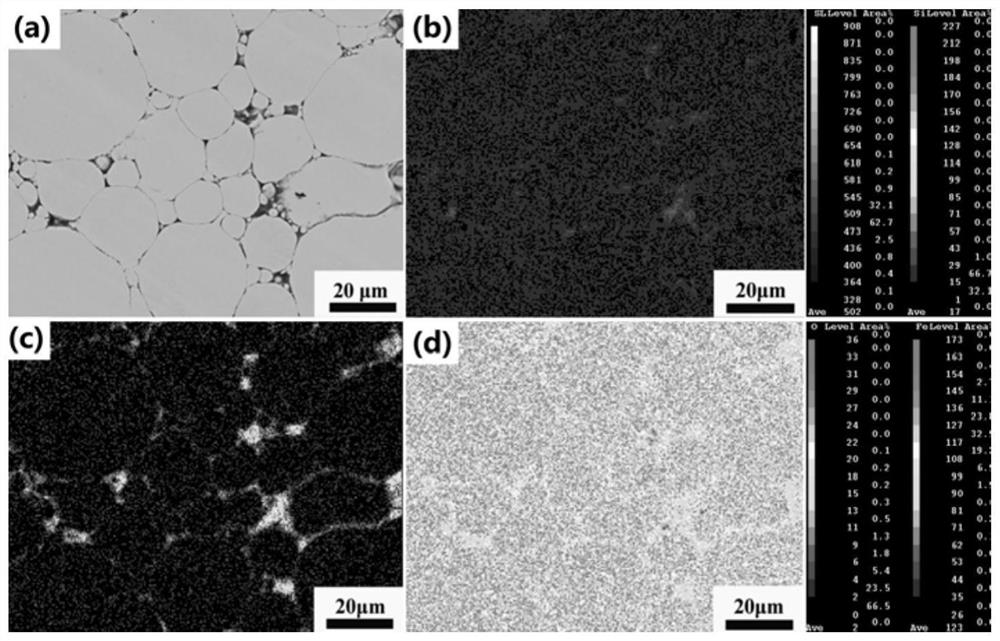

Image

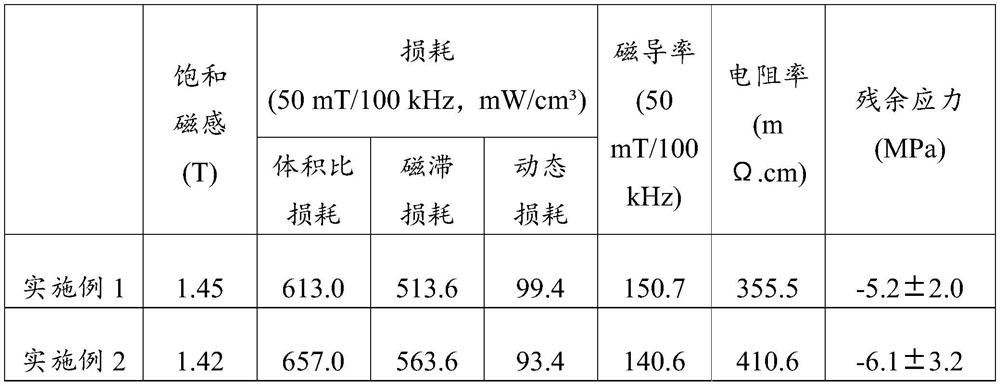

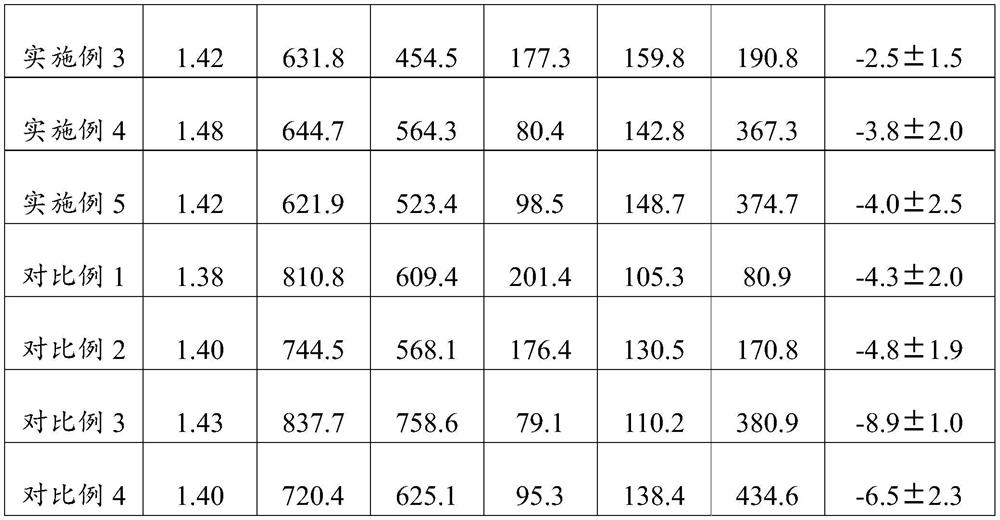

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing an iron-silicon magnetic powder core, comprising the following steps:

[0031] (1) The iron-silicon spherical powder is prepared by a gas atomization process, the parameters of the gas atomization process are: the atomization pressure is 6 MPa, and the atomization temperature is 1580 ° C; the particle size of the iron-silicon spherical powder is: D 10 = 12.7 μm, D 50 = 31.5 μm, D 90 =68.5 μm; In terms of mass fraction, the Si content in the iron-silicon spherical powder is 6.5% of the total mass;

[0032] (2) Add the iron-silicon spherical powder prepared in step (1) to the mixture of silicone resin and acetone and mix evenly, then ultrasonically stir until dry to obtain an insulating-coated composite magnetic powder; silicone resin, acetone and iron-silicon The mass ratio of the spherical powder is silicone resin: acetone: silicon spherical powder = 0.5:1:100;

[0033] (3) uniformly distribute the composite magnetic po...

Embodiment 2

[0036] This embodiment provides a method for preparing an iron-silicon magnetic powder core, comprising the following steps:

[0037](1) The iron-silicon spherical powder is prepared by a gas atomization process, the parameters of the gas atomization process are: the atomization pressure is 6 MPa, and the atomization temperature is 1580 ° C; the particle size of the iron-silicon spherical powder is: D 10 = 12.7 μm, D 50 = 31.5 μm, D 90 =68.5 μm; In terms of mass fraction, the Si content in the iron-silicon spherical powder is 6.5% of the total mass;

[0038] (2) Add the iron-silicon spherical powder prepared in step (1) to the mixed solution of silicone resin and organic solvent and mix evenly, then ultrasonically stir until dry to obtain an insulating-coated composite magnetic powder; silicone resin, organic solvent and The mass ratio of iron-silicon spherical powder is silicone resin:organic solvent:silicon spherical powder=1.0:1:100;

[0039] (3) uniformly distribute the...

Embodiment 3

[0042] This embodiment provides a method for preparing an iron-silicon magnetic powder core, comprising the following steps:

[0043] (1) The iron-silicon spherical powder is prepared by a gas atomization process, the parameters of the gas atomization process are: the atomization pressure is 6 MPa, and the atomization temperature is 1580 ° C; the particle size of the iron-silicon spherical powder is: D 10 = 12.7 μm, D 50 = 31.5 μm, D 90 =68.5 μm; In terms of mass fraction, the Si content in the iron-silicon spherical powder is 6.5% of the total mass;

[0044] (2) Add the iron-silicon spherical powder prepared in step (1) to the mixed solution of silicone resin and organic solvent and mix evenly, then ultrasonically stir until dry to obtain an insulating-coated composite magnetic powder; silicone resin, organic solvent and The mass ratio of iron-silicon spherical powder is silicone resin:organic solvent:silicon spherical powder=0.25:1:100;

[0045] (3) uniformly distribute t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com