Simple heat insulation house plant factory coupled with photovoltaic power generation system and construction method

A technology of photovoltaic power generation system and thermal insulation room, which is applied in the direction of photovoltaic power generation, botany equipment and methods, gardening methods, etc. It can solve the problems of changing the nature of the land, the area of photovoltaic laying can not be fully covered, and the lack of thermal insulation facilities, etc., to reduce construction costs , Ensure energy-saving and efficient operation, and solve the effect of local consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

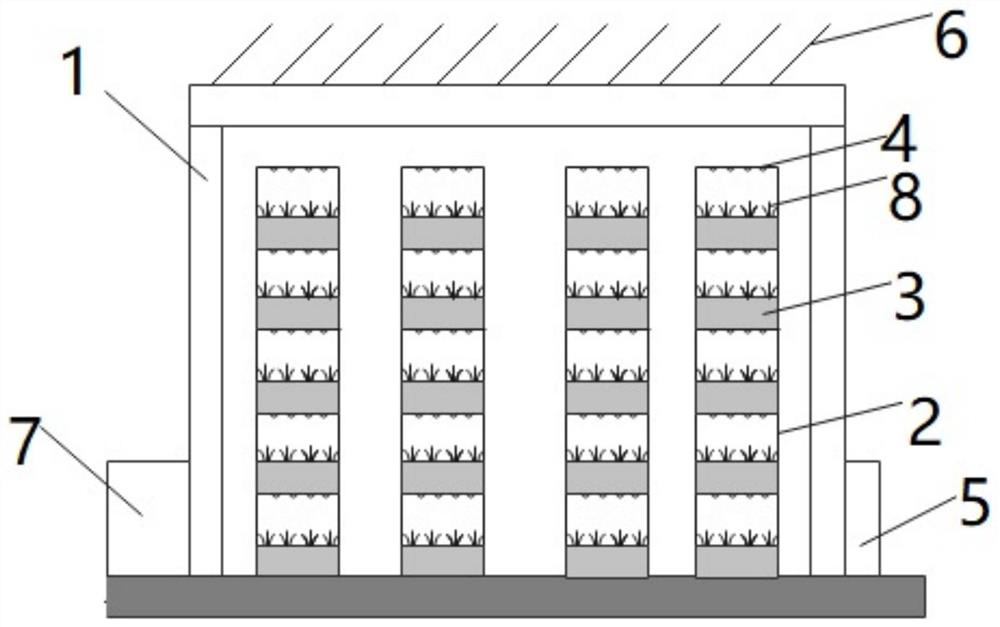

[0035] Such as figure 1 , in view of this, this embodiment proposes a plant factory with a simple thermal insulation room coupled with a photovoltaic power generation system, including a plant 1, a planting frame 2 arranged in the plant 1, a planting tray 3, and a full artificial light LED lighting lamp 4; Several plates 3 are set on the planting frame 2; full artificial light LED lighting lamps 4 are set on the planting frame 2, located above the planting plate 3;

[0036] New energy power generation and power supply device; power generation and power supply to plant factories;

[0037] A hydroponic solution circulation device 5; wherein the hydroponic solution circulation device 5 provides a hydroponic solution for the plants 8 in the planting tray 3.

[0038] This embodiment can be specifically understood as: the factory building 1 is set on the agricultural land, and several planting frames 2 arranged in parallel are arranged in the factory building 1, and several plantin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com