Modified layered aluminosilicate for improving quality of breeding duck eggs as well as preparation method and application of modified layered aluminosilicate

A technology of layered aluminosilicate and aluminosilicate, which is applied in application, chemical instruments and methods, silicon compounds, etc., can solve the problems of inability to adsorb hydrophobic substances and unstable adsorption, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

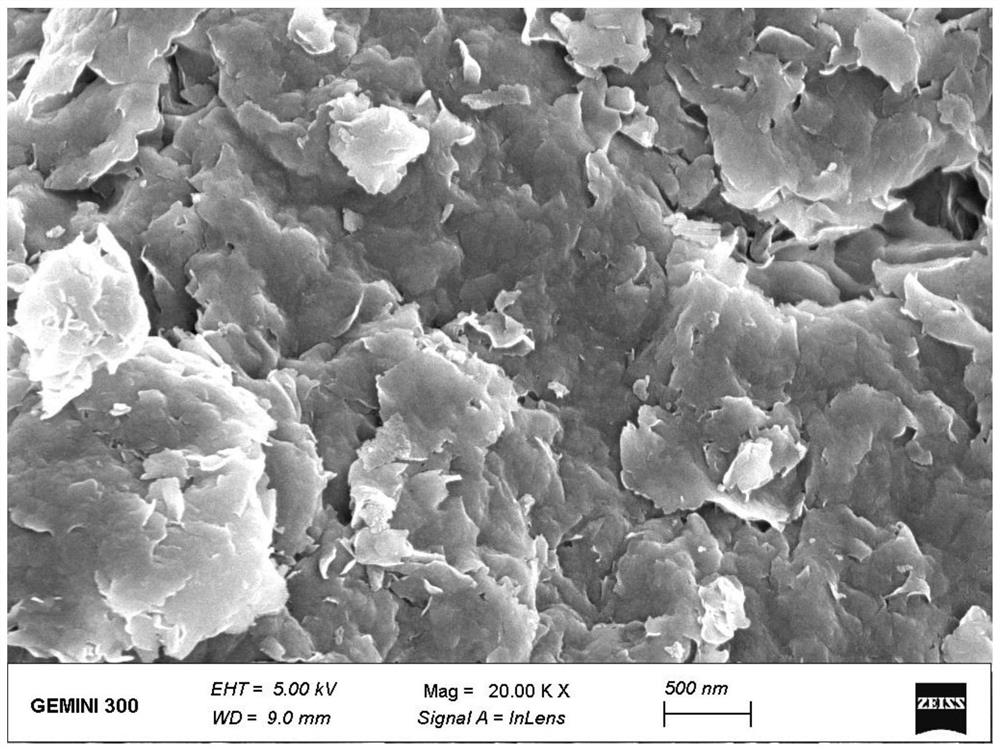

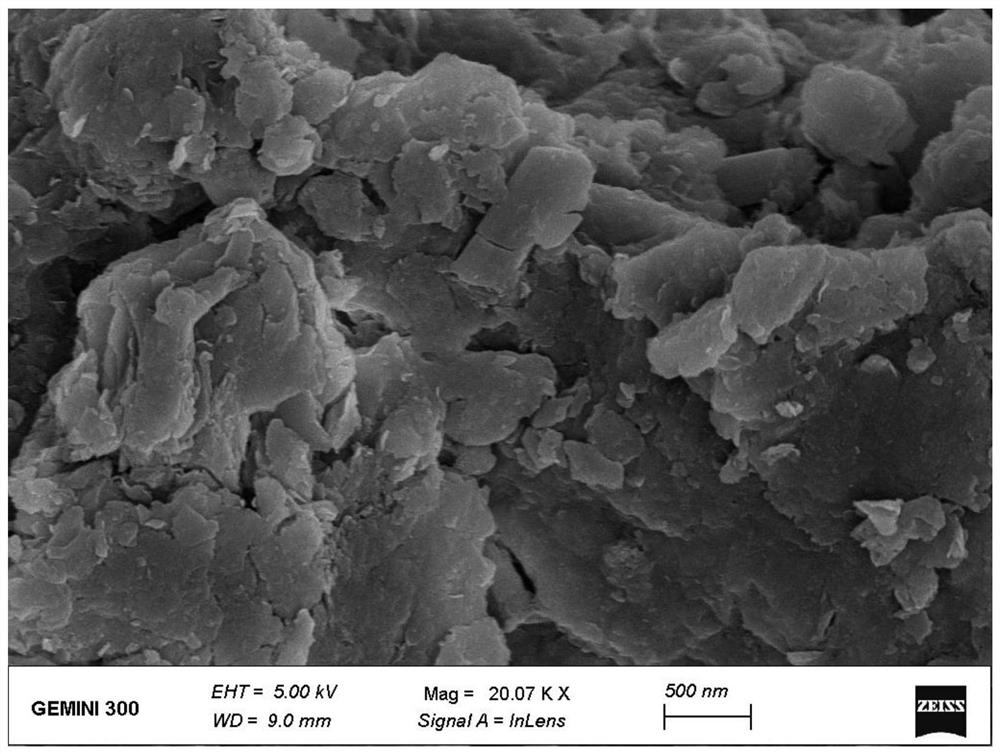

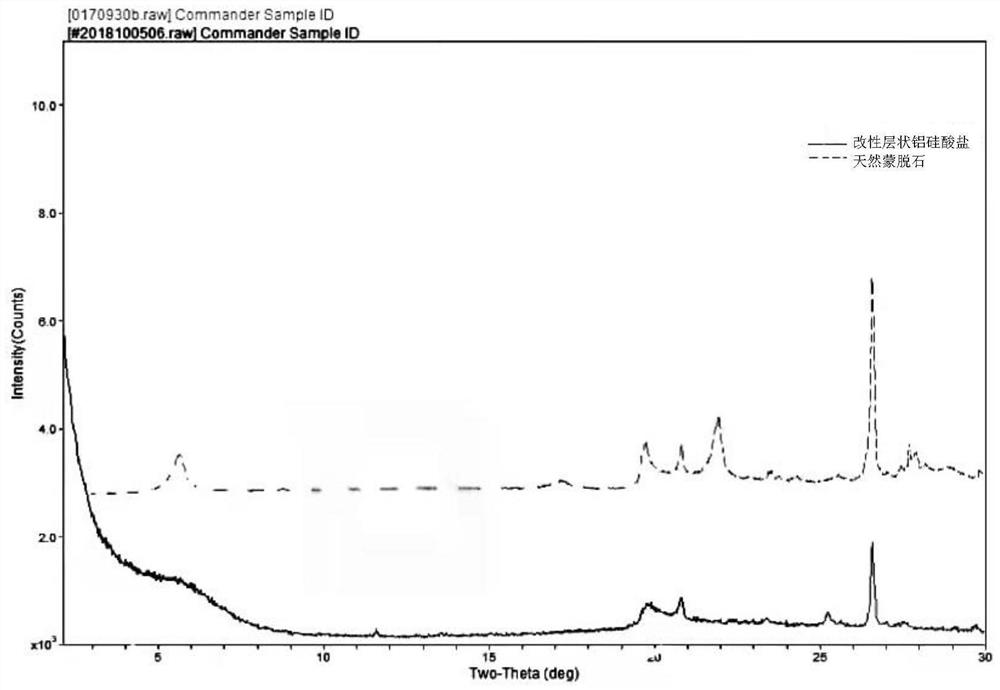

[0026] Preparation of Modified Layered Aluminosilicate

[0027] (1) Separation and purification: After crushing and rolling 1kg of montmorillonite raw ore for 15 minutes, add 3.5L hydrogen peroxide to soak for 300 minutes to remove organic matter and other harmful impurities, and then carry out suction filtration and sieving to remove large particles of impurities; use deionized water After rinsing once, add deionized water in proportion to the system, use strong stirring equipment, and cooperate with a custom-made stirring tank to make a slurry with a solid content of 10%, centrifuge it through a high-speed horizontal centrifuge at 10,000r / min for 10min, separate and Remove the associated impurities of the raw ore to obtain a purified raw pulp with a montmorillonite content of more than 90%;

[0028] (2) Adjust the pH value: add 350ml of hydrochloric acid solution to every 1kg of the purified raw pulp, acidify in a closed chamber at 60°C for 2 hours, then add 120g of calcium ...

Embodiment 2

[0034] Preparation of Modified Layered Aluminosilicate

[0035] (1) Separation and purification: After crushing and rolling 1kg of montmorillonite raw ore for 20 minutes, add 3.5L hydrogen peroxide to soak for 40 minutes to remove organic matter and other harmful impurities, and then carry out suction filtration and sieving to remove large particles of impurities; use deionized water After rinsing once, add deionized water in proportion to the system, use strong stirring equipment, cooperate with custom-made stirring tanks, make a slurry with a solid content of 10%, pass through a high-speed horizontal centrifuge, centrifuge at 12000r / min for 15min, separate and Remove the associated impurities of the raw ore to obtain a purified raw pulp with a montmorillonite content of more than 90%;

[0036] (2) Adjust the pH value: add 380ml of hydrochloric acid solution to every 1kg of the purified raw pulp, acidify in a closed state at 65°C for 2.5 hours, then add 130g of calcium carbon...

Embodiment 3

[0040] Preparation of Modified Layered Aluminosilicate

[0041] (1) Separation and purification: After crushing and rolling 1kg of montmorillonite raw ore for 18 minutes, add 3.5L hydrogen peroxide to soak for 35 minutes to remove organic matter and other harmful impurities, and then carry out suction filtration and sieving to remove large particles of impurities; use deionized water After rinsing once, add deionized water in proportion to the system, use strong stirring equipment, and cooperate with a custom-made stirring tank to make a slurry with a solid content of 10%, centrifuge through a high-speed horizontal centrifuge at 11000r / min for 12min, separate and Remove the associated impurities of the raw ore to obtain a purified raw pulp with a montmorillonite content of more than 90%;

[0042] (2) Adjust the pH value: add 365ml of hydrochloric acid solution to every 1kg of purified raw pulp, acidify at 625°C for 2 hours, then add 150g of calcium carbonate to neutralize, cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com