Magnetic/high-infrared-emissivity composite material, preparation method and application thereof

A technology of infrared emissivity and composite materials, applied in the field of magnetic/high infrared emissivity composite materials and their preparation, to achieve the effects of increasing surface roughness, large specific surface area, and improving infrared radiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

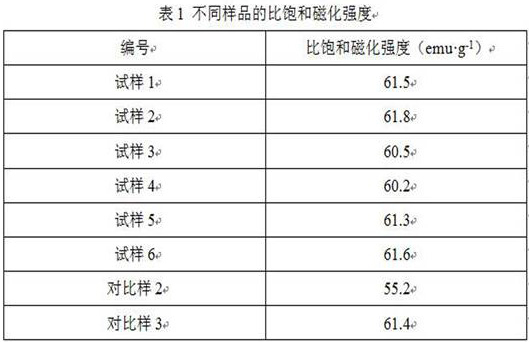

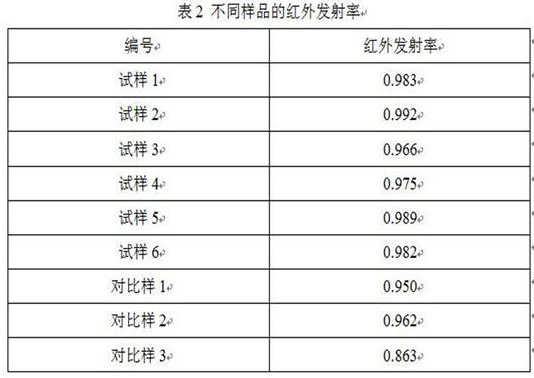

Examples

Embodiment 1

[0031] A magnetic / high infrared emissivity composite material (with modified nano-Fe 3 o 4 is a magnetic nanomaterial, graphene is an infrared radiation material), and is prepared through the following steps:

[0032] (1) In a beaker, put 10g Fe(NO 3 ) 3 9H 2 Dissolve O in 20ml of absolute ethanol. After it is completely dissolved, add 9.8g of urea and stir thoroughly. After a few minutes, a light blue precipitate gradually forms at the bottom of the beaker. After stirring for 1 hour, wash with ethanol, filter under normal pressure, and dry naturally After that, a light green precipitate iron-urea precursor was obtained. Then put 1 g of iron-urea precursor into the autoclave and heat at 250 °C for 2 h to prepare nano-Fe 3 o 4 .

[0033] (2) Add 4g nanometer Fe 3 o 4 , 40ml of xylene and 1.2ml of distilled water were sequentially added into a 250ml three-neck flask, ultrasonically dispersed for 30min to form a magnetic fluid. Then add 15g of 3-chloropropyltriethoxysil...

Embodiment 2

[0036] A magnetic / high infrared emissivity composite material (with modified nano-Fe 3 o 4 For magnetic nanomaterials, carbon nanotubes for infrared radiation materials), prepared by the following steps:

[0037] (1) In a beaker, put 10g Fe(NO 3 ) 3 9H 2 Dissolve O in 20ml of absolute ethanol. After it is completely dissolved, add 9.8g of urea and stir thoroughly. After a few minutes, a light blue precipitate gradually forms at the bottom of the beaker. After stirring for 1 hour, wash with ethanol, filter under normal pressure, and dry naturally After that, a light green precipitate iron-urea precursor was obtained. Then put 1 g of iron-urea precursor into the autoclave and heat at 250 °C for 2 h to prepare nano-Fe 3 o 4 .

[0038] (2) Add 4g nanometer Fe 3 o 4 , 40ml of xylene and 1.2ml of distilled water were sequentially added into a 250ml three-neck flask, ultrasonically dispersed and stirred for 30min to form a magnetic fluid. Then add 15g of 3-chloropropyltriet...

Embodiment 3

[0041] A magnetic / high infrared emissivity composite material (modified nano-TiO 2 is a magnetic nanomaterial, graphene is an infrared radiation material), and is prepared through the following steps:

[0042] (1) Take 2mol of TiCl in an ice-water bath with strong stirring 4 Slowly drop into 100ml of distilled water, set the volume to 2mol / L stock solution, take 5ml stock solution and dilute to 1mol / L, slowly add 50mol / L sodium hydroxide solution under stirring condition, keep 30℃ for reaction, Nano-TiO 2 Precursor. Nano TiO 2 The precursor was placed in a high-pressure reactor and reacted at 130 °C for 5 h, the product was separated by filtration, and then dried in a drying oven at 50 °C for 24 h to obtain nano-TiO 2 powder.

[0043] (2) 4g nano-TiO 2 The powder, 40ml of xylene and 1.2ml of distilled water were sequentially added into a 250ml three-neck flask, ultrasonically dispersed and stirred for 30min to form a magnetic fluid. Then add 15g of 3-chloropropyltrietho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com