Temperature-resistant polymer based on low-pyruvate xanthan gum and application of temperature-resistant polymer

A technology of pyruvate-based yellow and polymer, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high complex cost, high reversion rate, and energy consumption, and achieve simple process operation and improved stability Good performance and thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 A temperature-resistant type xanthan gum polymer, comprising the following components and mass fraction thereof:

[0045] Low Pyruvate Xanthan Gum 72%

[0046] Stabilizer 18%

[0047] Protectant 10%

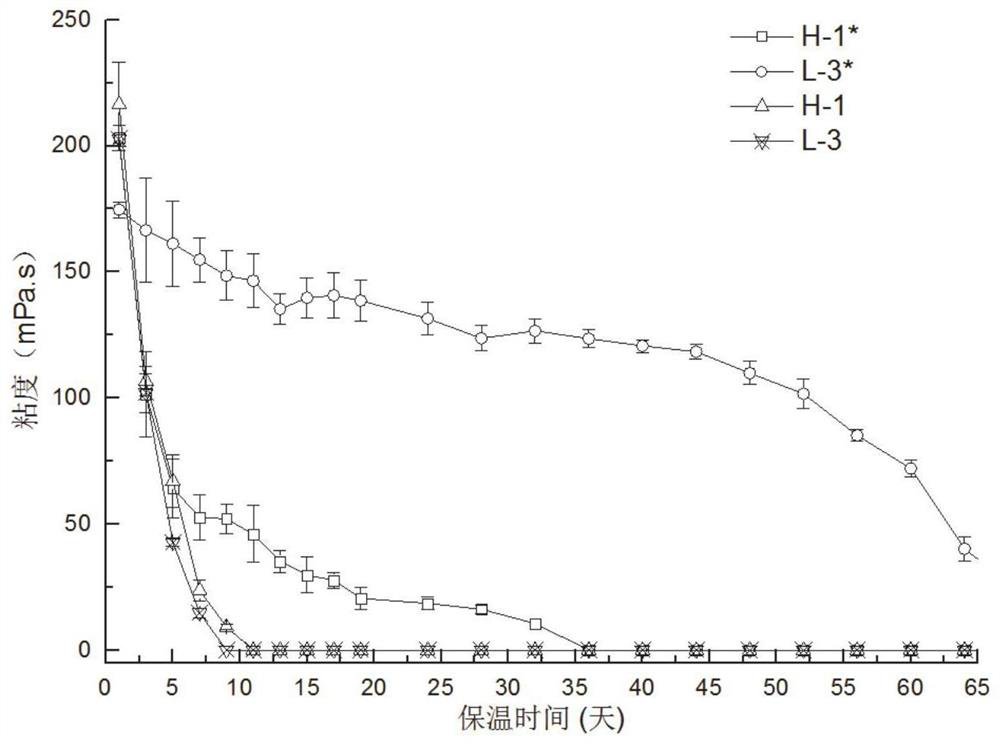

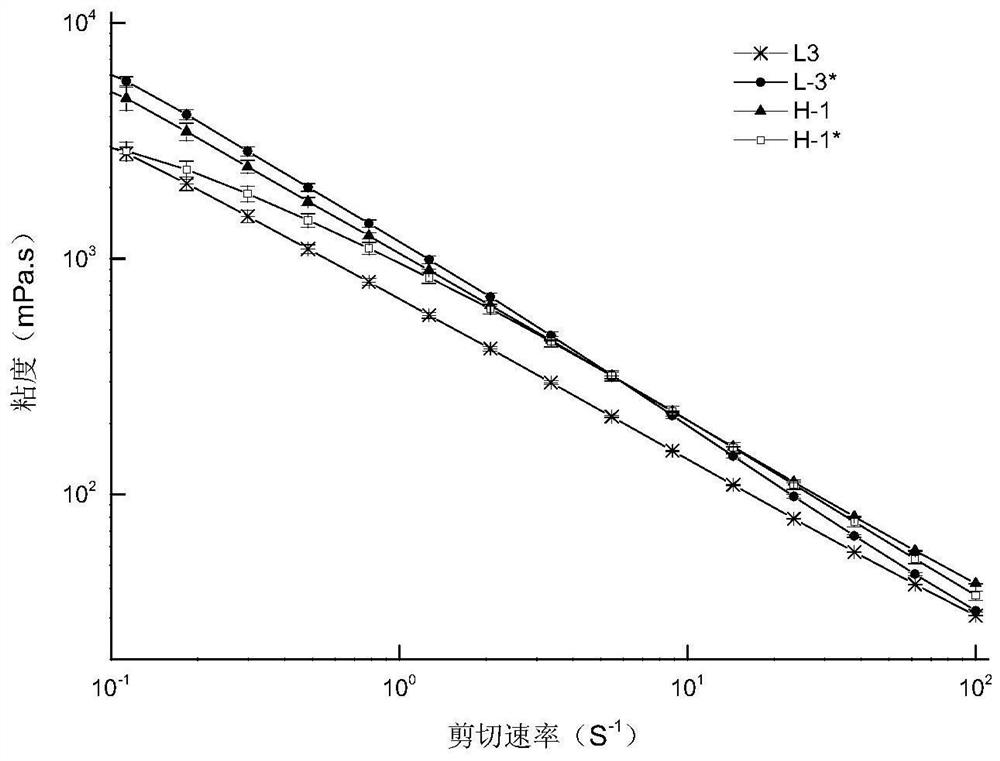

[0048] The pyruvate group content of the low-pyruvate group xanthan gum product (L-3) is 0.087%; the stabilizer is succinaldehyde; and the protecting agent is sodium sulfite.

[0049] The preparation method of described temperature-resistant type xanthan gum polymer (L-3*) is: take low-pyruvate group xanthan gum (L-3) 720g, glyoxal 180g, sodium sulfite 100g respectively, fully mix, Obtain 1000 g of temperature-resistant xanthan gum temperature-resistant polymer (L-3*), and seal it for future use.

Embodiment 2

[0050] Embodiment 2 A temperature-resistant xanthan gum polymer, comprising the following components and mass fraction thereof:

[0051] Low Pyruvate Xanthan Gum 60%

[0052] Stabilizer 20%

[0053] Protectant 20%

[0054] The pyruvate group content of the low-pyruvate-group xanthan gum product (L-3-2) is 0.057%; the stabilizer is succinic acid; and the protecting agent is sodium thiosulfate.

[0055] The preparation method of the temperature-resistant xanthan gum polymer (L-3-2*) is: respectively weigh 720g of low-pyruvate xanthan gum (L-3-2), 180g of oxalic acid, thiosulfuric acid Sodium 100g, fully mix evenly, obtain temperature resistant type xanthan gum polymer (L-3-2*) 1000g, seal up for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com