Super-hydrophobic conductive leather and preparation method thereof

A super-hydrophobic, leather-based technology, applied in special leather manufacturing, small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather skin/fur chemical treatment, etc., can solve the problem of electrical conductivity and electronic sensing Stability and other issues, to achieve the effect of easy realization, excellent conductivity and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

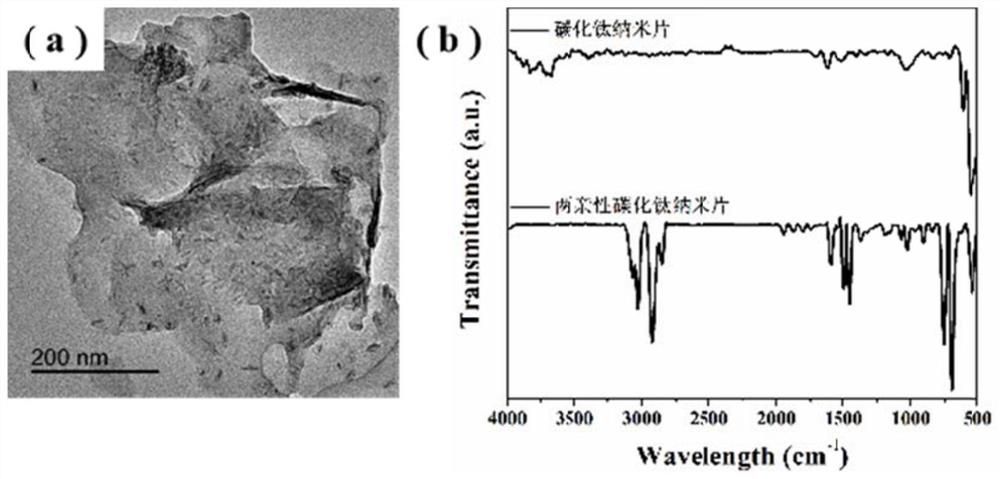

[0043]A preparation method of amphiphilic titanium carbide nanosheets, comprising the steps of:

[0044] (1) Dissolve 2.5g of polyvinylpyrrolidone in a mixture of 75mL of absolute ethanol and 21mL of deionized water, stir at 130rpm at room temperature, then add 12g of styrene and 0.19g of azobisiso Butyronitrile, stirred for 35 minutes, incubated at 85°C for 17 hours, centrifuged, washed, and vacuum-dried at 45°C for 5 hours to obtain polystyrene microspheres.

[0045] (2) Add 0.32g of polystyrene microspheres into 120mL of deionized water, ultrasonically disperse for 22min, then add 165mL of titanium carbide aqueous dispersion with a concentration of 1.1mg / mL, stir at 400rpm for 5h at room temperature, and centrifuge the product , washed, and dried in vacuum at 30° C. for 5 hours to obtain polystyrene@titanium carbide microspheres.

[0046] (3) Add 0.4g polystyrene@titanium carbide microspheres into 35mL tetrahydrofuran, stir magnetically at 51°C and 410rpm for 35h, centrifu...

Embodiment 2

[0050] A preparation method of amphiphilic titanium carbide nanosheets, comprising the steps of:

[0051] (1) Dissolve 3.3g of polyvinylpyrrolidone in a mixture of 82mL of absolute ethanol and 10mL of deionized water, stir at 100rpm at room temperature, then add 18g of styrene and 0.15g of azobisiso Butyronitrile, stirred for 50 minutes, incubated at 81°C for 20 hours, centrifuged, washed, and vacuum-dried at 50°C for 4 hours to obtain polystyrene microspheres.

[0052] (2) Add 0.25g of polystyrene microspheres into 150mL of deionized water, ultrasonically disperse for 34min, then add 190mL of titanium carbide aqueous dispersion with a concentration of 0.9mg / mL, stir at 310rpm at room temperature for 8h, and centrifuge the product , washed, and dried in vacuum at 55° C. for 7 hours to obtain polystyrene@titanium carbide microspheres.

[0053] (3) Add 0.3g polystyrene@titanium carbide microspheres into 60mL N'N'-dimethylformamide, stir magnetically at 35°C and 500rpm for 26h, ...

Embodiment 3

[0057] A preparation method of amphiphilic titanium carbide nanosheets, comprising the steps of:

[0058] (1) Dissolve 2.7g of polyvinylpyrrolidone in a mixture of 78mL of absolute ethanol and 25mL of deionized water, stir at 140rpm at room temperature, then add 15g of styrene and 0.20g of azobisiso Butyronitrile, stirred for 40 minutes, incubated at 70°C for 13 hours, centrifuged, washed, and vacuum-dried at 30°C for 6 hours to obtain polystyrene microspheres.

[0059] (2) Add 0.43g of polystyrene microspheres to 80mL of deionized water, ultrasonically disperse for 40min, then add 220mL of titanium carbide aqueous dispersion with a concentration of 1.2mg / mL, stir at 370rpm at room temperature for 6h, and centrifuge the product , washed, and dried in vacuum at 50° C. for 8 hours to obtain polystyrene@titanium carbide microspheres.

[0060] (3) Add 0.5 g of polystyrene@titanium carbide microspheres into 45 mL of acetone, stir magnetically at 55 °C and 260 rpm for 37 h, centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com