Finishing agent with antibacterial and anti-ultraviolet properties and method for finishing cotton fabric by adopting finishing agent

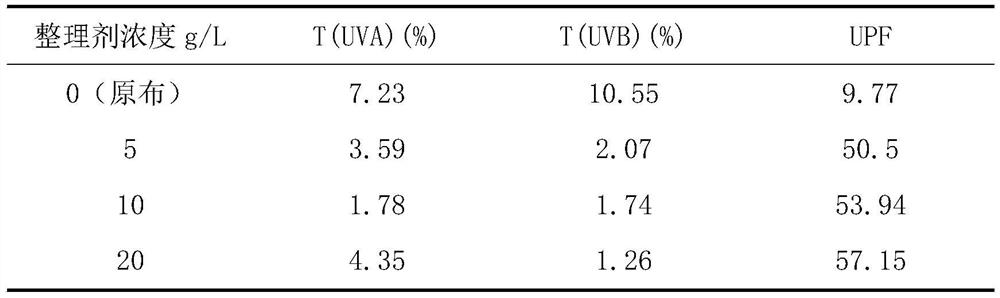

A finishing agent and anti-ultraviolet technology, applied in the textile industry, can solve the problems of single anti-ultraviolet performance, complex process, single antibacterial property, etc., and achieve the effect of excellent anti-ultraviolet performance and antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

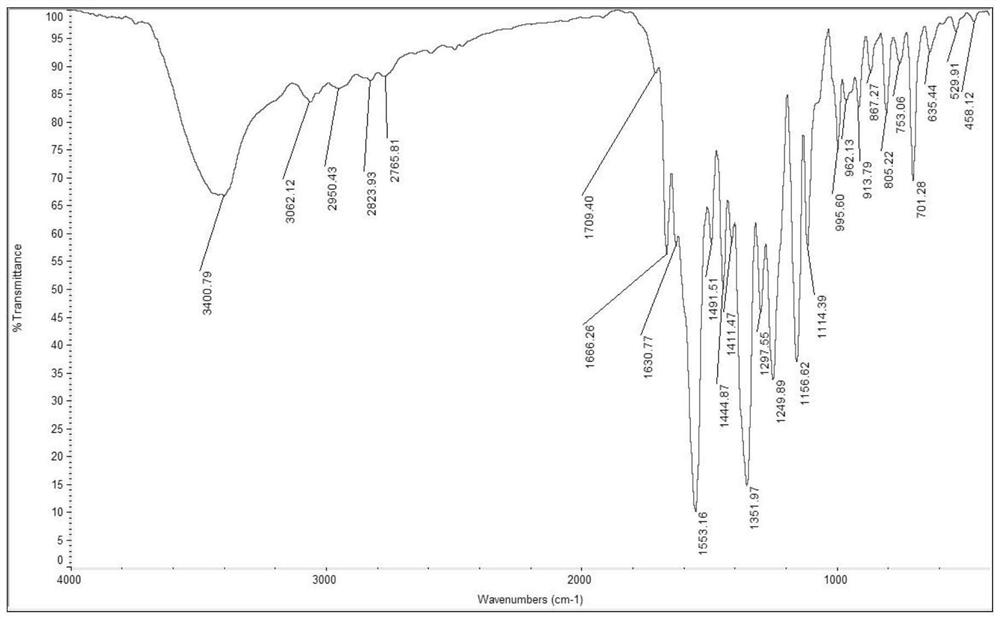

Image

Examples

Embodiment 1

[0025] A finishing agent with antibacterial and anti-ultraviolet properties, prepared by the following steps:

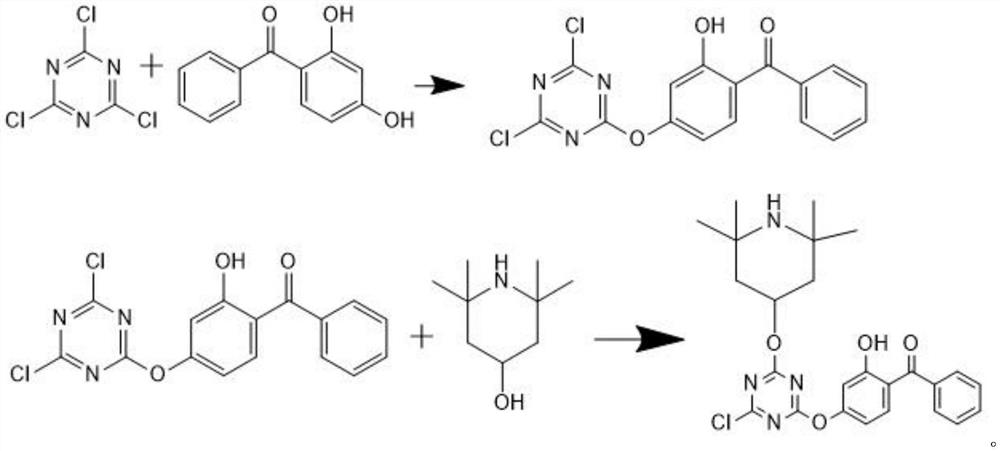

[0026] (1) Add 3.69g of cyanuric chloride (0.02mol) into 30mL of acetone, stir and dissolve to obtain a cyanuric chloride solution, use an ice bath to reduce the temperature of the cyanuric chloride solution to 0-5°C, and set aside ;

[0027] (2) Add 4.284g of 2,4-dihydroxybenzophenone (0.02mol) into 20mL of acetone, stir and dissolve to obtain 2,4-dihydroxybenzophenone solution;

[0028] (3) Measure 0.80g (0.02mol) of sodium hydroxide, add 30ml of distilled water to dissolve it, and obtain sodium hydroxide solution (as an acid-binding agent). The 2,4-dihydroxydiphenyl The ketone solution and the sodium hydroxide solution are mixed and stirred evenly, and then added dropwise to the cyanuric chloride solution in step (1). After the dropwise addition is completed, the temperature of the reaction solution is controlled to be 0-5° C. Control the pH of the reaction solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com