Modified sodium ion battery cobalt-free positive electrode material, preparation method thereof, and sodium ion battery

A technology for sodium-ion batteries and positive electrode materials, applied in battery electrodes, active material electrodes, positive electrodes, etc., can solve the problems of poor structural stability, high cost of positive electrode materials, long-term cycle stability and poor rate performance, etc. Increase, improve capacity and rate performance, improve the effect of long-term cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] As described in the background technology, to solve the problems of high cost and poor structural stability of the existing anode materials for sodium-ion batteries, which lead to the problems of long-term cycle stability and poor rate performance. In order to solve the above technical problems, the application provides a method for preparing a cobalt-free cathode material for a modified sodium-ion battery. The preparation method for a cobalt-free cathode material for a modified sodium-ion battery includes: The dopant is subjected to the first sintering treatment to obtain the first sintered product, wherein the dopant can be represented by the following chemical formula: M c D. d , wherein the M element is selected from one of the elements in Group IA, Group IIA, Group IIIA, Group IIIB, Group IVB, Group VB or Group VIB, and the element D is selected from Group IIIA, Group III One of the elements in Group VA or Group VIIA.

[0023]Through the above-mentioned first sin...

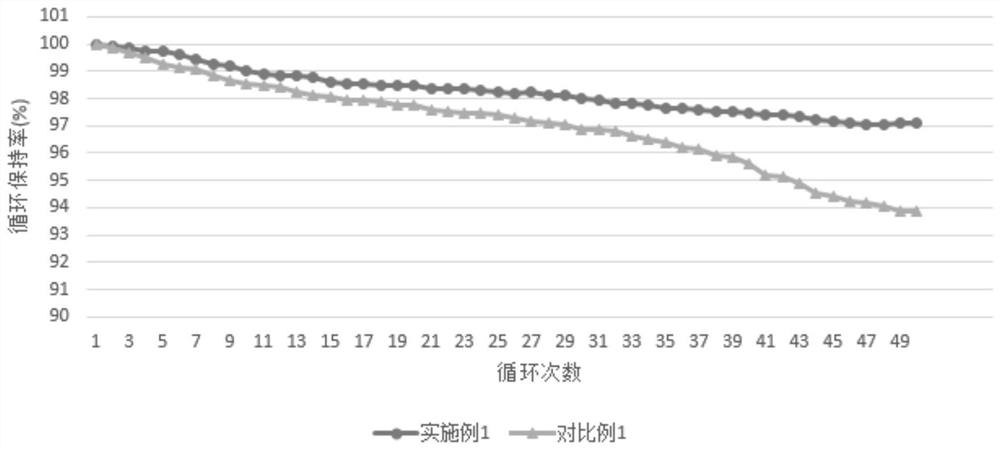

Embodiment 1

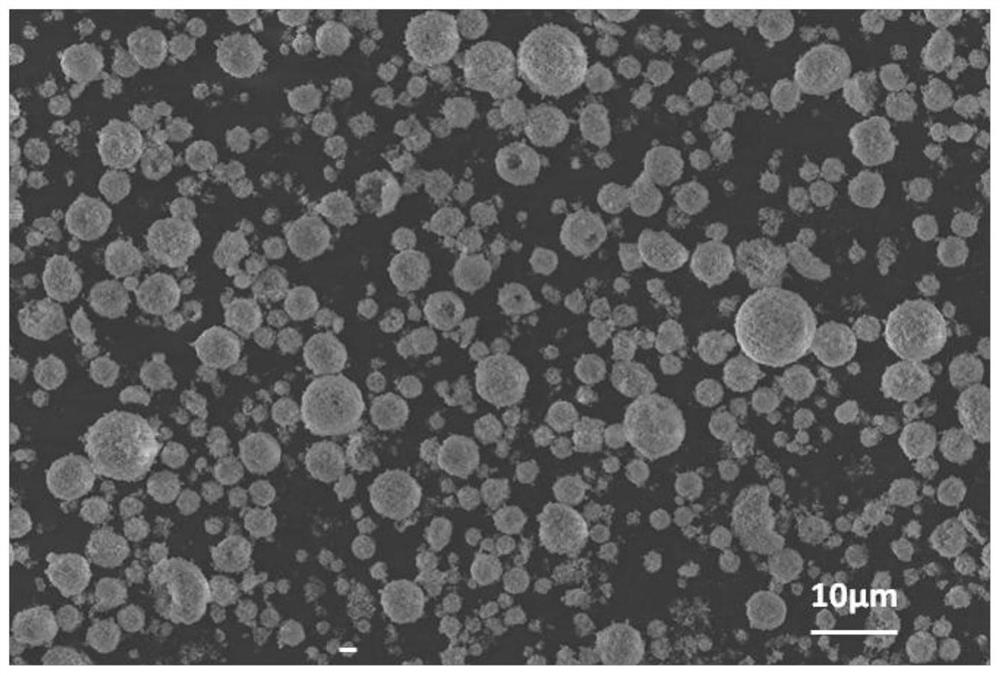

[0044] Weigh Na respectively according to the molar ratio of Na, Ni, Mn, W, B contained in the ratio of 0.67:0.8:0.192:0.008:0.008 2 CO 3 , NiO, Mn 3 o 4 and WB, and then mix the above-mentioned raw materials with water to form a suspension. The above suspension was added to a ceramic grinder, and grinded at a speed of 2500r / min for 1.2h to obtain a slurry. The above slurry was spray-dried under the conditions of 180° C. and 0.2 MPa to obtain precursor material powder. Such as figure 1 The precursor material powder shown has a D50 of 100 nm for the primary particles and a D50 of 3.4 μm for the secondary particles.

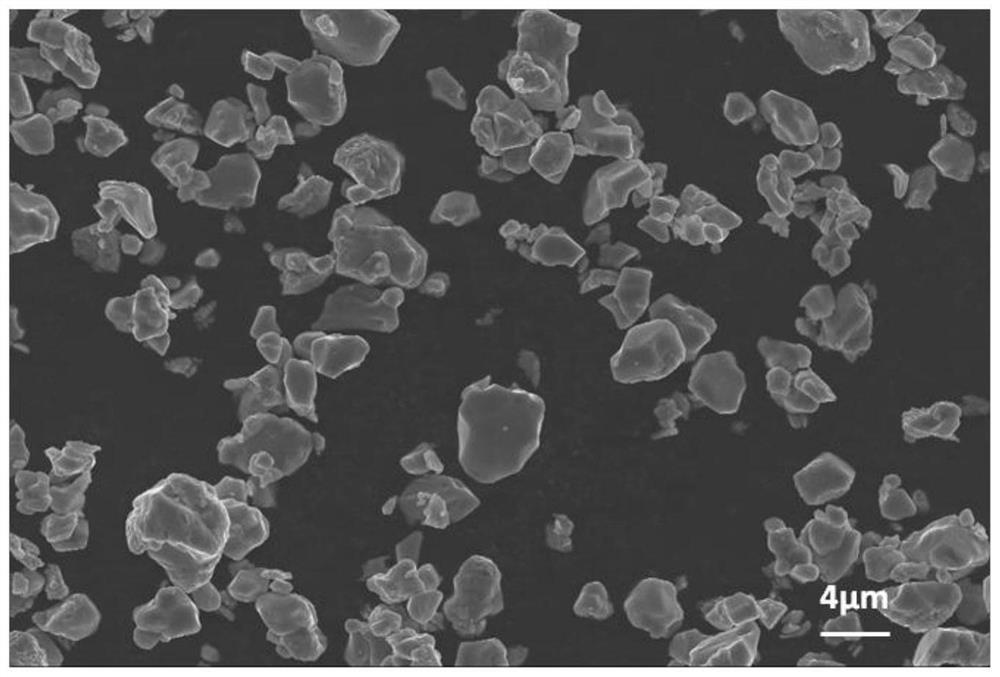

[0045] The first sintering treatment is carried out on the above-mentioned precursor material powder in an air atmosphere, and the temperature of the first sintering treatment is 860 ° C, and the time is 10 hours. After the first sintering treatment is completed, the product is cooled, crushed, and sieved (screening aperture The size is 38 μm) to obtain the f...

Embodiment 2

[0048] Weigh Na according to the molar ratio of Na, Ni, Mn, Zr, N contained in the ratio of 0.67:0.75:0.244:0.006:0.006 2 CO 3 , NiO, Mn 3 o 4 , ZrN, and then mix the above-mentioned raw materials with water to form a suspension. The above suspension was added to a ceramic grinder, and ground at a speed of 2000r / min for 1 hour to obtain a slurry. The above slurry was spray-dried under the conditions of 180° C. and 0.1 MPa to obtain precursor material powder. The D50 of the primary particle of the precursor material powder was tested to be 350 nm, and the D50 of the secondary particle was 5 μm.

[0049] The above powder is subjected to the first sintering treatment in an air atmosphere, and the temperature of the first sintering treatment is 880° C., and the time is 10 hours. After the first sintering treatment is completed, the product is cooled, crushed, and sieved (the sieve aperture size is 38 μm ) to obtain the first sintered product. The first sintered product obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com