Modified hydroxypropyl chitosan adhesive self-healing hydrogel as well as preparation method and application thereof

A technology of hydroxypropyl chitosan and hydrogel, which is applied in the field of functional polymers, can solve problems such as easy damage, and achieve the effects of good swelling performance, easy industrialization, excellent adhesion and self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

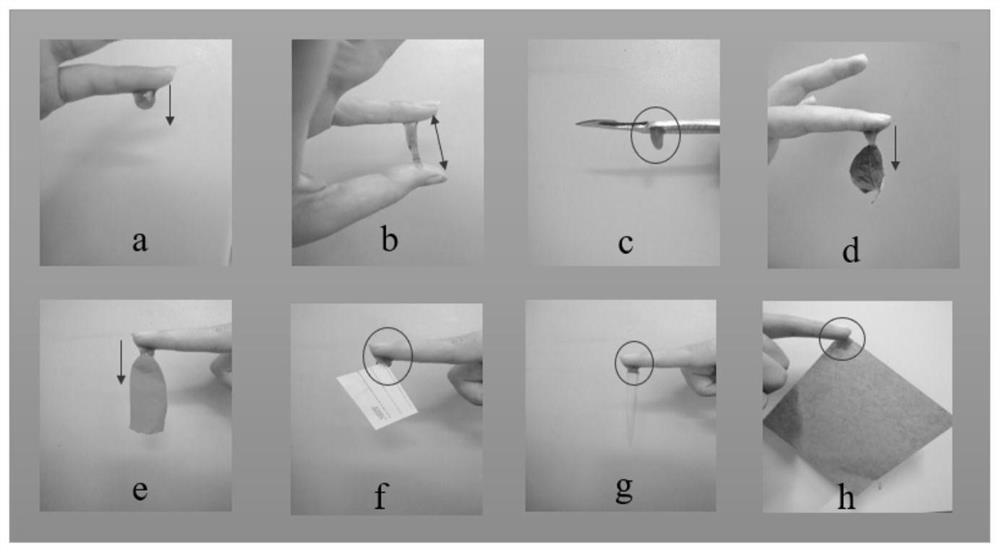

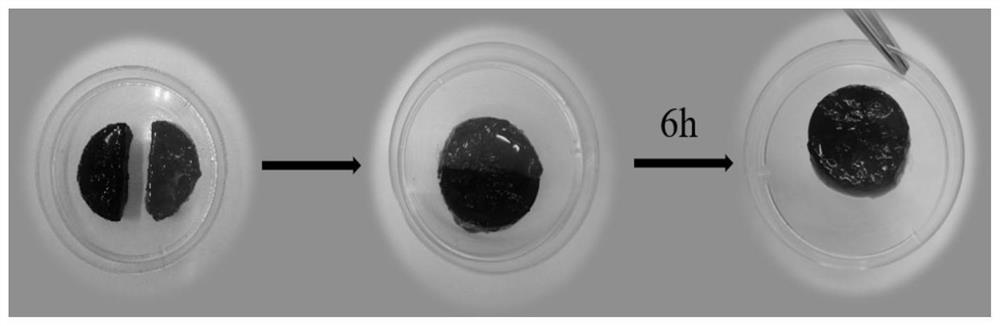

Image

Examples

Embodiment 1

[0043] 1) Weigh 1 g of hydroxypropyl chitosan and dissolve it in 100 mL of deionized water, stir magnetically at room temperature until it dissolves evenly, and adjust the pH to 5.6.

[0044] 2) Another 1g of caffeic acid was weighed and dissolved in 40mL of ethanol aqueous solution (deionized water: absolute ethanol = 1:1), magnetically stirred until dissolved evenly, and then 2g of 1-(3-dimethylaminopropyl)- 3-Ethylcarbodiimide hydrochloride was activated for 2 hours, then added to the above-mentioned hydroxypropyl chitosan solution, and reacted for 24 hours under the protection of nitrogen and protected from light.

[0045] 3) The obtained crude product was dialyzed in deionized water for 3 days, and dried to obtain caffeic acid-modified hydroxypropyl chitosan derivatives.

[0046] 4) Weigh 267mg of caffeic acid-modified hydroxypropyl chitosan derivative into a beaker, add 3mL of deionized water, and magnetically stir until it dissolves evenly.

[0047]5) Weigh 80mg of acr...

Embodiment 2

[0053] 1) Weigh 1 g of hydroxypropyl chitosan and dissolve it in 100 mL of deionized water, stir magnetically at room temperature until it dissolves evenly, and adjust the pH to 5.6.

[0054] 2) Another 1g of caffeic acid was weighed and dissolved in 40mL of ethanol aqueous solution (deionized water: absolute ethanol = 1:1), magnetically stirred until dissolved evenly, and then 2g of 1-(3-dimethylaminopropyl)- 3-Ethylcarbodiimide hydrochloride was activated for 2 hours, then added to the above-mentioned hydroxypropyl chitosan solution, and reacted for 24 hours under the protection of nitrogen and protected from light.

[0055] 3) The obtained crude product was dialyzed in deionized water for 3 days, and dried to obtain caffeic acid-modified hydroxypropyl chitosan derivatives.

[0056] 4) Weigh 160 mg of caffeic acid-modified hydroxypropyl chitosan derivative into a beaker, add 3 mL of deionized water, and stir magnetically until it dissolves evenly.

[0057] 5) Weigh 80mg of ...

Embodiment 3

[0061] 1) Weigh 1 g of hydroxypropyl chitosan and dissolve it in 100 mL of deionized water, stir magnetically at room temperature until it dissolves evenly, and adjust the pH to 5.6.

[0062] 2) Another 1g of caffeic acid was weighed and dissolved in 40mL of ethanol aqueous solution (deionized water: absolute ethanol = 1:1), magnetically stirred until dissolved evenly, and then 2g of 1-(3-dimethylaminopropyl)- 3-Ethylcarbodiimide hydrochloride was activated for 2 hours, then added to the above-mentioned hydroxypropyl chitosan solution, and reacted for 24 hours under the protection of nitrogen and protected from light.

[0063] 3) The obtained crude product was dialyzed in deionized water for 3 days, and dried to obtain caffeic acid-modified hydroxypropyl chitosan derivatives.

[0064] 4) Weigh 160 mg of caffeic acid-modified hydroxypropyl chitosan derivative into a beaker, add 3 mL of deionized water, and stir magnetically until it dissolves evenly.

[0065] 5) Weigh 120mg of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com