Preparation method of hyperbranched modified cellulose wood adhesive

A wood adhesive and cellulose technology, applied in the direction of cellulose derivative adhesives, etc., can solve the problems of poor water resistance, and achieve the effect of low price, excellent water resistance, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]

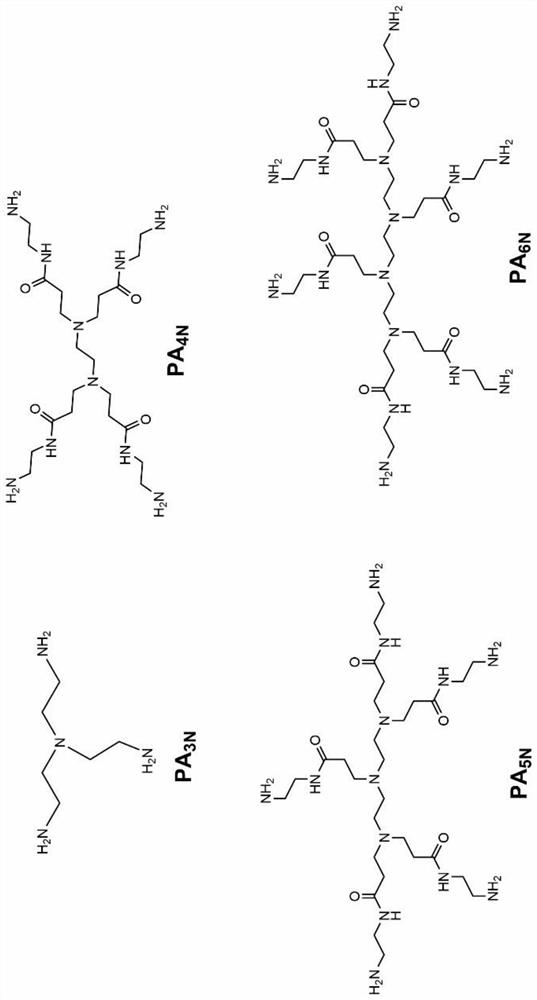

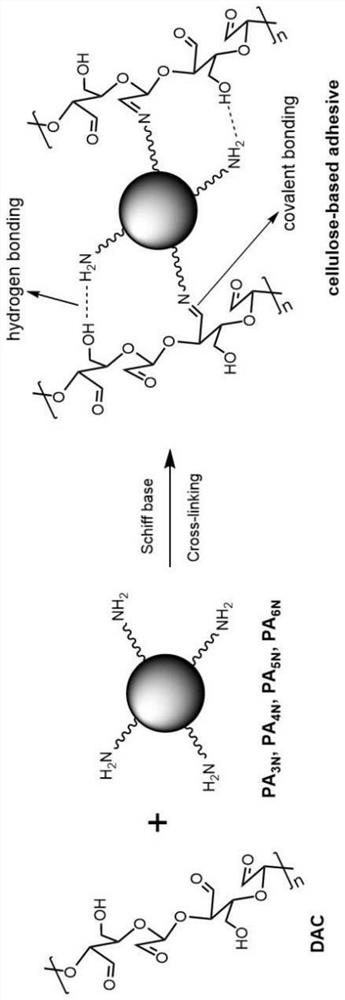

[0026] Such as Figure 1 to Figure 4 Shown, the preparation method of a kind of hyperbranched modified cellulose wood adhesive of the present invention comprises the steps:

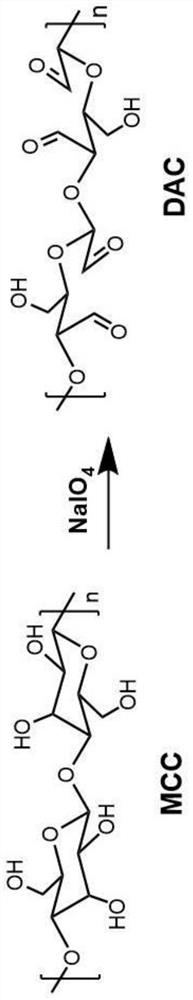

[0027] (1) Under magnetic stirring, add 2.5L deionized water, 50g microcrystalline cellulose MCC, 80g sodium periodate NaIO to the reactor successively 4 Stir at a constant speed and avoid light for 72 hours;

[0028] (2) After the reaction, the solution in the reactor in step (1) was centrifuged and washed at 10,000 rpm for 5 min, and the number of washings was 3 times. Freeze-drying obtains 37.5g dialdehyde cellulose DAC;

[0029] (3) Under magnetic stirring, add 22g of deionized water, 9.0g of dialdehyde cellulose DAC and 9.0g of PA to the reactor in sequence 3N , dialdehyde cellulose DAC and PA 3N The mass ratio is 11, the total solid content of the adhesive is 45%, the reaction condition is 70°C, 10h, and the binary synergistic copolymerization is used to prepare the cellulose-based p...

Embodiment 2

[0032] The difference between Example 2 and Example 1 is that in step (3), under magnetic stirring, 22g of deionized water, 7.2g of dialdehyde cellulose DAC and 10.8g of PA 3N , dialdehyde cellulose DAC and PA 3N The mass ratio is 46, the overall solid content of the adhesive is 45%, and the cellulose-based polymer wood adhesive is prepared by binary synergistic copolymerization.

Embodiment 3

[0034] The difference between Example 3 and Example 1 is that in step (3), under magnetic stirring, 22g deionized water, 10.8g dialdehyde cellulose DAC and 7.2g PA 3N , dialdehyde cellulose DAC and PA 3N The mass ratio is 64, the overall solid content of the adhesive is 45%, and the cellulose-based polymer wood adhesive is prepared by binary synergistic copolymerization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com